Method used for preparing vertical graphene film taking biomass as raw material

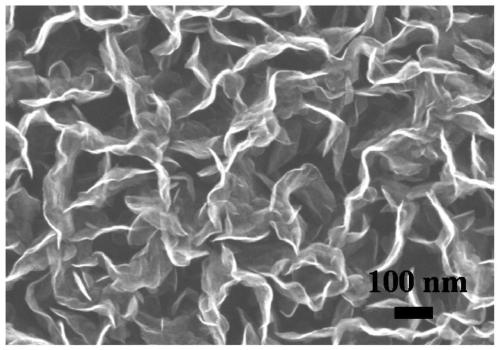

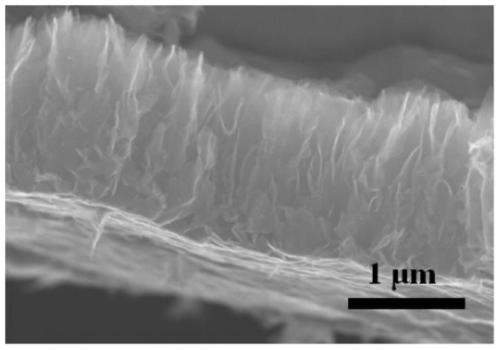

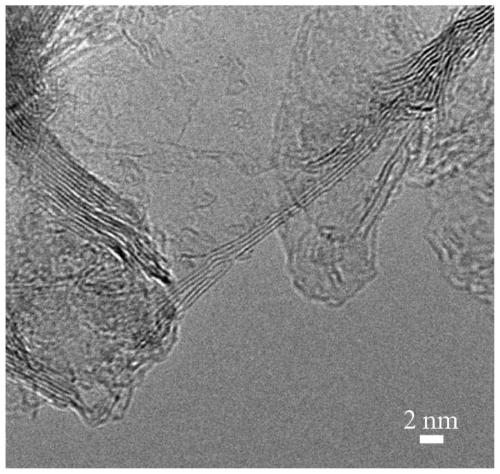

A graphene film and biomass technology, applied in the field of nano-carbon materials, can solve the problem of low yield of vertical graphene film and achieve the effect of high defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The microwave plasma bombardment method is used to prepare vertical graphene film from biomass foam. The specific method is as follows:

[0023] (1) Wash the Ni foil with acetone, alcohol and deionized water successively, dry, and cut into 5mm×6mm slices, and then make small boxes;

[0024] (2) The biomass lignocellulosic foam is crushed with a masher, and the crushed biomass foam is placed in the small box, and then placed in the plasma device (this example uses MPT- produced by Japan High Frequency Co., Ltd.) On the stage in the 1000-02 plasma device), raise the stage to the intersection of the waveguide and the quartz tube;

[0025] (3) Evacuate the reaction chamber of the plasma device for 30 minutes so that the pressure in the chamber reaches 0.1 Torr;

[0026] (4) Introduce 20sccm hydrogen and 20sccm argon into the reaction chamber, and when the pressure stabilizes to 1 Torr, ignite the microwave plasma;

[0027] (5) After the microwave plasma bombards the biomass foam for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com