Motor rotor punching sheet, permanent magnet driving motor rotor body and permanent magnet driving motor

A technology for motor rotor and rotor punching, which is applied in the direction of electric components, magnetic circuit rotating parts, magnetic circuit, etc., can solve the problems of weakening the harmonic magnetomotive force, the effect is not obvious, and the balance of the motor stator and rotor is affected. It achieves the effects of high sine distribution of magnetic field, small influence of harmonic magnetic field, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

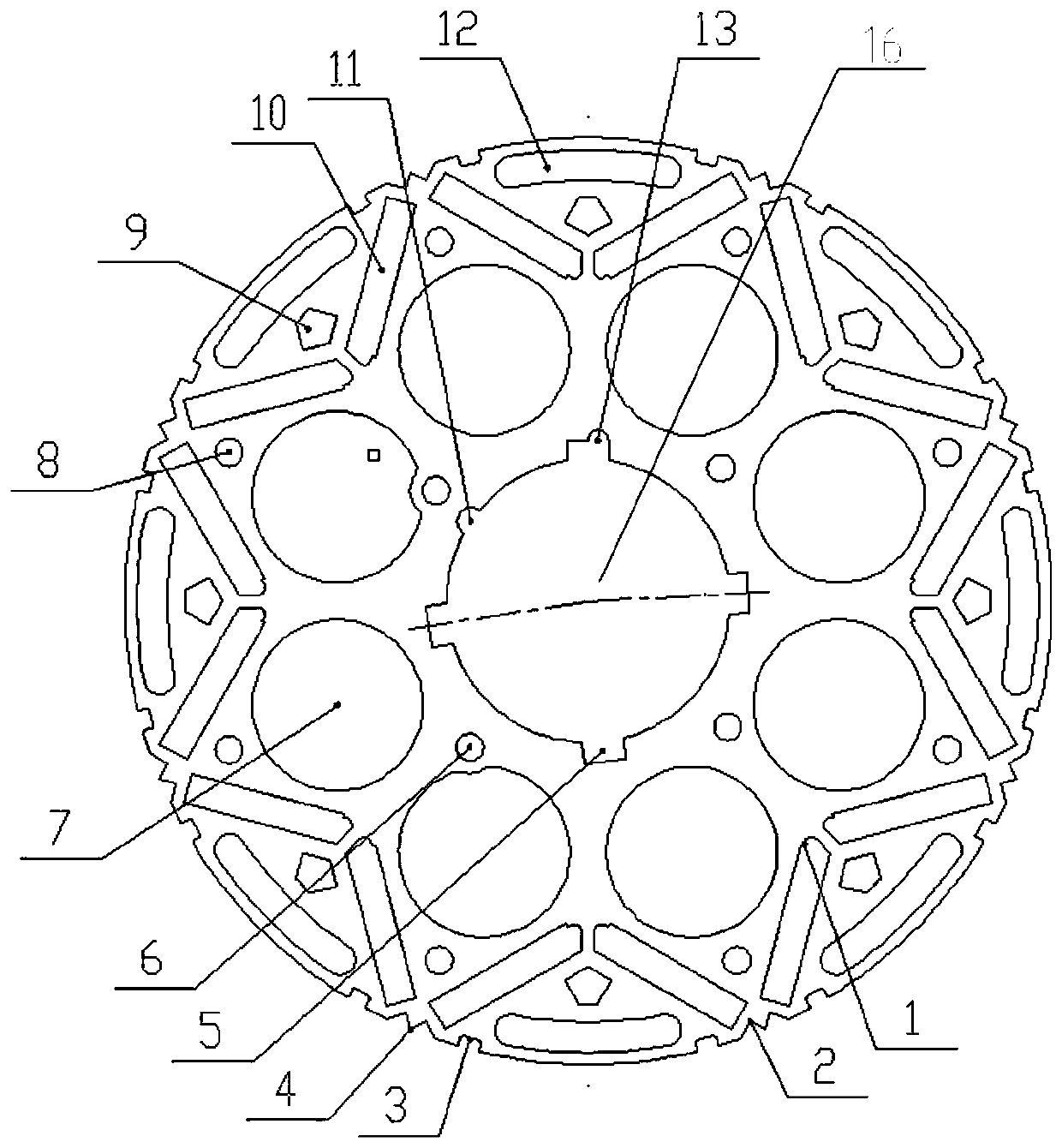

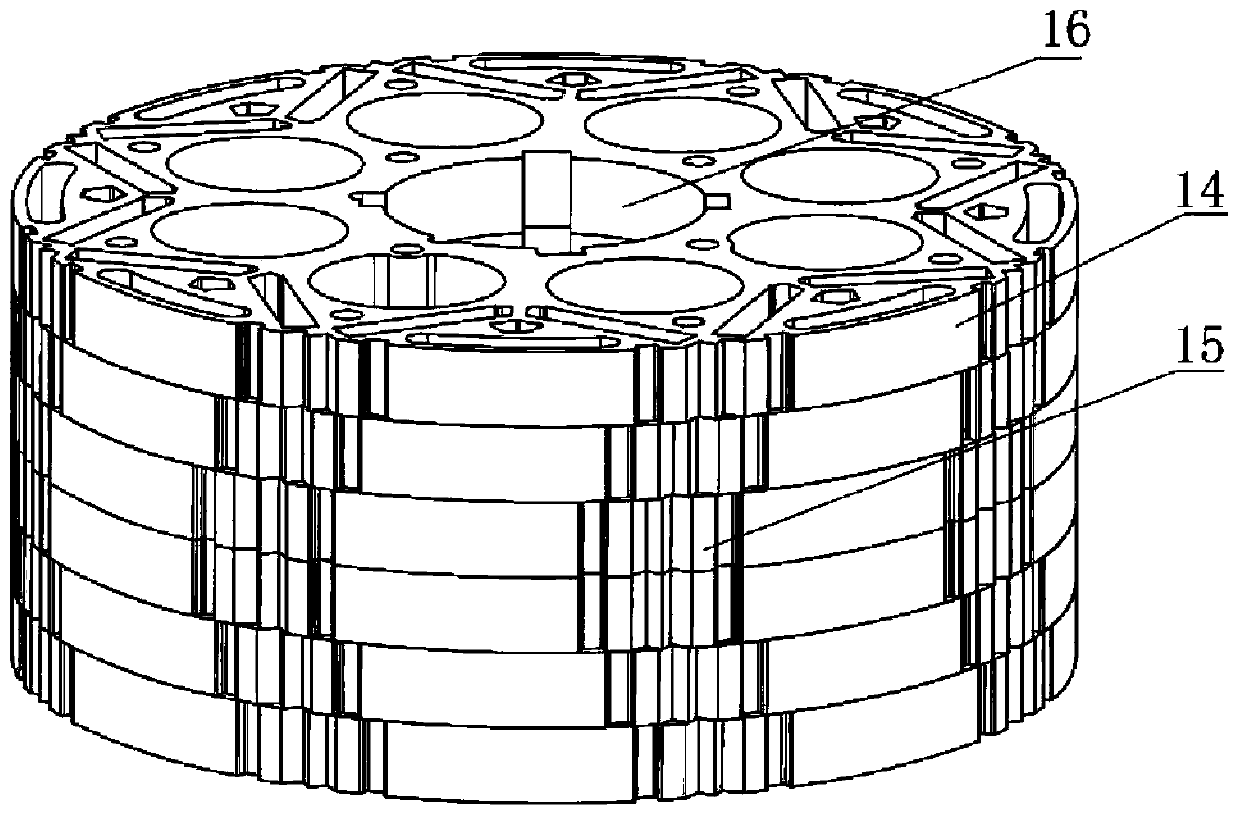

[0026] Such as figure 1 A kind of motor rotor stamping shown, comprises rotating shaft hole 16, is also formed with to place permanent magnet on the rotor stamping, is evenly distributed on the same circumference, and several permanent magnet slots concentric with rotating shaft hole 16, two adjacent permanent magnet slots The magnet slots are combined to form a U-shaped or V-shaped structure, and the permanent magnets are embedded in the permanent magnet slots in an alternating manner of N poles and S poles. The permanent magnet embedded in the rotor body of the motor is segmented, and the height of the rotor is set according to the power, speed, and torque of the permanent magnet motor for vehicles. When running at constant power and high speed, the permanent magnet of the motor has large magnetic flux leakage and weak magnetic speed-up capability Strong, low-speed motor flux leakage is small, the output torque is large, so the torque ripple is small, the control system has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com