Reduction curing and stabilizing method for arsenic sulfide slag

A technology of arsenic sulfide and hydrogen chloride, which is applied in the direction of protection devices against harmful chemicals, and can solve problems such as complex process operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

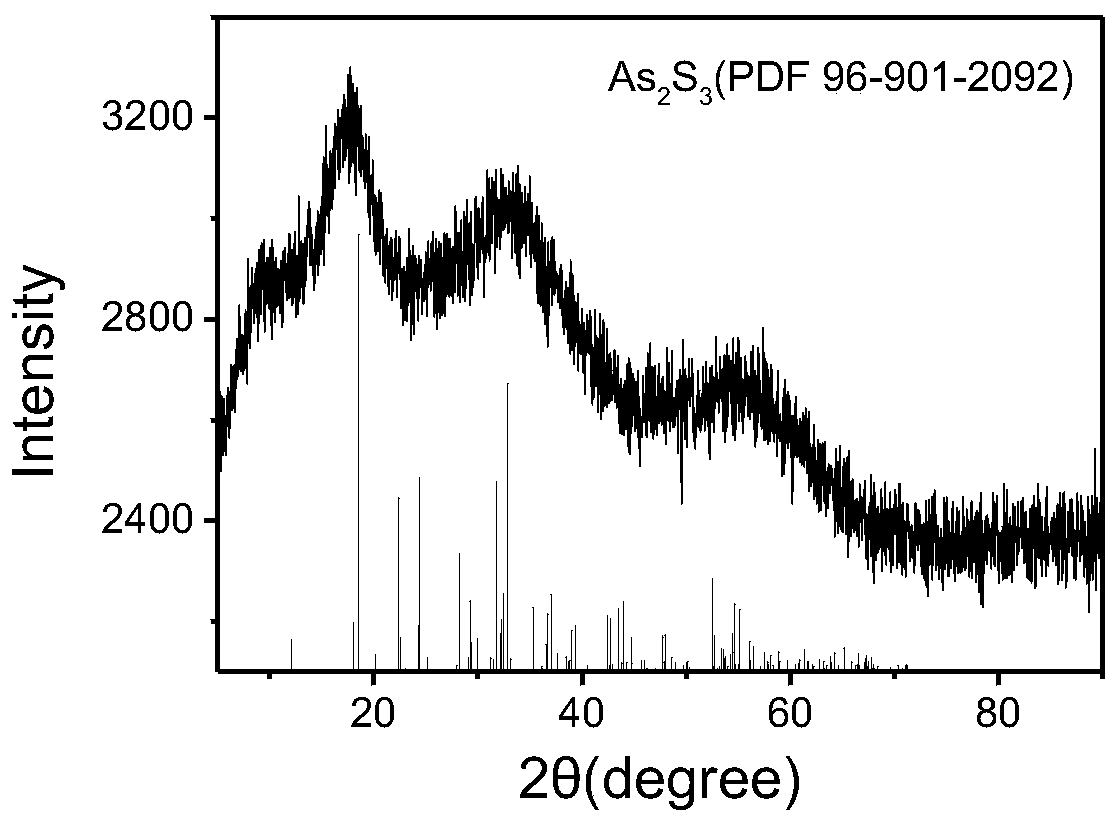

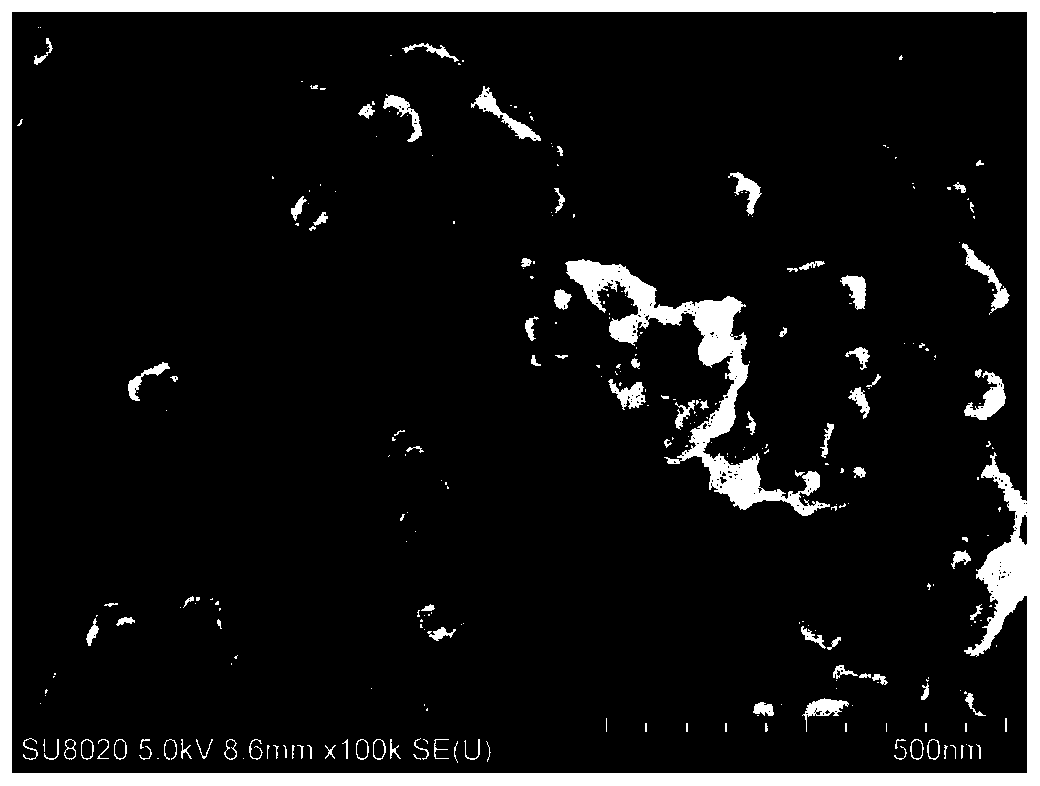

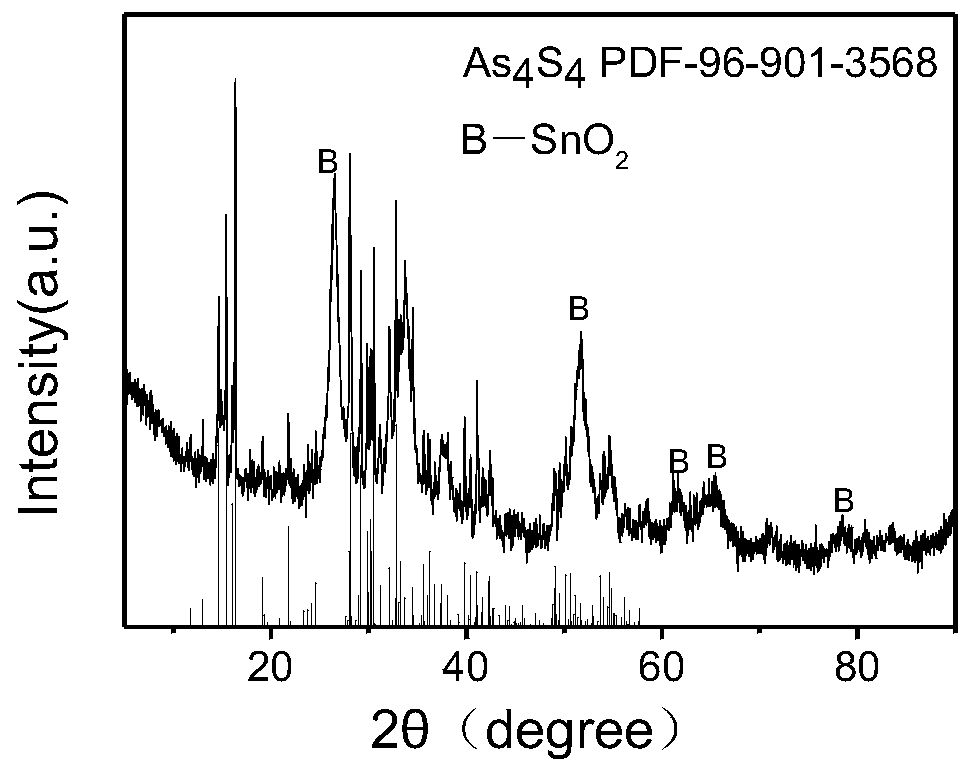

Image

Examples

Embodiment example 1

[0021] The specific operation steps are as follows:

[0022] Take 0.1g of simulated arsenic sulfide slag and add it to the reaction kettle, add 0.1mol / L stannous chloride dihydrate solution to make the solid-liquid ratio 1:150g / ml, adjust the pH value to 1, stir well, and put the reaction The kettle was put into reaction at 200°C for 10 hours, cooled naturally to room temperature, washed, filtered and dried to obtain an arsenic-containing solid. After hydrothermal treatment, the residual arsenic concentration in the solution is below 5 mg / L, the arsenic fixation rate reaches 99.8%, and the toxic leaching of arsenic is 1.8 mg / L.

Embodiment example 2

[0024] Take 0.2g of simulated arsenic sulfide slag and add it to the reaction kettle, add 0.1mol / L stannous chloride dihydrate solution to make the solid-liquid ratio 1:80g / ml, adjust the pH value to 0.5, stir well, and put the reaction The kettle was placed at 200°C for 12 hours, cooled naturally to room temperature, washed, filtered and dried to obtain an arsenic-containing solid. After hydrothermal treatment, the residual arsenic concentration in the solution is below 40mg / L, the arsenic fixation rate reaches 99.5%, and the toxic leaching of arsenic is 3.8mg / L.

Embodiment example 3

[0026] Take 0.15g of simulated arsenic sulfide slag and add it to the reaction kettle, add 0.2mol / L stannous chloride dihydrate solution to make the solid-liquid ratio 1:100g / ml, adjust the pH value to 0.8, stir well, and put the reaction The kettle was placed at 200°C for 12 hours, cooled naturally to room temperature, washed, filtered and dried to obtain an arsenic-containing solid. After hydrothermal treatment, the residual arsenic concentration in the solution is below 10 mg / L, the arsenic fixation rate reaches 99.8%, and the toxic leaching of arsenic is 2.0 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com