Single crystal material as well as preparation method and application thereof

A single crystal material and single crystal furnace technology, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of low output rate, small single crystal size, easy cracking, etc., and achieve output The effect of high yield, shortened growth cycle, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

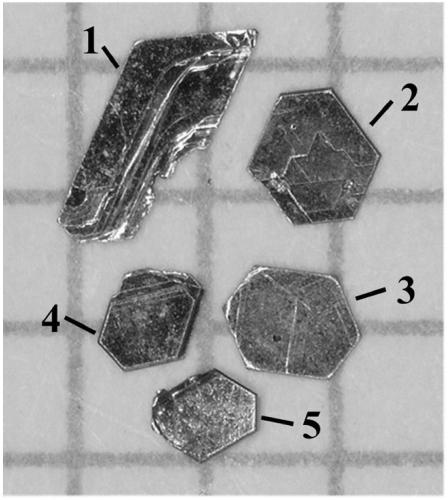

Image

Examples

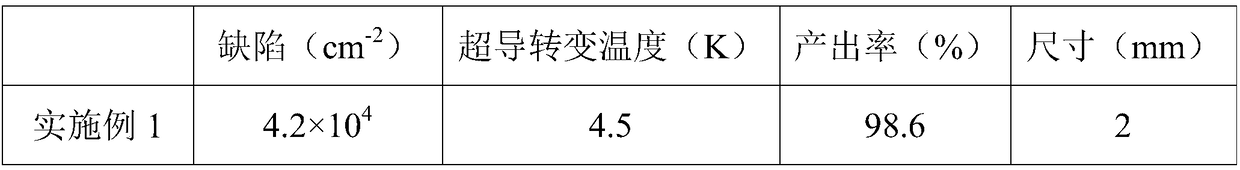

Embodiment 1

[0051] A method for preparing a single crystal material comprises the steps of:

[0052] (1) Mix Ta powder and S powder at a molar ratio of 1:2.5 to obtain a mixed powder, put the mixed powder into an alumina crucible, and place the alumina crucible under vacuum in a single crystal furnace In a quartz tube, raise the temperature to 400°C at a rate of 40°C / h, keep it for 24 hours, then raise it to 950°C at a rate of 55°C / h, keep it for 90 hours, and cool down to room temperature to prepare TaS 2 Polycrystalline;

[0053] (2) the TaS 2 polycrystalline, Cu powder and halogen salt are mixed in a molar ratio of 1:0.09:10, and the halogen salt is a mixture of NaCl and KCl in a molar ratio of 1:1 to obtain a precursor;

[0054] (3) Put the precursor into an alumina crucible, place the alumina crucible in a vacuum quartz tube in a single crystal furnace, heat it to 950°C at a heating rate of 95°C / h, and keep it warm for 24h, Then the product was cooled to 850°C at a rate of 10°C / h,...

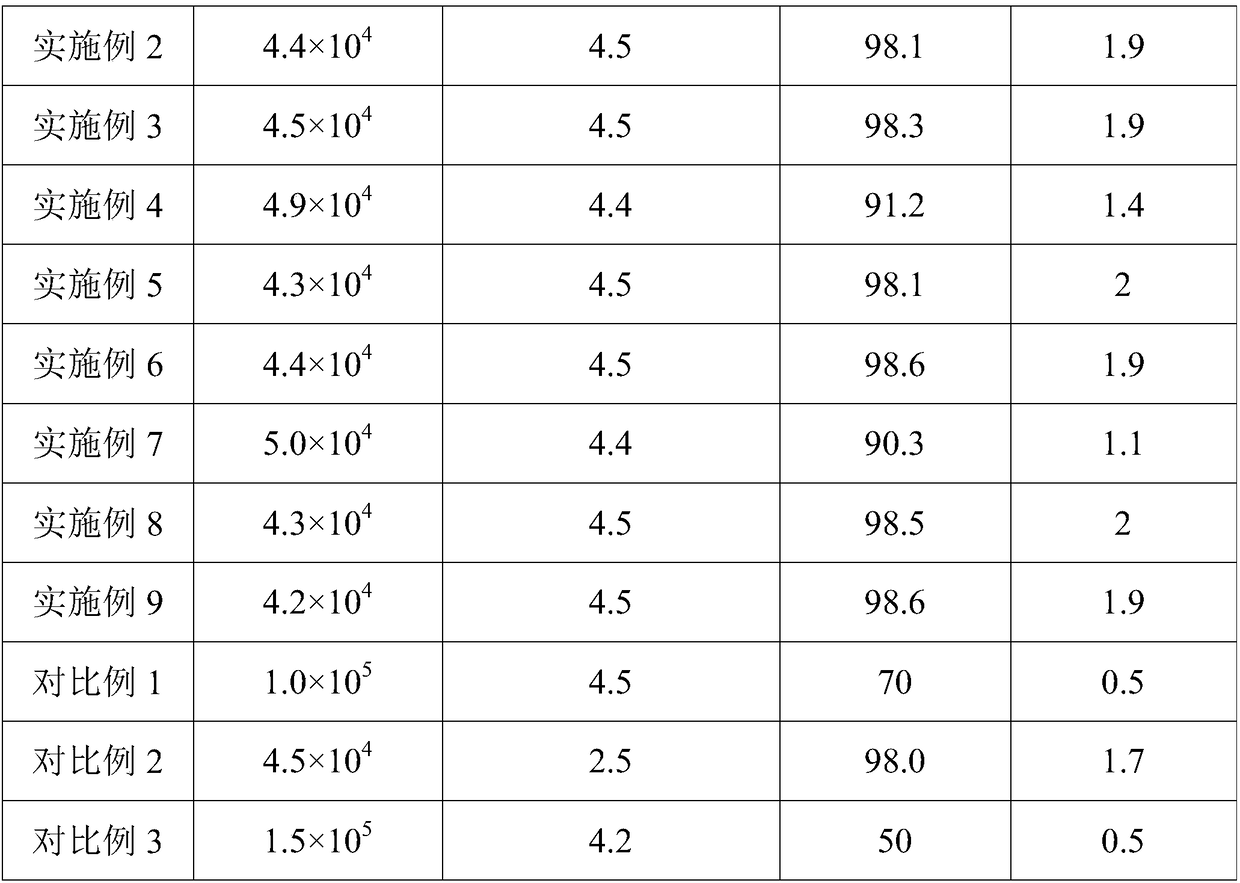

Embodiment 2

[0057] The difference with Example 1 is that the TaS described in step (2) 2 The molar ratio of polycrystalline, Cu powder and halogen salt is 1:0.06:8.

Embodiment 3

[0059] The difference with Example 1 is that the TaS described in step (2) 2 The molar ratio of polycrystalline, Cu powder and halogen salt is 1:0.16:12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com