A kind of improvement method of sulfuric acid saline soil

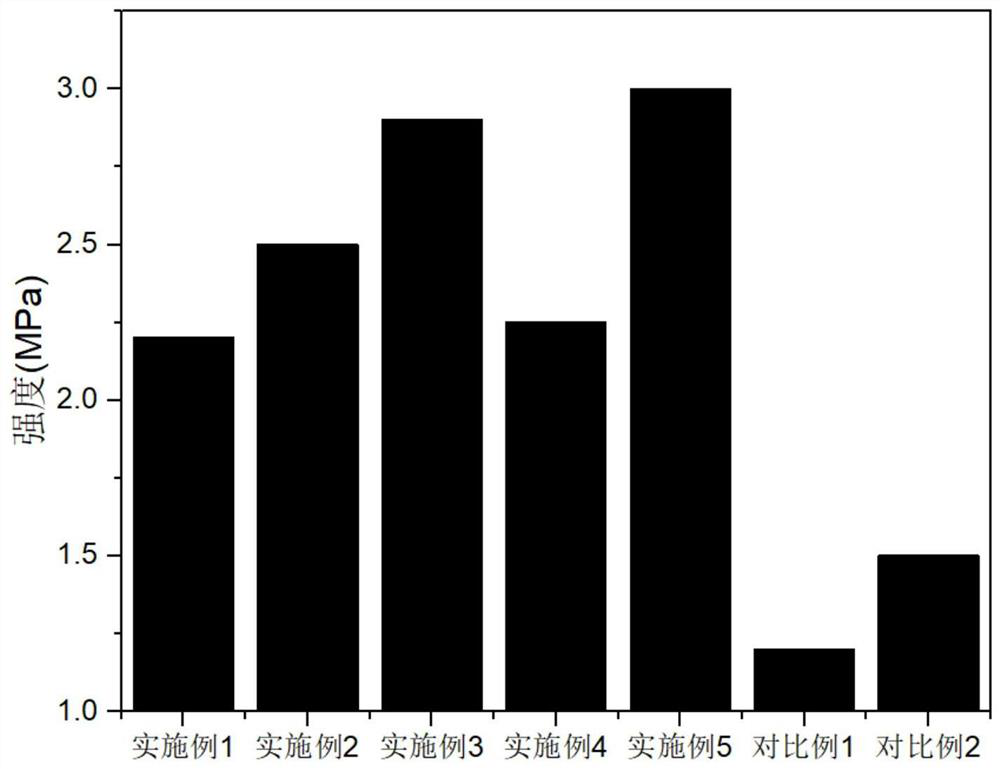

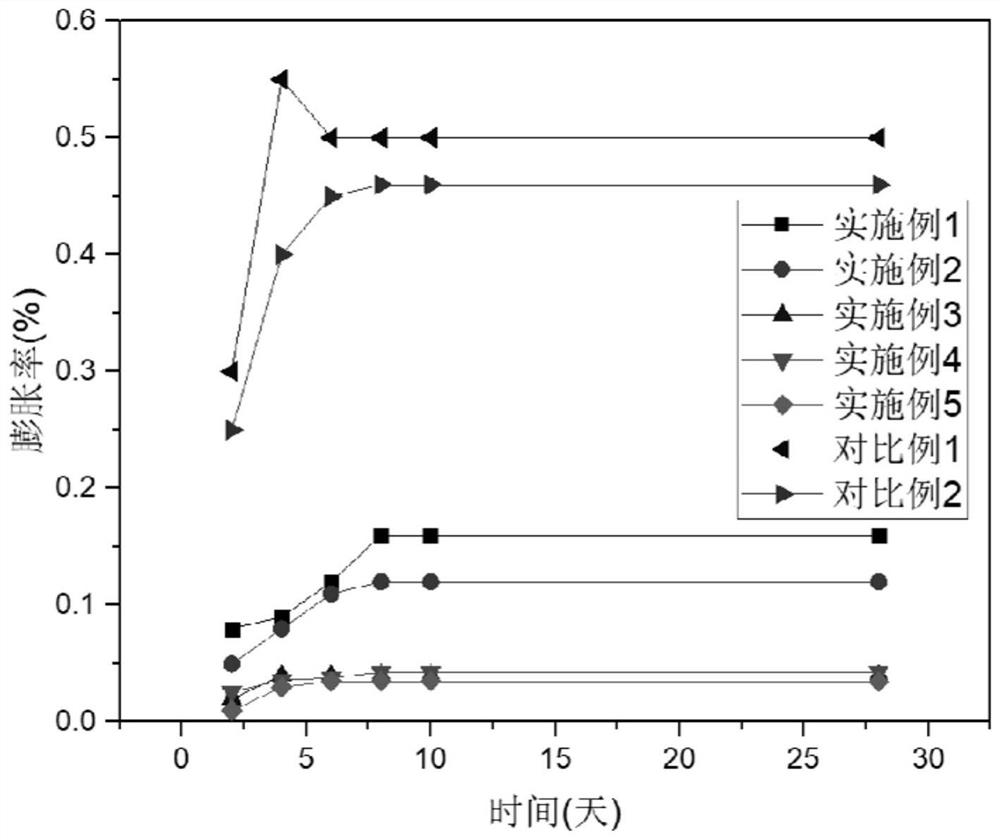

A saline soil and sulfuric acid technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of large expansion and low strength, and achieve the effects of good volume stability, improved compressive strength, and small expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for improving sulfuric acid saline soil, comprising the following steps:

[0024] a) Sulphate saline soil is pulverized and sieved, and cement, fly ash and lime are sieved for subsequent use;

[0025] B) add the fly ash of sulfate saline soil quality 10% in sulfate saline soil, the cement of 8%, the lime mixing of 4%;

[0026] c) Through the compaction test, it is determined that the optimum water content of the soil sample is 20%, and water is added to the mixture, and mixed evenly according to the optimum water content of 20%.

[0027] It is prepared by static compaction method, and standard curing is carried out after molding to obtain compacted samples.

Embodiment 2

[0029] A method for improving sulfuric acid saline soil, comprising the following steps:

[0030] a) Sulphate saline soil is pulverized and sieved, and cement, fly ash and lime are sieved for subsequent use;

[0031] B) add 10% fly ash of sulfate saline soil quality in sulfate saline soil, 8% cement, 8% lime mix;

[0032] c) Through the compaction test, it is determined that the optimum water content of the soil sample is 20%, and water is added to the mixture, and mixed evenly according to the optimum water content of 20%.

[0033] It is prepared by static compaction method, and standard curing is carried out after molding to obtain compacted samples.

Embodiment 3

[0035] A method for improving sulfuric acid saline soil, comprising the following steps:

[0036] a) Sulphate saline soil is pulverized and sieved, and cement, fly ash and lime are sieved for subsequent use;

[0037] B) add 15% fly ash of sulfate saline soil quality in sulfate saline soil, 10% cement, 4% lime mix;

[0038] c) Through the compaction test, it is determined that the optimum water content of the soil sample is 20%, and water is added to the mixture, and mixed evenly according to the optimum water content of 20%.

[0039] It is prepared by static compaction method, and standard curing is carried out after molding to obtain compacted samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com