Homopolypropylene and preparation method therefor

A homopolypropylene, weight-average molecular weight technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of lack of proper development of homopolypropylene, insufficient processability, strength deterioration, etc., and achieve excellent processability, roughness Texture, effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

comparative preparation Embodiment 1

[0158] Step 1: Preparation of transition metal compound

[0159]

[0160] The catalyst of the above chemical formula is prepared by the following method.

[0161] 2-Methyl-4-tert-butylphenylindene (20.0g, 76mmol) was dissolved in toluene / THF=10 / 1 (230mL), and the n-butyllithium solution (2.5 M, hexane solvent, 22 g), and stirring was performed at room temperature for one day. Then, (6-tert-butoxyhexyl)dichloromethylsilane (1.27 g) was slowly added dropwise to the mixed solution at -78°C, stirred for about 10 minutes, and stirred at room temperature for one day. Then, water was added to separate the organic layer, and the solvent was distilled off under reduced pressure to obtain (6-tert-butoxyhexyl)(methyl)-bis(2-methyl-4-tert-butylphenylindenyl)silane.

[0162] Dissolve the pre-prepared (6-tert-butoxyhexyl)(methyl)-bis(2-methyl-4-phenyl)indenylsilane in a solution of toluene / THF=5 / 1 (95mL), in At -78°C, n-butyllithium solution (2.5M hexane solvent, 22g) was slowly added dropwise,...

comparative preparation Embodiment 2

[0166] Step 1: Preparation of transition metal compound

[0167]

[0168] The catalyst of the above formula is prepared by the following method.

[0169] A 250 mL Schlenk flask was charged with 7-tert-butylphenyl-2-methylindene (34.4 mmol) and dried under reduced pressure. Under an argon atmosphere, anhydrous toluene / THF (172 / 34mL) was added for dilution, and then 2.5M n-BuLi hexane solution (36.2mmol, 14.5mL) was slowly added at -25°C. Stir at 25°C for 4 hours or more, add Et to the reactants 2 SiCl 2 (17.2 mmol) and stirring at 25°C overnight. Use a separatory funnel to extract MTBE and H 2 O, then MgSO 4 Add to the organic layer to dry the remaining water. The solid was filtered out with a reduced pressure filter, and the liquid was distilled under reduced pressure to concentrate.

[0170] (Diethylsilane-diyl)-bis(2-methyl-4-(4-tert-butyl-phenyl)indenyl)silane (10.7 mmol) was added to a 100 mL Schlenk flask and dried under reduced pressure. Under an argon atmosphere, anhydrous...

comparative preparation Embodiment 3

[0174] Step 1: Preparation of transition metal compound

[0175]

[0176] The catalyst of the above formula is prepared by the following method.

[0177] A 250 mL Schlenk flask was charged with 7-tert-butylphenyl-2-isopropylindene (10.0 g, 34.4 mmol) and dried under reduced pressure. Under an argon atmosphere, anhydrous ether (172 mL) was added for dilution, and a 2.5M n-BuLi hexane solution (36.2 mmol, 14.5 mL) was slowly added at -25°C. After stirring at 25°C for 4 hours or more, the Me 2 SiCl 2 (68.9 mmol, 8.30 mL) was added to the reaction and stirred at 25°C overnight. LiCl was filtered out using a G4 size glass filter, and the filtrate was dried under reduced pressure. To another 250 mL Schlenk flask was added 7-tert-butylphenyl-2-methylindene (9.04 g, 34.4 mmol) and CuCN (1.72 mmol, 0.15 g) and dried under reduced pressure. Under argon atmosphere, add anhydrous toluene (208mL) and THF (20.4mL) to dilute, slowly add 2.5M n-BuLi hexane solution (36.2mmol, 14.5mL) at -25℃, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

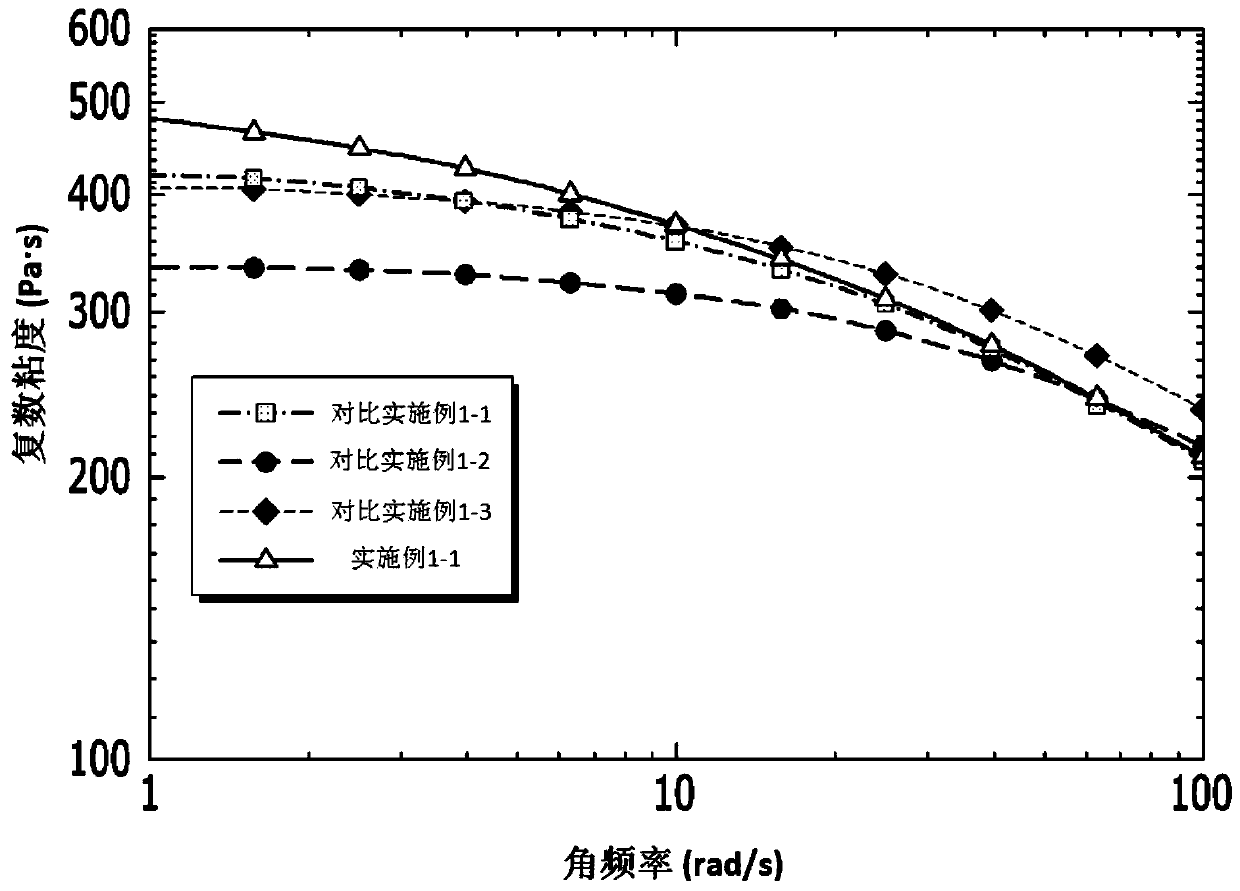

| complex viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com