Automatic punching production line for cylindrical battery steel shell

An automated production line, cylindrical battery technology, applied in the direction of cylindrical shell battery/battery, battery pack parts, secondary battery manufacturing, etc., can solve the problems that steel strip materials cannot be used, failures occur, and the utilization rate of materials can no longer be improved. , to achieve the effect of reducing punch failures and product quality problems, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution will be further explained with the example of AA battery steel case and accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit its scope of application. Similar implementations can be applied to cylindrical battery steel cases Such as AAA, 18650, 21700 and other more models.

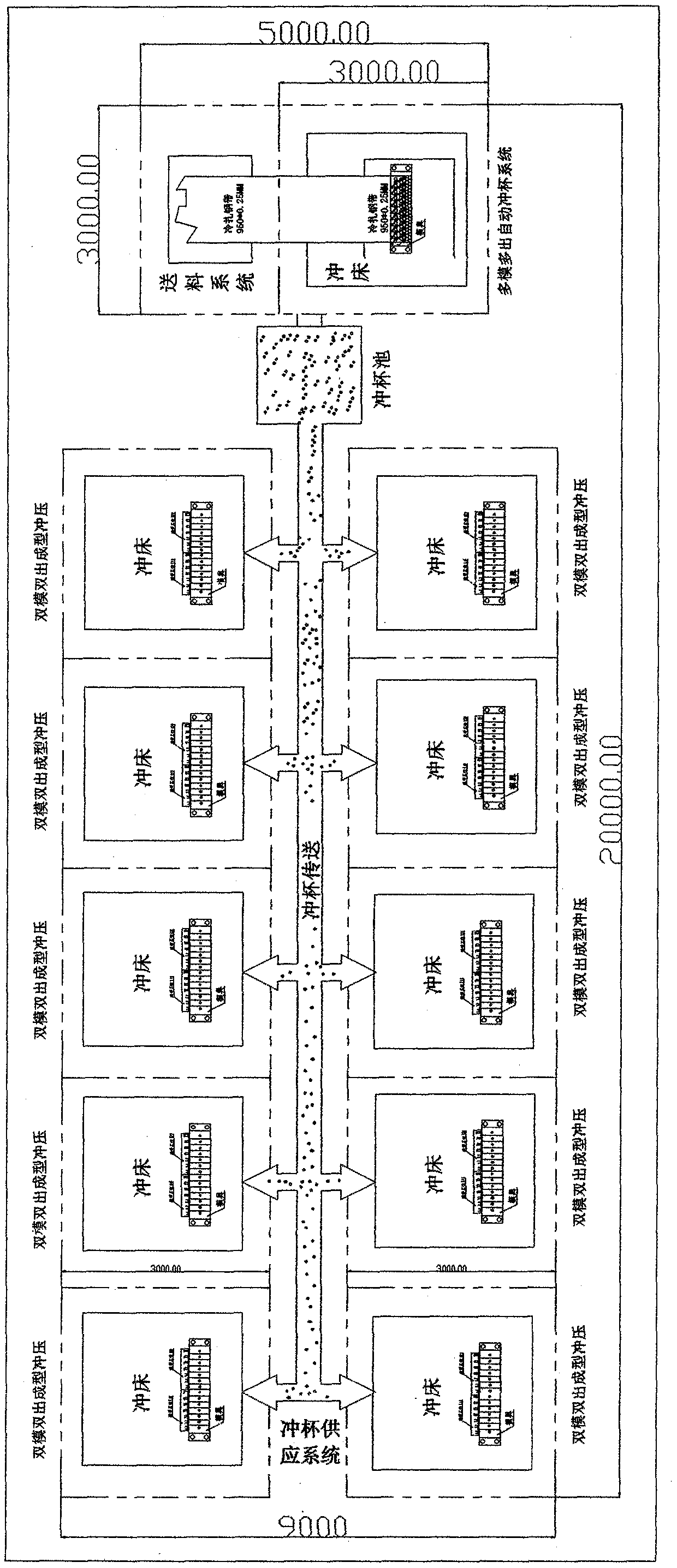

[0024] image 3 , Multi-mode multi-outlet automatic cupping system, referred to as the central cupping system, includes a multi-mode multi-outlet blanking cupping device and a feeding system.

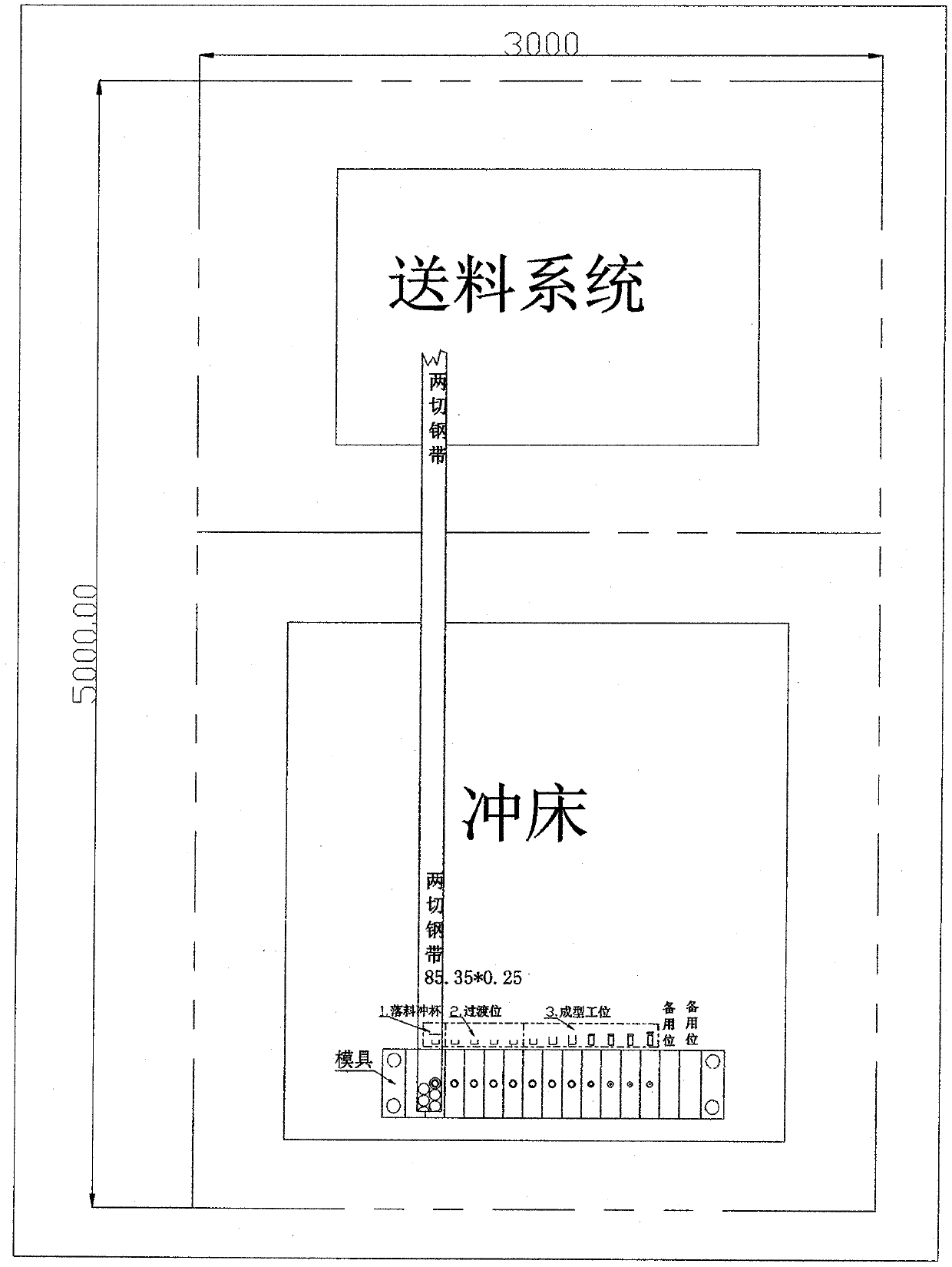

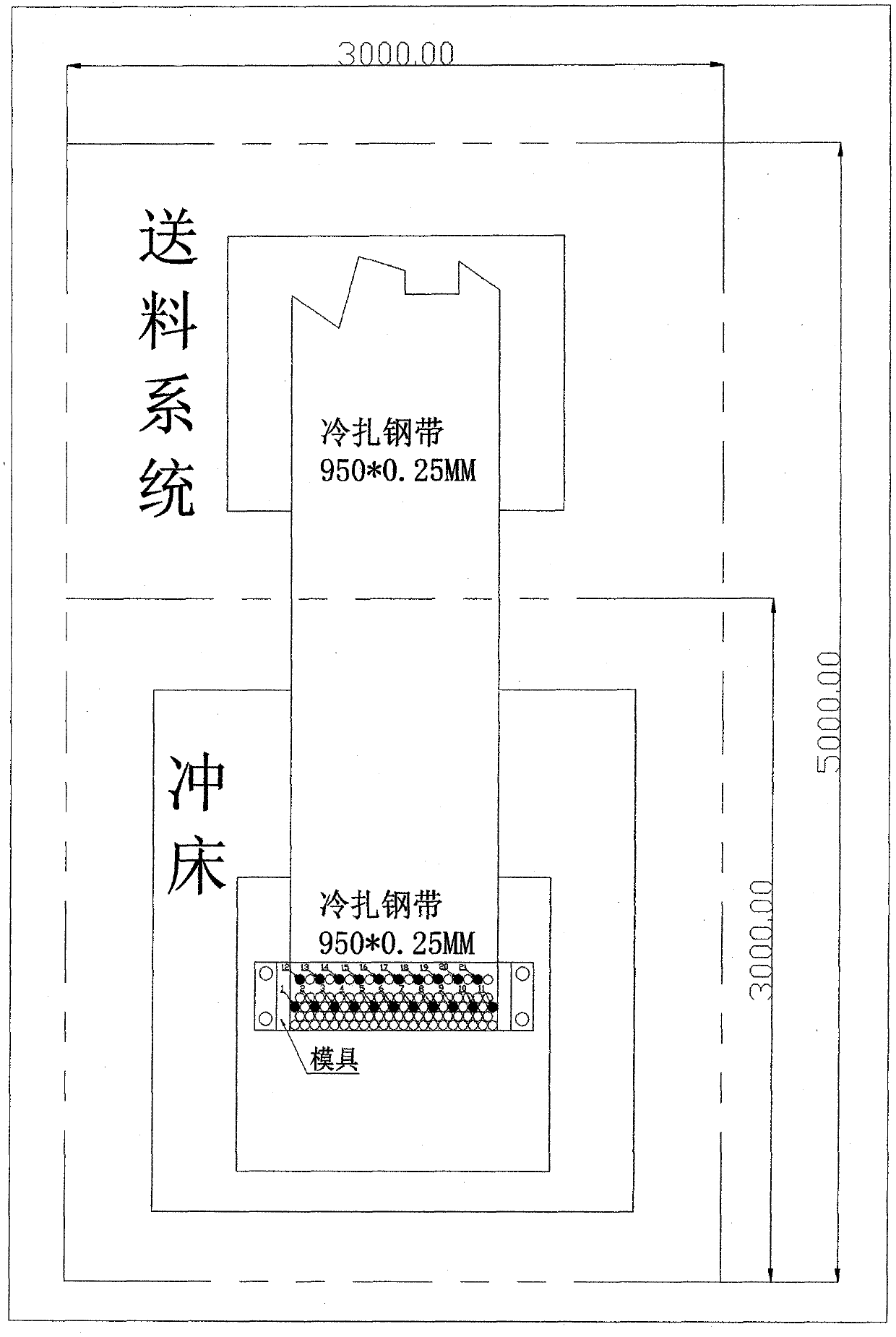

[0025] 1) Figure 4 , 21 Cut blanking and punching cup process mold layout: Take AA battery steel shell as an example, set the blanking diameter to 44.2mm, and take the minimum value of each edge as 1mm. Use the cold-rolled steel strip width of 950mm, assuming that the largest can be arranged along the width direction The number of blanking holes is n, then (44.2+1)n+1=950, and n=21, then the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com