Ultra-low-VOC high-solid-content waterborne epoxy coating and preparation method and application thereof

An epoxy coating, water-based technology, applied in the field of coating materials, can solve the problems of long manufacturing cycle, long cycle, cumbersome process, etc., and achieve the effect of reducing VOC emissions and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 waterborne epoxy resin

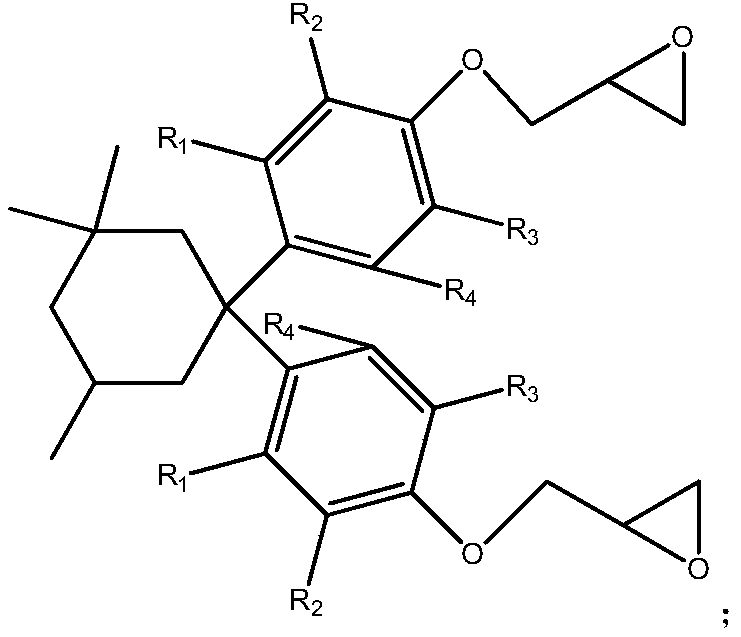

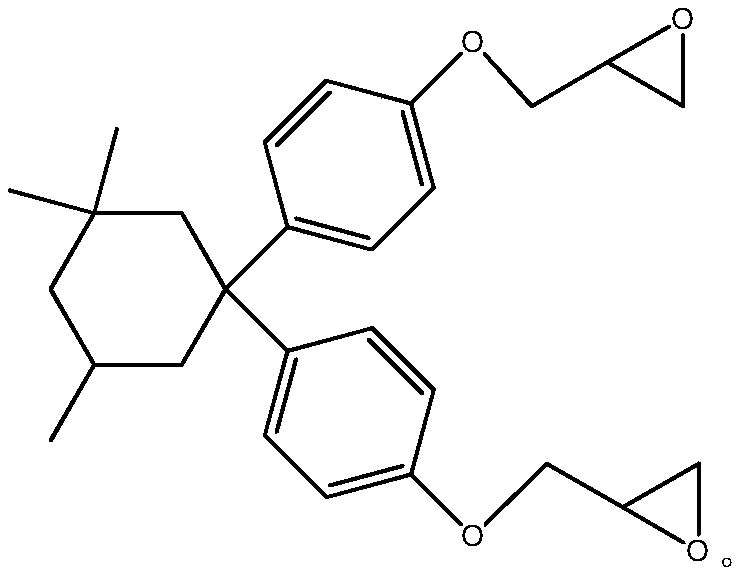

[0026] The compound shown in formula I and epichlorohydrin are stirred and heated, and when the temperature rises to 60-70°C, sodium hydroxide aqueous solution is added dropwise, and the dropwise addition is completed within 2 hours at 70-80°C; Keep at 90-100°C for 1-2 hours to obtain a viscous resin; add distilled water and toluene to the viscous resin, stir to dissolve the resin, remove the water layer by static layering, and evaporate the toluene layer to dryness under reduced pressure to obtain; The molar ratio of the compound to epichlorohydrin is n: (2n+2 to 2n+4); the content of sodium hydroxide in the aqueous sodium hydroxide solution is 0.5n-1.5n moles; the volume ratio of distilled water and toluene is 1:2 .

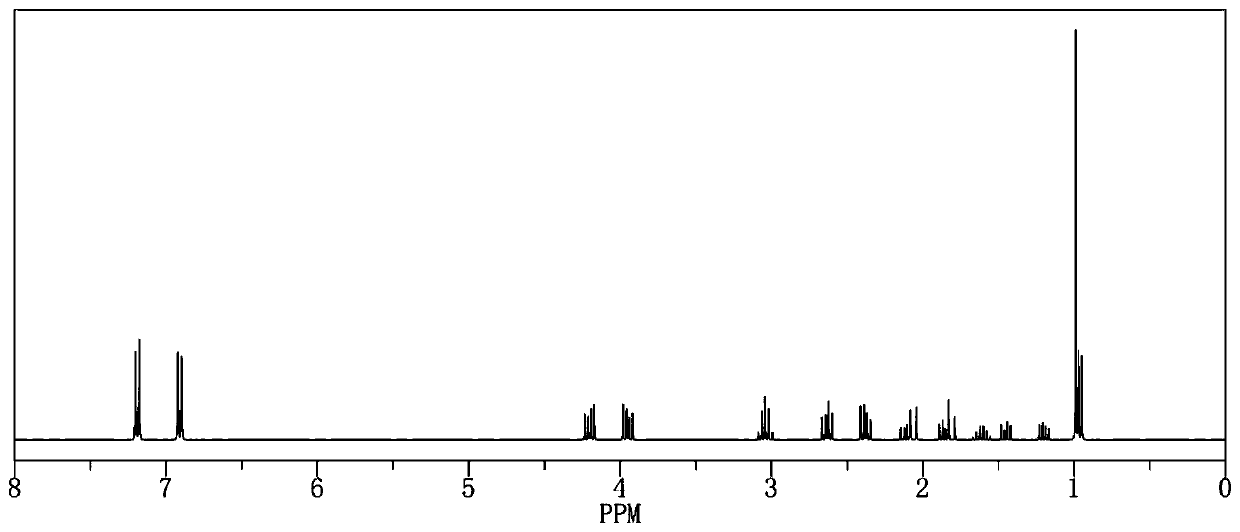

[0027] 408g of the reaction product was obtained, m / z=422.2, see figure 1 .

Embodiment 2

[0028] The preparation of embodiment 2 waterborne epoxy resins

[0029] The compound shown in formula I and epichlorohydrin are stirred and heated, and when the temperature rises to 60-70°C, sodium hydroxide aqueous solution is added dropwise, and the dropwise addition is completed within 2 hours at 70-80°C; Keep at 90-100°C for 1-2 hours to obtain a viscous resin; add distilled water and toluene to the viscous resin, stir to dissolve the resin, remove the water layer by static layering, and evaporate the toluene layer to dryness under reduced pressure to obtain; The molar ratio of the compound to epichlorohydrin is n: (2n+2 to 2n+4); the content of sodium hydroxide in the aqueous sodium hydroxide solution is 0.5n-1.5n moles; the volume ratio of distilled water and toluene is 1:2 .

[0030] 395g of the reaction product was obtained, m / z=422.2, see figure 1 .

Embodiment 3

[0031] The preparation of embodiment 3 waterborne epoxy resins

[0032] The compound shown in formula I and epichlorohydrin are stirred and heated, and when the temperature rises to 60-70°C, sodium hydroxide aqueous solution is added dropwise, and the dropwise addition is completed within 2 hours at 70-80°C; Keep at 90-100°C for 1-2 hours to obtain a viscous resin; add distilled water and toluene to the viscous resin, stir to dissolve the resin, remove the water layer by static layering, and evaporate the toluene layer to dryness under reduced pressure to obtain; The molar ratio of the compound to epichlorohydrin is n: (2n+2 to 2n+4); the content of sodium hydroxide in the aqueous sodium hydroxide solution is 0.5n-1.5n moles; the volume ratio of distilled water and toluene is 1:2 .

[0033] 392g of the reaction product was obtained, m / z=422.2, see figure 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap