Fuel cell film electrode catalyst, and preparation method and application thereof

A fuel cell membrane and electrode catalyst technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of lack of design of three-phase interface channels of catalysts, effective regulation of catalyst lack, and reduction of catalyst reaction areas, etc. Hydrophobic exhaust characteristics, favorable gas transmission, ultra-long stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a fuel cell membrane electrode catalyst, comprising the following steps:

[0037] S1. Dissolving the transition metal cation source compound in the first solvent to obtain the first solution;

[0038] Dissolving the organic nitrogen-containing ligand in a second solvent to obtain a second solution;

[0039] Dispersing the porous conductive carbon material in a third solvent to obtain a suspension;

[0040] S2. After mixing the first solution and the second solution, they are mixed with the suspension for adsorption, and separated to obtain a solid phase substance;

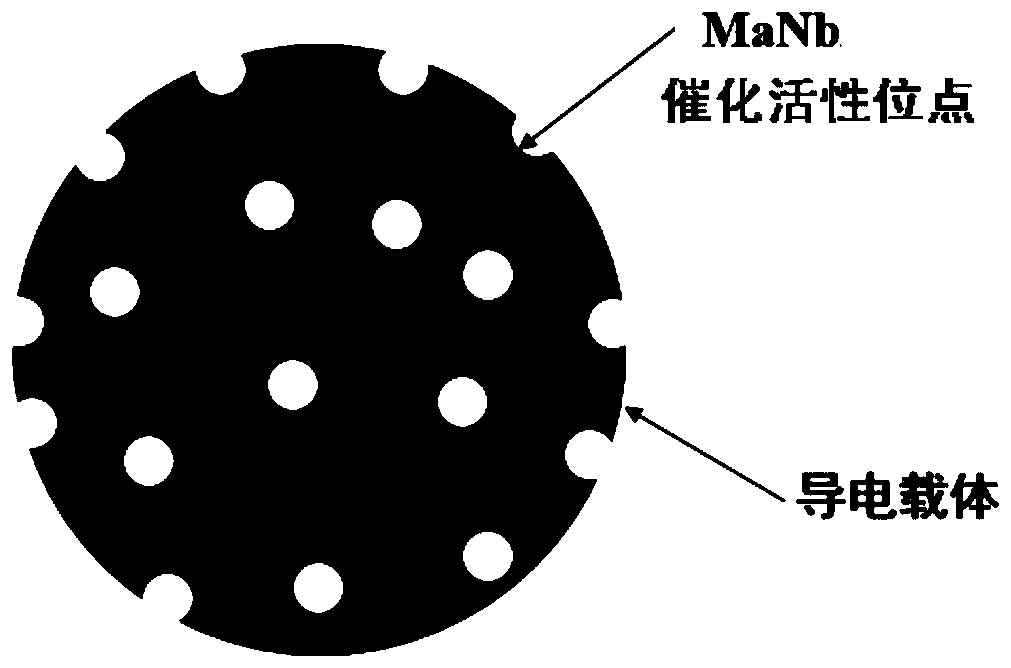

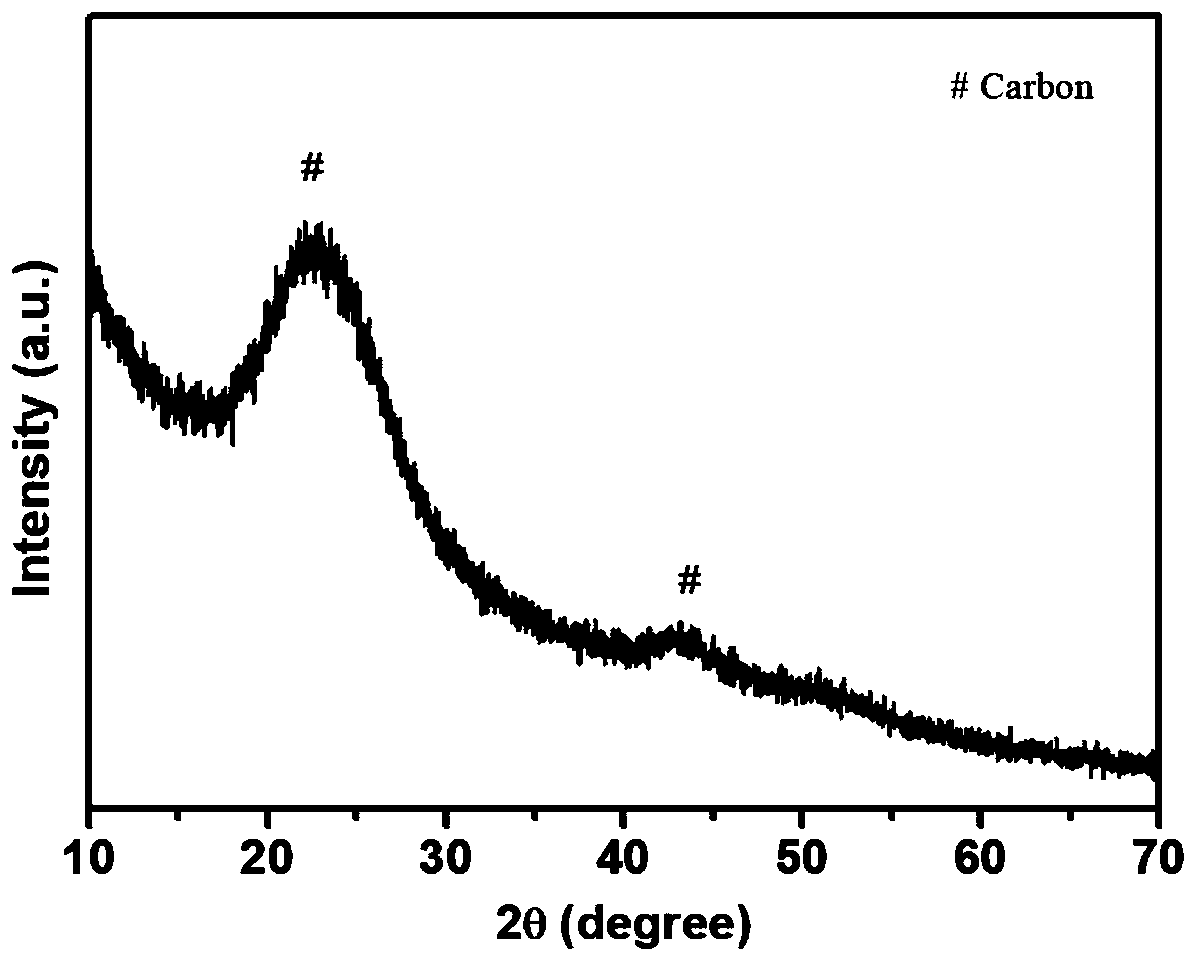

[0041] S3, reacting the solid-phase substance through annealing treatment to obtain a fuel cell membrane electrode catalyst; the fuel cell membrane electrode catalyst includes a porous conductive carbon carrier, and transition metals and nitrogen loaded in the internal pores of the carrier;

[0042] The first solvent and the second solvent are independently sel...

Embodiment 1

[0065] Weigh 0.5g of ferric nitrate, add 30mL of deionized water and 10mL of ethanol into a beaker with a volume of 100mL, and stir for 5 minutes with a magnetic stirrer; weigh 0.1g of polyethyleneimine (Aladdin Company, M.W.600, 99 %, product number E107007-25g, the same as in the following examples) was added into the above mixed solution, and the stirring was continued to obtain the first solution after 10 minutes.

[0066] Weigh 4g of dicyandiamide, add 100mL of deionized water into a beaker with a volume of 500mL, stir with a magnetic stirrer for 30min, and obtain the second solution. Pour the first solution into it, and continue heating and stirring for 1 h to obtain a mixed solution of the first solution and the second solution.

[0067] Add 4 g of conductive carbon black BP2000 (produced by Cabot Corporation of the United States, which can be purchased directly) into 200 mL of ethylene glycol, stir with a magnetic stirrer for 10 min, and then use an ultrasonic cleaner ...

Embodiment 2

[0074] Weigh 0.5g of cobalt nitrate, add 30mL of deionized water and 10mL of ethanol into a beaker with a volume of 100mL, and stir for 5 minutes with a magnetic stirrer; weigh 0.1g of polyethyleneimine and add it to the above mixed solution, and continue stirring , the first solution was obtained after 10 minutes.

[0075] Weigh 1 g of 2,2-bipyridine, add it into a beaker containing 100 mL of deionized water and a volume of 500 mL, stir with a magnetic stirrer for 30 min, and obtain the second solution. Pour the first solution into it, and continue heating and stirring for 1 h to obtain a mixed solution of the first solution and the second solution.

[0076] Add 2 g of conductive carbon black EC-600JD (Lion Corporation, Japan) into 200 mL of ethylene glycol, stir with a magnetic stirrer for 10 min, and then use an ultrasonic cleaner for ultrasonic treatment. After 30 min, a uniformly dispersed suspension is obtained.

[0077] The mixed solution of the first solution and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com