Customized fixed denture processing method

A processing method and technology for fixing dentures, applied in dentures and other directions, can solve problems such as affecting the patient's use effect, insufficient bonding force, and porcelain stretching, and achieve the effects of increasing adhesion, increasing water properties, and high similarity of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

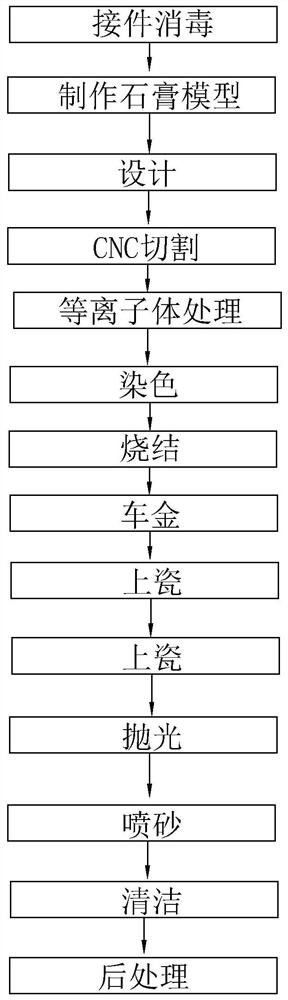

[0045] A custom-made fixed denture processing method, comprising the following processing steps:

[0046] Step 1: Sterilize the parts, accept the original dental model from the dentist, conduct disinfection inspection on the dental model, and proceed to the next step after passing the inspection, and submit unqualified products to the dentist for re-modeling; the specific disinfection process can be applied to disinfection soaking method and ultraviolet irradiation method , Model disinfection and sterilization machine or the method of adding medicine in gypsum to eliminate bloodstains, saliva and bacteria etc. on gypsum, adopt disinfection soaking method in the present embodiment, specifically put the original denture into 0.5% 84 disinfectant and soak for 20min; The inspection is usually to check whether the incoming model is intact, whether the impression is clear, etc., put the inspected model in the qualified area, the area to be judged, the area to be inspected, and the un...

Embodiment 2

[0064] The difference between Example 2 and Example 1 lies in the different sintering parameters in step 7. Specifically, the sintering temperature of the first stage is 1100°C, the sintering time is 28min, the temperature of the second stage is 1550°C, and the sintering time is 1.5h .

Embodiment 3

[0066] The difference between Example 3 and Example 1 lies in the different sintering parameters in step 7. Specifically, the sintering temperature of the first stage is 1150° C., the sintering time is 30 minutes, and the temperature of the second stage is 1500° C., and the sintering time is 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com