Steel plate for electric rice cooker shell, preparation method thereof, and chrome-plated plate

A technology of electric cooker and steel plate, applied in the field of steel rolling, can solve the problems of ridges, large fluctuation range of hardness, curved surface of slip line texture, etc., and achieves the effects of high performance stability, strong aging resistance and high formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the preparation method of the steel plate and the chrome-plated plate used for the shell of the electric cooker of the present application, the effects of each process are as follows:

[0037] Steelmaking: The molten steel is subjected to RH refining vacuum degassing treatment, and corresponding measures to control inclusions are adopted, and finally the continuous casting slab is produced by the conventional continuous casting process, and then hot rolled.

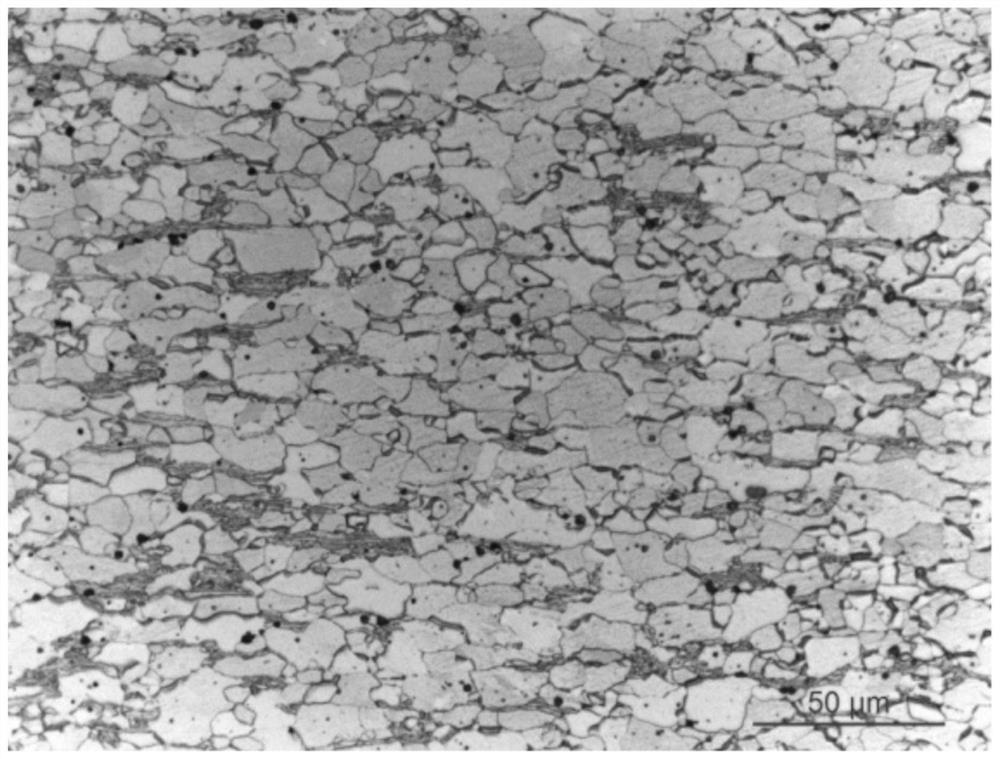

[0038] Hot rolling: the method of the present invention adopts austenitic rolling + low-temperature coiling process in the hot rolling process, and the temperature of the slab out of the furnace is controlled between 1200-1280 °C, in order to avoid mixed crystals in the strip during low-temperature two-phase rolling Microstructure, using a higher finish rolling temperature, the finish rolling temperature is controlled at 880±20°C, in order to suppress the precipitation and coarsening of AlN, the coiling temperatu...

Embodiment 1

[0046] The Ti-IF steel was used, the molten steel was refined by RH, and the continuous casting slab was produced by the conventional continuous casting process. The chemical composition of the molten steel is shown in Table 1.

[0047] Table 1 Substrate Chemical Composition Performance of Example 1, Wt%

[0048] C(%) Si(%) Mn(%) P(%) S(%) Alt(%) 0(%) N(%) 0.04 0.01 0.24 0.006 0.007 0.047 0.0002 0.0021

[0049] The continuous casting slab is heated, rough rolled, finish rolled, layer cooled and coiled before hot rolling to produce cold rolled sheet through pickling + cold continuous rolling unit. The specific process parameters are shown in Table 2.

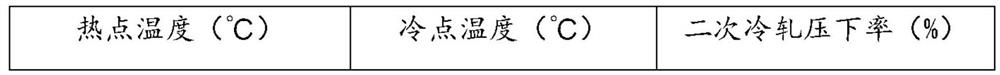

[0050] Table 2 Example 1 main rolling process parameters and actual performance

[0051] Tapping temperature (℃) Finishing temperature (℃) Coiling temperature (℃) Primary cold rolling reduction (%) 1280 879 570 86

[0052] The cold-rolled steel strip is recrystallized...

Embodiment 2

[0061] The Ti-IF steel was used, the molten steel was refined by RH, and the continuous casting slab was produced by the conventional continuous casting process. The chemical composition of the molten steel is shown in Table 5.

[0062] Table 5 Example 2 Substrate Chemical Composition Performance, Wt%

[0063] C(%) Si(%) Mn(%) P(%) S(%) Alt(%) 0(%) N(%) 0.04 0.01 0.24 0.01 0.007 0.046 0.0002 0.0023

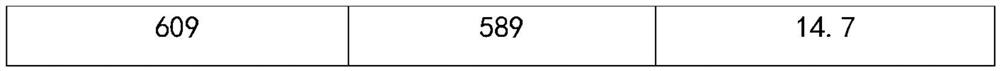

[0064] The continuous casting slab is heated, rough rolled, finish rolled, layer cooled and coiled before hot rolling to produce cold rolled sheet through pickling + cold rolling unit. The specific process parameters are shown in Table 6.

[0065] Table 6 Example 2 main rolling process parameters and actual performance

[0066] Tapping temperature (℃) Finishing temperature (℃) Coiling temperature (℃) Primary cold rolling reduction (%) 1280 881 571 85

[0067] The cold-rolled steel strip is recrystallized and annealed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com