Chemical vapor deposition monitoring system and method

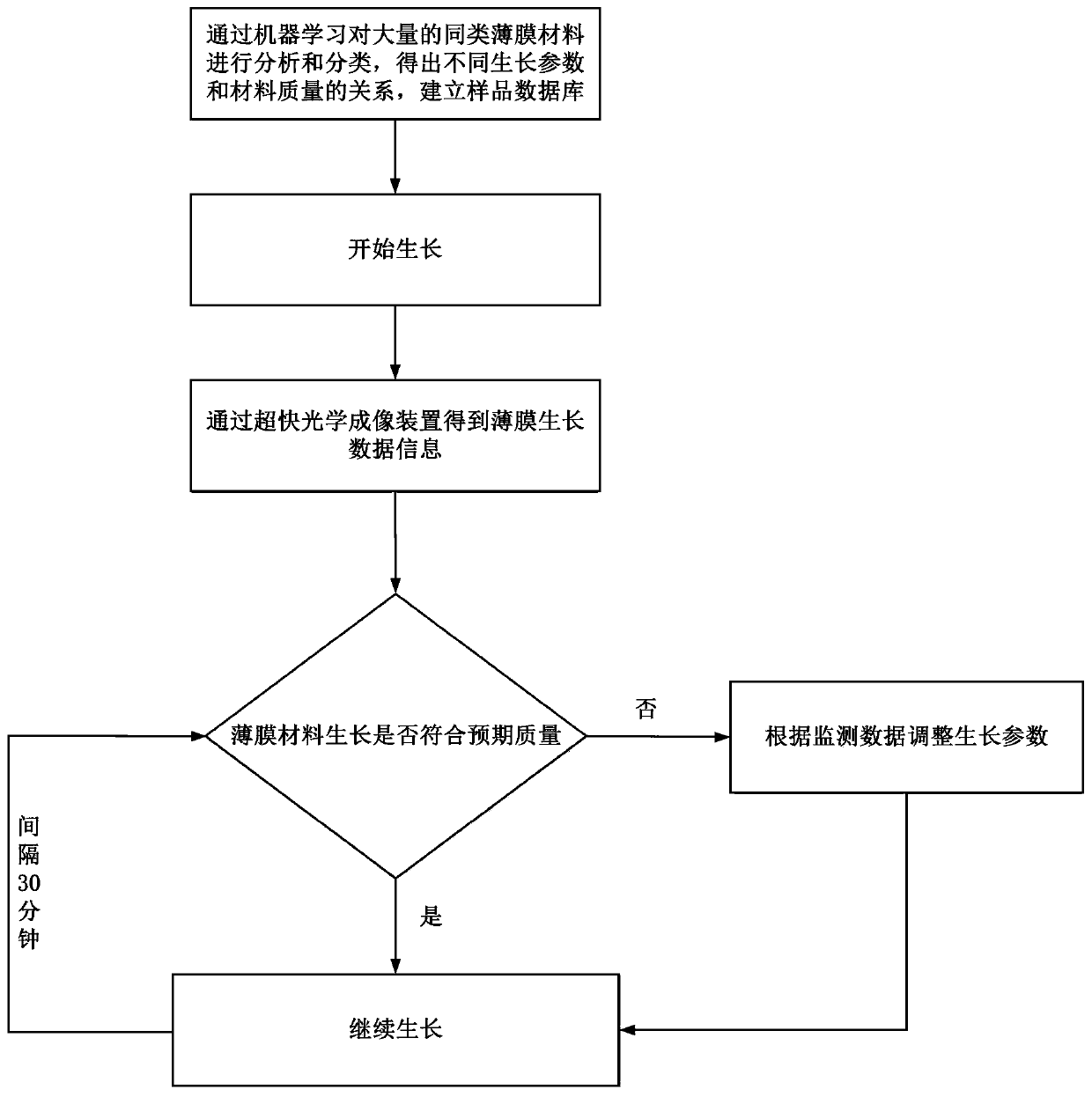

A technology of chemical vapor deposition and monitoring system, which is applied in the field of film growth monitoring, can solve the problems that the film growth status cannot be monitored quickly and in real time, and achieve the effect of facilitating system implementation and improving growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

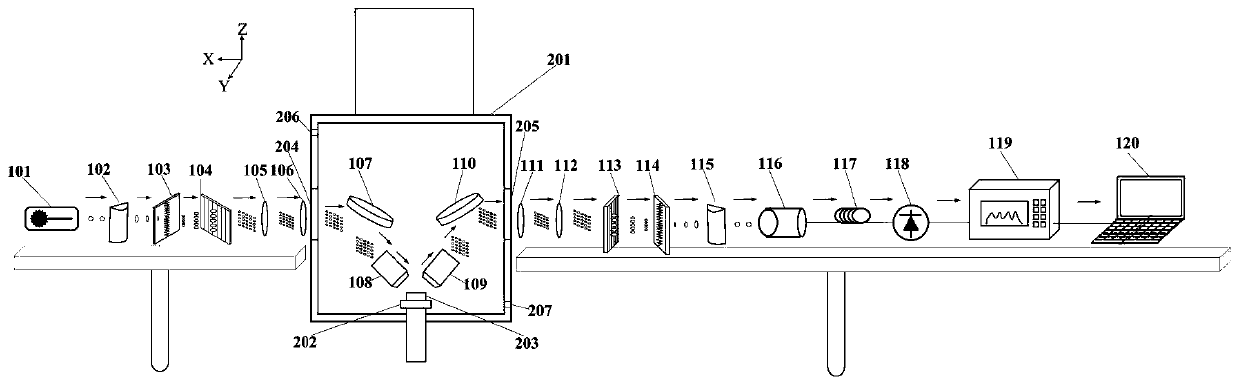

[0035] The invention provides a chemical vapor deposition monitoring system, comprising: a chemical vapor deposition device and an optical imaging detection device. The thin film material to be monitored is placed in the chemical vapor deposition device; the optical imaging detection device includes: a femtosecond pulsed laser, a first cylindrical lens, a first virtual imaging phase array, a first diffraction grating, a focusing component, a pulse A reduction component, a single-mode optical fiber, a photodetector, and a high-speed oscilloscope; the focusing component includes a first microscope objective lens; the pulse reduction component includes a second microscope objective lens, a second diffraction grating, a second virtual imaging phase array, and a second Two cylindrical lenses.

[0036] The femtosecond pulse laser is used to generate a femtosecond pulse; the first cylindrical lens is used to compress the femtosecond pulse into a linear pulse; the first virtual imagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com