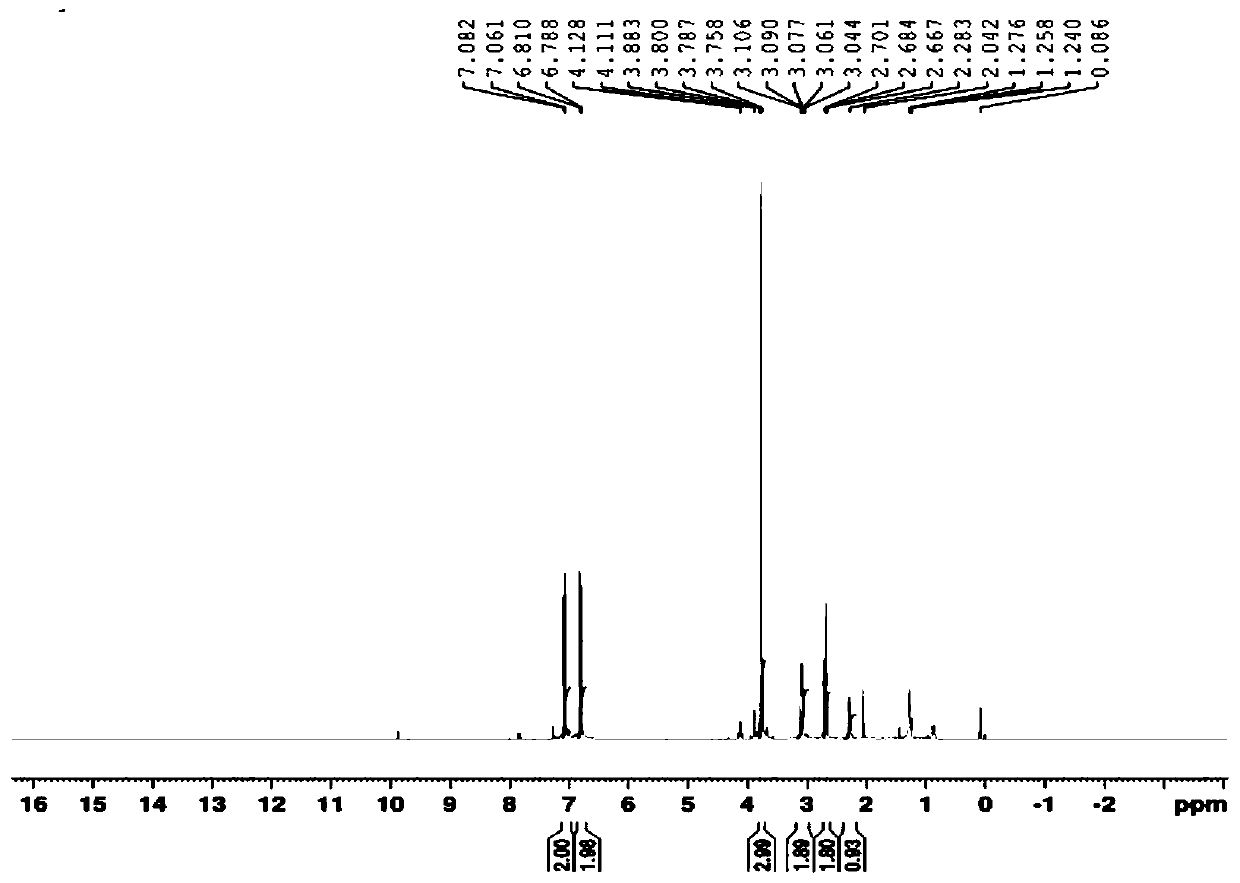

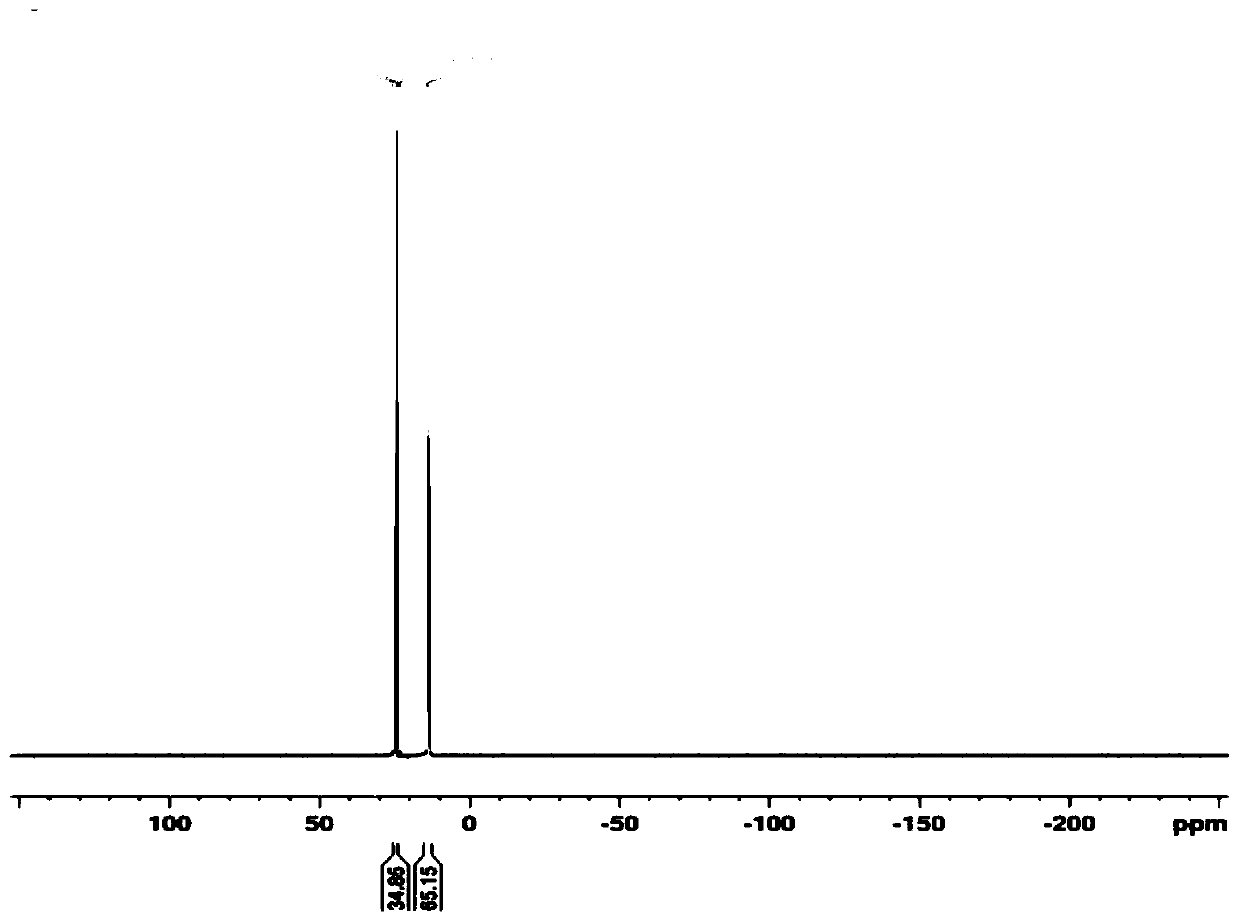

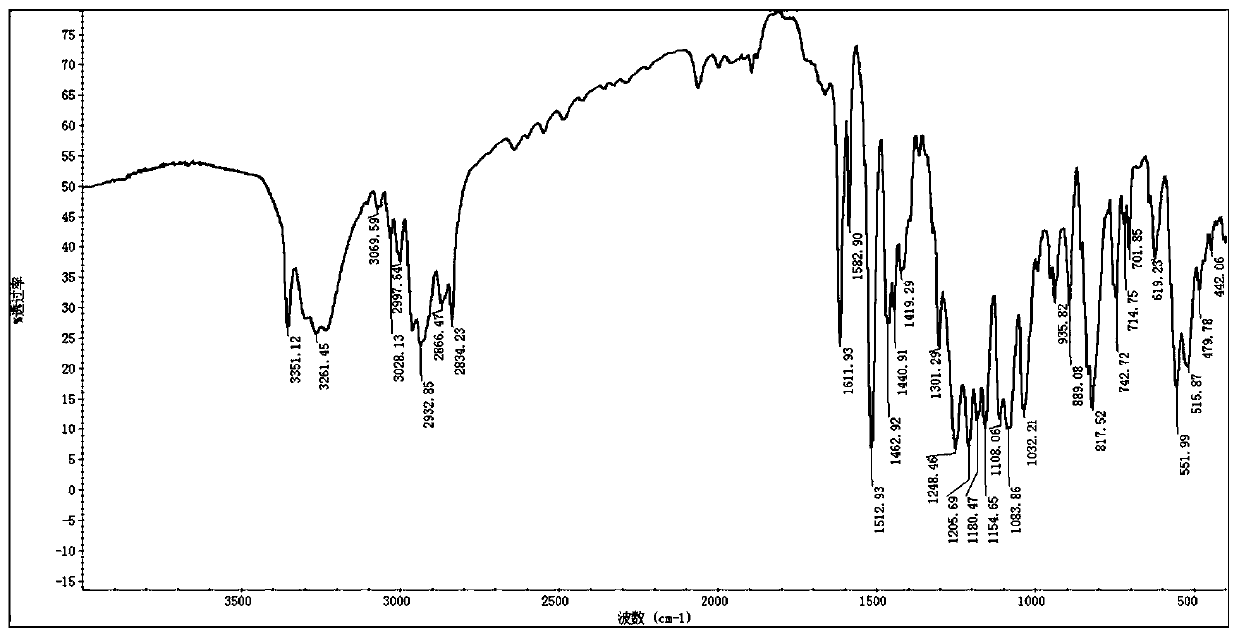

Application and preparation method of hexa(4-methoxyphenylethylamino) cyclotriphosphazene flame retardant

A technology of methoxyphenethylamine and methoxyphenethylamine, which is applied in the field of novel nitrogen and phosphorus-based additive flame retardants, and can solve problems such as being difficult to decompose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take a dry 500ml three-necked bottle, replace it with nitrogen three times, add 12.3g of potassium carbonate to it, stir and add 100ml of THF, slowly add 50ml of THF solution containing 27g of p-methoxyphenylethylamine dropwise, and heat up after the dropwise addition To 45°C, add dropwise 10g of hexachlorocyclotriphosphazene in 50ml THF solution at 40-50°C, heat up to 68°C after the dropwise addition, and monitor the end point of the reaction by thin-layer chromatography. Concentrate under low pressure to obtain a viscous yellow solid, which is washed with water, ethanol, and n-hexane in turn, and finally crystallized in n-hexane to obtain 3.04 g of a yellow solid, with a yield of 61.29%.

Embodiment 2

[0029] Take a dry 500ml three-necked bottle, replace it with nitrogen three times, add 12.3g of potassium carbonate to it, stir and add 100ml of THF, slowly add 50ml of THF solution containing 27g of p-methoxyphenylethylamine dropwise, and heat up after the dropwise addition To 45°C, add dropwise 10g of hexachlorocyclotriphosphazene in 50ml THF solution at 40-50°C, heat up to 68°C after the dropwise addition, and monitor the end point of the reaction by thin-layer chromatography. Concentrate under low pressure to obtain a viscous yellow solid, which is washed with water, ethanol, and n-hexane in turn, and finally column chromatography gives 2.31 g of a yellow solid with a yield of 46.57%.

Embodiment 3

[0031] Take a dry 500ml three-necked bottle, replace it with nitrogen three times, add 7.14g of sodium hydroxide to it, stir and add 50ml of MCB, after stirring evenly, slowly add 100ml of 30.45g of p-methoxyphenethylamine MCB solution, warm up to 45°C after the dropwise addition, add dropwise 50ml MCB solution of 10g hexachlorocyclotriphosphazene at 40-50°C, raise the temperature to 100°C after the dropwise addition, monitor the end point of the reaction by thin-layer chromatography, after the end of the reaction , filtered with suction, and the filtrate was concentrated under vacuum to obtain a viscous yellow solid, which was washed with water, ethanol, and n-hexane in turn, and finally crystallized in n-hexane to obtain 1.97 g of a yellow solid, with a yield of 39.72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com