Production method for basalt fibers by adopting modified basalt

A technology of basalt fiber and basalt, which is applied in the field of producing basalt fiber by using modified basalt, can solve the problems of reducing production cost, increasing production cost, dust pollution, etc., and achieves the effect of reducing production cost and stabilizing the production of basalt fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

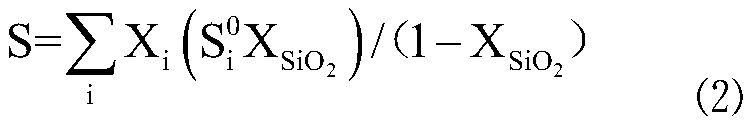

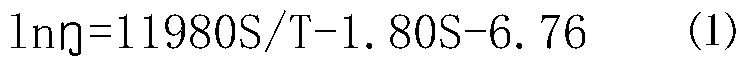

Method used

Image

Examples

Embodiment 1

[0031] A method for producing basalt fibers using modified basalt, comprising the following steps in sequence:

[0032] 1) remove impurities in the basalt by screening;

[0033] 2) drying the basalt after screening in step 1);

[0034] 3) crushing the dried basalt in step 2) to obtain basalt particles;

[0035] 4) Mix the basalt particles obtained after crushing in step 3), ingredients for modifying the basalt particles and sodium silicate powder, the ingredients being one of quartz sand particles, zircon sand particles and yttrium oxide powder species, two or more;

[0036] 5) adding water to the mixed material obtained after mixing in step 4), the sodium silicate powder is dissolved in water to form water glass, and then stirred, and the wet mixed material is obtained after stirring evenly;

[0037] 6) then the wet mixture obtained in step 5) is dried, and the dry mixture is obtained after the drying is completed. After the drying is completed, the ingredients are adhered...

Embodiment 2

[0041] Embodiment 2, on the basis of the above-mentioned embodiment 1, further preferably, in step 1), the basalt includes the following components in mass percentage: 14% to 17% Al 2 o 3 , 4% to 7% Fe 2 o 3 , 6%~8% FeO, 5%~8% MgO, 2%~9% CaO, 0.8%~2.5% TiO 2 , 1% ~ 3.5% Na 2 O, 2% ~ 4% K 2 O, the balance is SiO 2 and unavoidable impurities.

Embodiment 3

[0042]Embodiment 3, on the basis of the above embodiment 1, further preferably, in step 2), the drying treatment is to keep the screened basalt at 100°C-110°C for 16h-20h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com