Intelligent automatic ultrasonic detection system and method for in-service basin-type insulators

A basin-type insulator, ultrasonic testing technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. , to achieve the effect of rapid detection and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

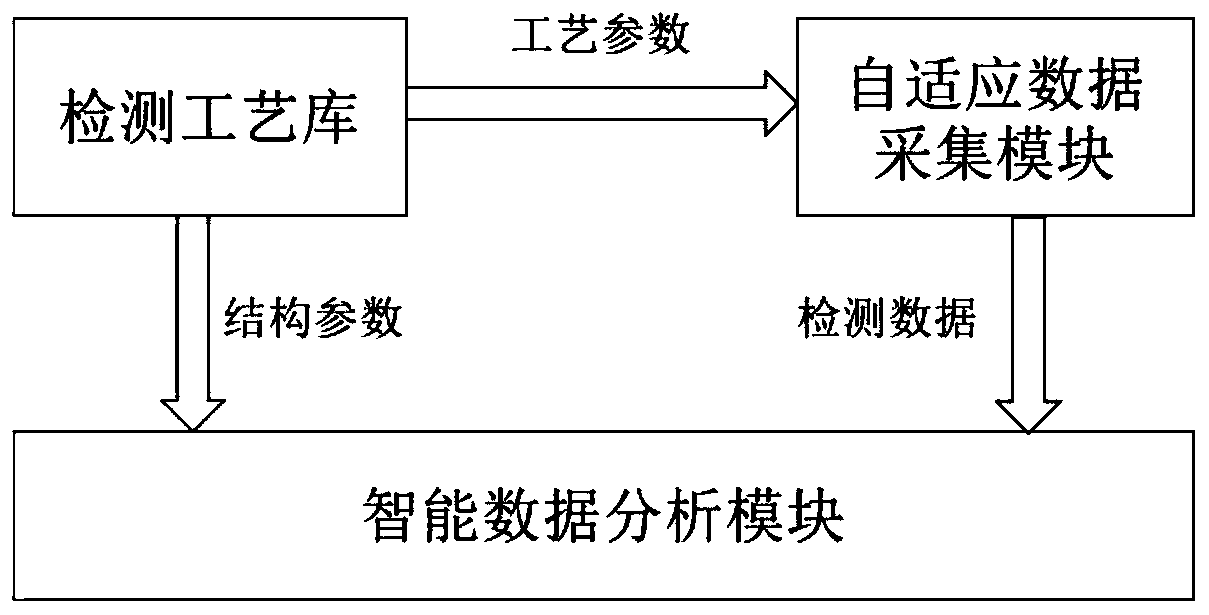

[0029] This embodiment provides an intelligent automatic ultrasonic detection system for pot insulators in service, such as figure 1 As shown, the intelligent automatic ultrasonic testing system is composed of a testing process library, an adaptive data acquisition module and an intelligent data analysis module; Provide the process parameters that need to be set, and provide the geometric structure parameters of the insulator for the intelligent data analysis module; the self-adaptive data acquisition module provides detection data for the intelligent data analysis module; Corresponding relationship of data to realize automatic location of defects;

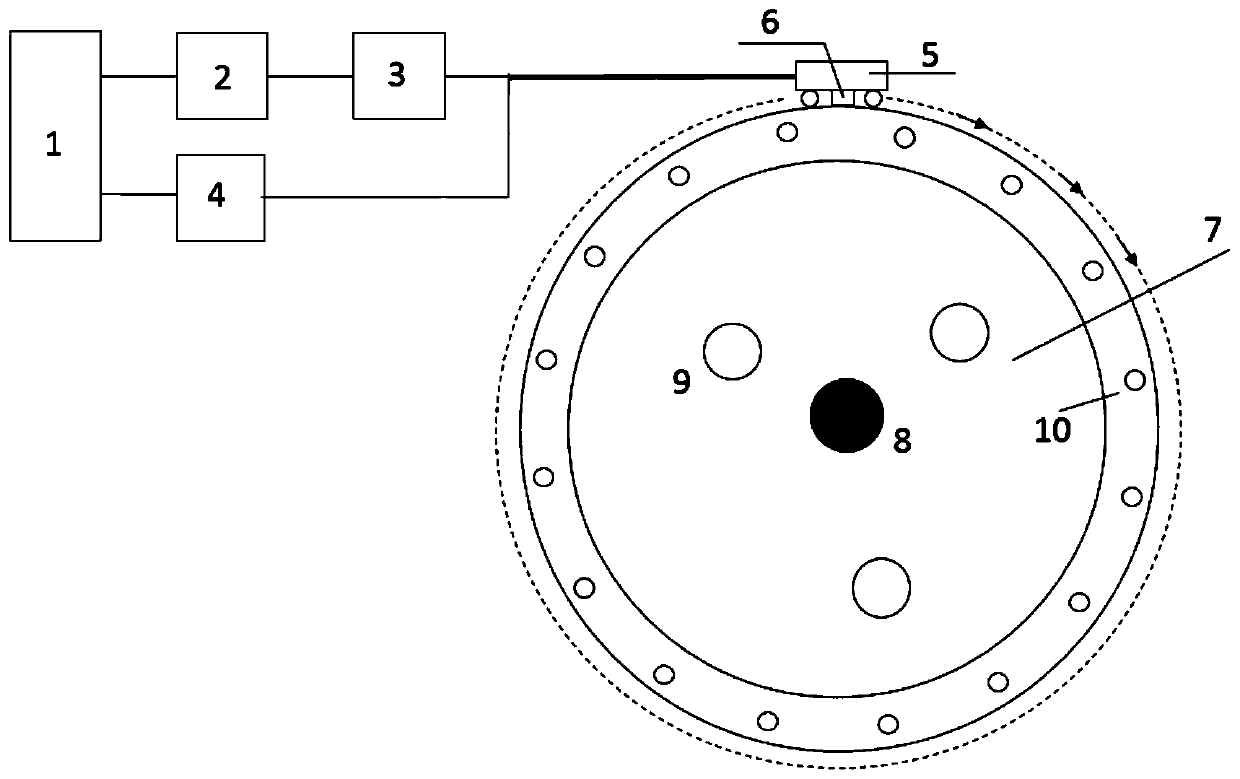

[0030] like figure 2 As shown, the adaptive acquisition module includes a high-energy ultrasonic pulse transceiver device 3, an automatic scanning device 5, an ultrasonic transducer 6, a data acquisition card 2, a control card 4 and a computer 1, and the computer 1 is connected to the data acquisition device respectively. The c...

Embodiment 2

[0032] This embodiment provides an intelligent automatic ultrasonic detection method for pot insulators in service, which uses the intelligent automatic ultrasonic detection system described in Embodiment 1 to detect internal defects of pot insulators in service, such as figure 2 As shown, the detection method includes the following steps:

[0033] (1) Measure the specific detection object, obtain the diameter of the pot insulator 7, the position coordinates and diameter of the central insert 8, the position coordinates and diameter of the through hole 9, and the position coordinates and diameter of all threaded holes 10;

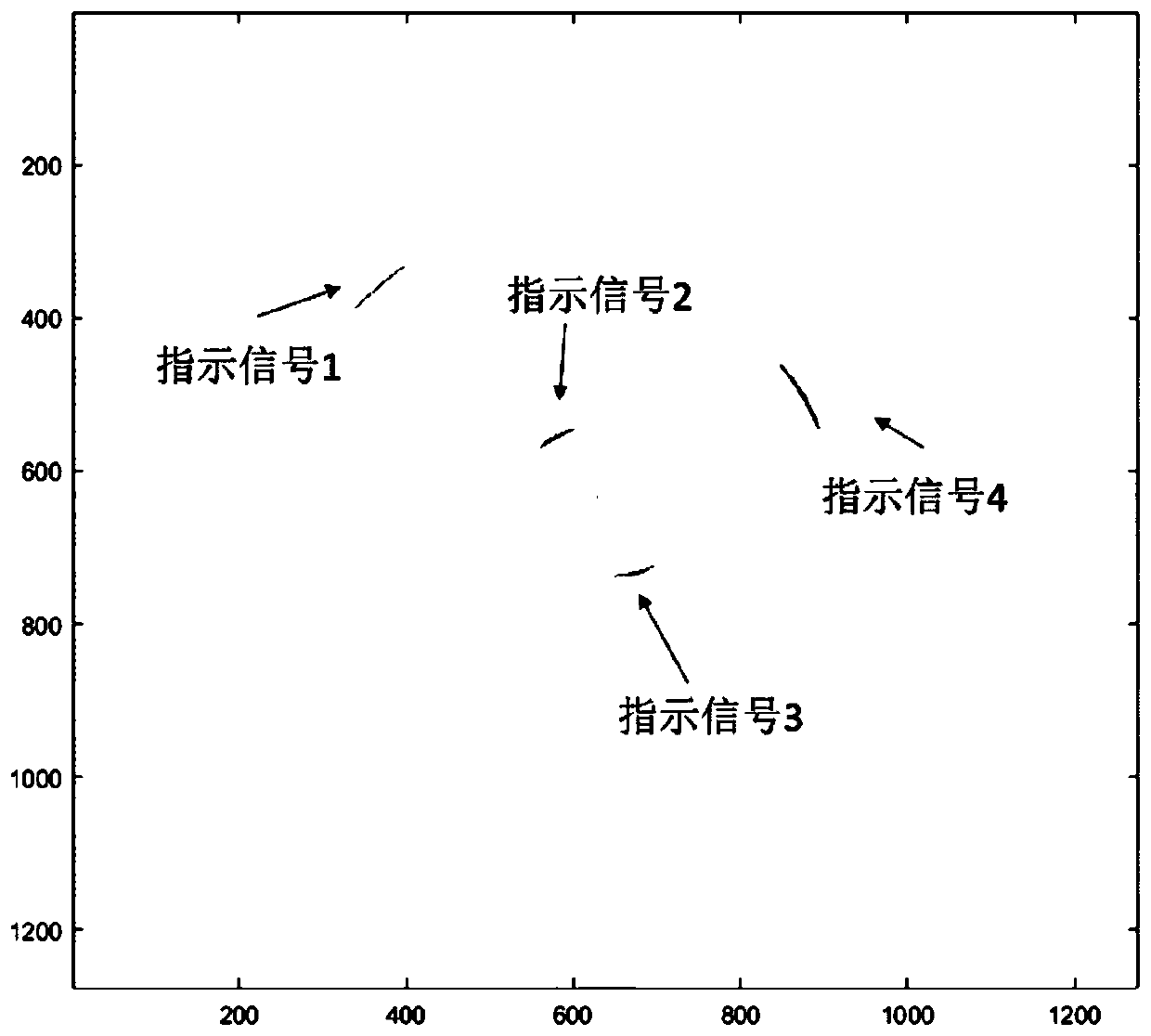

[0034] (2) Select the structural form of the pot insulator from the detection process library, and import the measured geometric parameters to form a two-dimensional cross-sectional view of the detection object. According to the main sound line of the transducer and the threaded hole representing the interior of the pot insulator , the circular intersectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com