Composite liquid metal based flexible lead

A technology of liquid metal and flexible wires, applied in liquid conductors, metal/alloy conductors, bendable conductors, etc., can solve problems such as limited working range, poor anti-interference performance, and short service life of flexible wires, and achieve extended work range, ease of processing and mass production, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

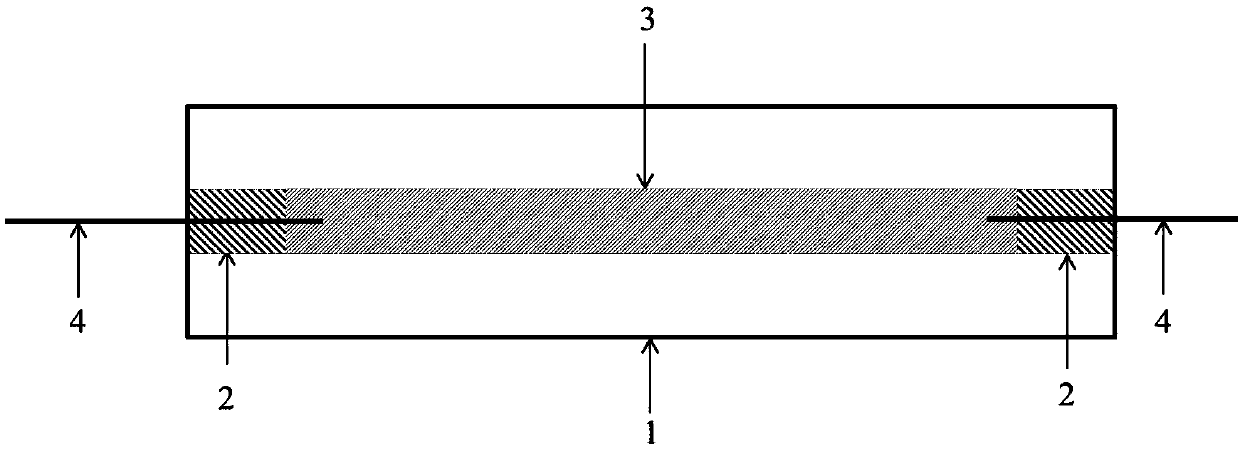

[0038] figure 1 It is a single-layer gallium-bismuth-based composite liquid metal flexible wire according to a preferred embodiment of the present invention, including: an external flexible substrate 1, a solid metal 2 composed of a bismuth-based alloy, a liquid metal 3, and a lead wire 4. figure 1 The middle shaded part is the composite liquid metal line segment. The solid metal segment composed of bismuth-based alloy is located at both ends of the composite liquid metal line segment. 100°C, the room temperature liquid alloy GaIn 24.5 ) The liquid metal segment formed is located in the middle of the metal line segment. The material of the external flexible substrate is polydimethylsiloxane (PDMS). In this embodiment, the composite liquid metal is made into a cylinder with a cross-sectional diameter of 10 μm and a length ranging from 1 mm to centimeters according to the actual situation. The preparation method is a combination of injection method (suitable for liquid metal)...

Embodiment 2

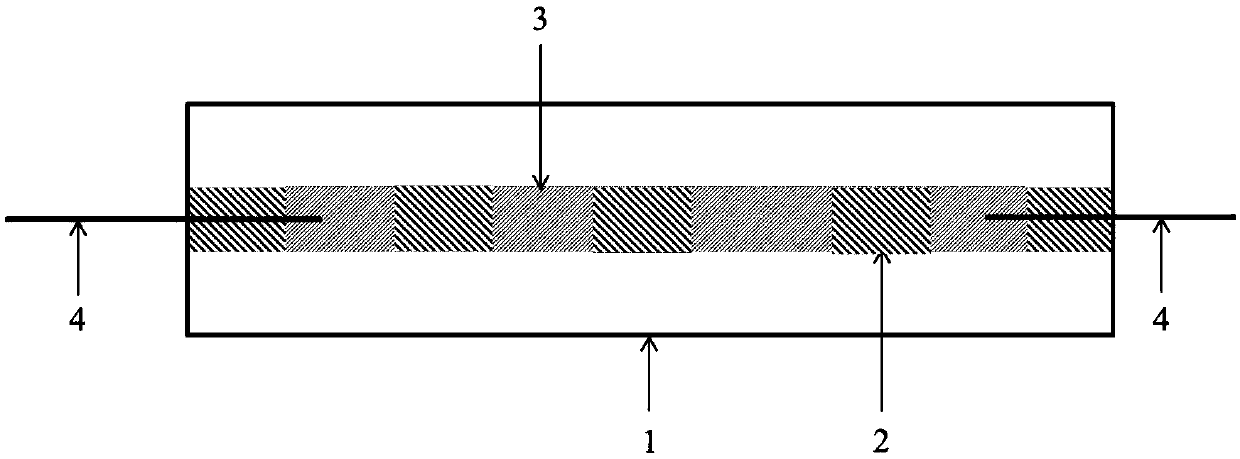

[0043] figure 2 It is a single-layer solid-liquid composite liquid metal flexible wire according to a preferred embodiment of the present invention, including: an external flexible substrate 1 , solid metal 2 , liquid metal 3 , and lead wire 4 . The material of the external flexible substrate is polydimethylsiloxane (PDMS). The composite liquid metal is made into a quadrangular prism with a cross-sectional side length of 30 μm×200 μm, and the preparation method is a combination of an injection method (suitable for liquid metal) and a sputtering method.

[0044] figure 2 The middle shaded part is the composite liquid metal line segment, which includes solid metal segment and liquid metal segment (gallium-based alloy Ga 67 In 20.5 sn 12.5, the liquid alloy is formulated at a heating temperature of 240°C). In this embodiment, the liquid metal has 4 stages, and the solid metal has 5 stages. At normal temperature, the two metals form complementary properties. As shown in Fi...

Embodiment 3

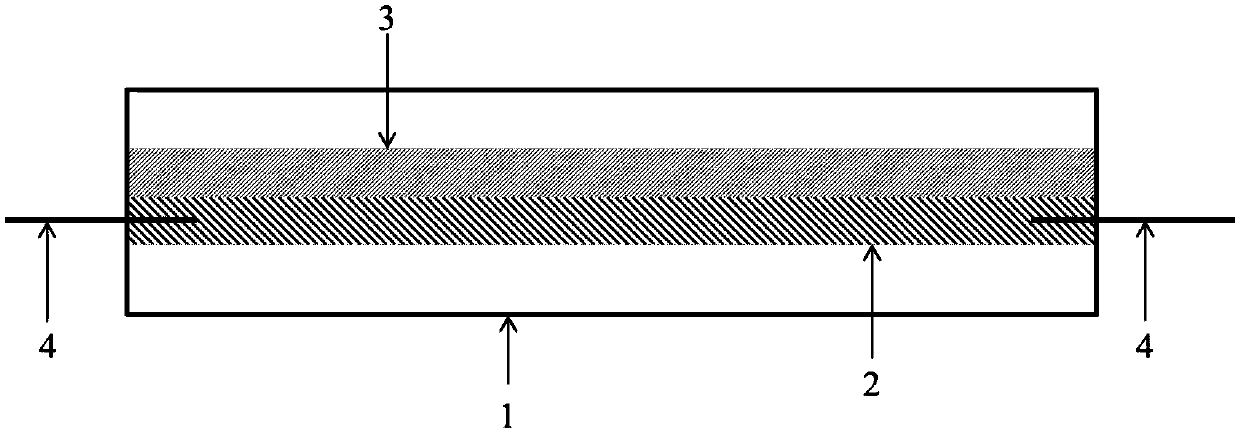

[0047] According to a preferred embodiment of the present invention, a multilayer gallium-bismuth-based composite liquid metal flexible wire includes: an external flexible substrate 1 , solid metal 2 , liquid metal 3 , and leads 4 . Composite liquid metal consists of 2 layers ( Figure 3a ) or 3 layers ( Figure 3b ) composed of liquid metal 3 and solid metal 2 at normal temperature, and the liquid metal 3 and solid metal 2 are arranged alternately. The shaded part in the figure is the composite liquid metal segment.

[0048] The three-layer structure prepared in this embodiment can further improve the working reliability of the flexible heat-generating wire. Among them, the solid metal is a bismuth-based alloy (Bi 32.5 In 51 sn 16 .5, the melting point is 60 degrees Celsius), the thickness is 10 microns, and the liquid metal is a gallium-based alloy (Ga 62 In 25 sn 13 The melting point is 11 degrees Celsius) and the thickness is 10 microns. At room temperature, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com