Phosphorus-containing flame retardant and preparation method

A flame retardant and solvent technology, applied in the field of phosphorus-containing flame retardants and preparation, can solve problems such as complicated preparation, and achieve the effect of strengthening the flame retardant effect and enriching the flame retardant methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

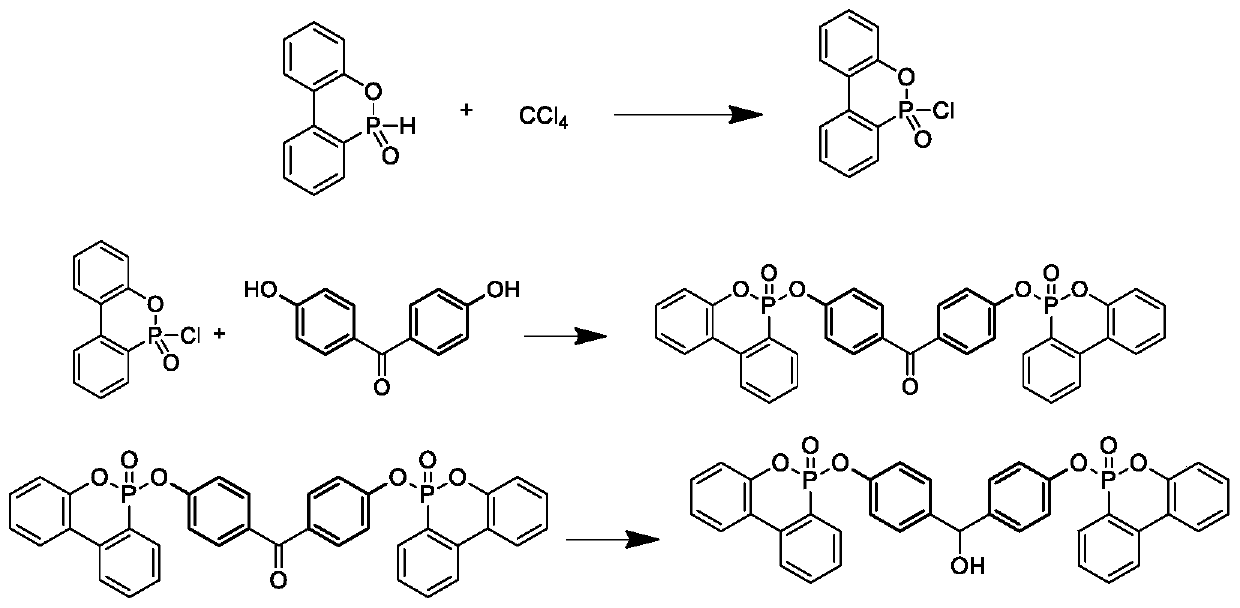

Method used

Image

Examples

Embodiment 1

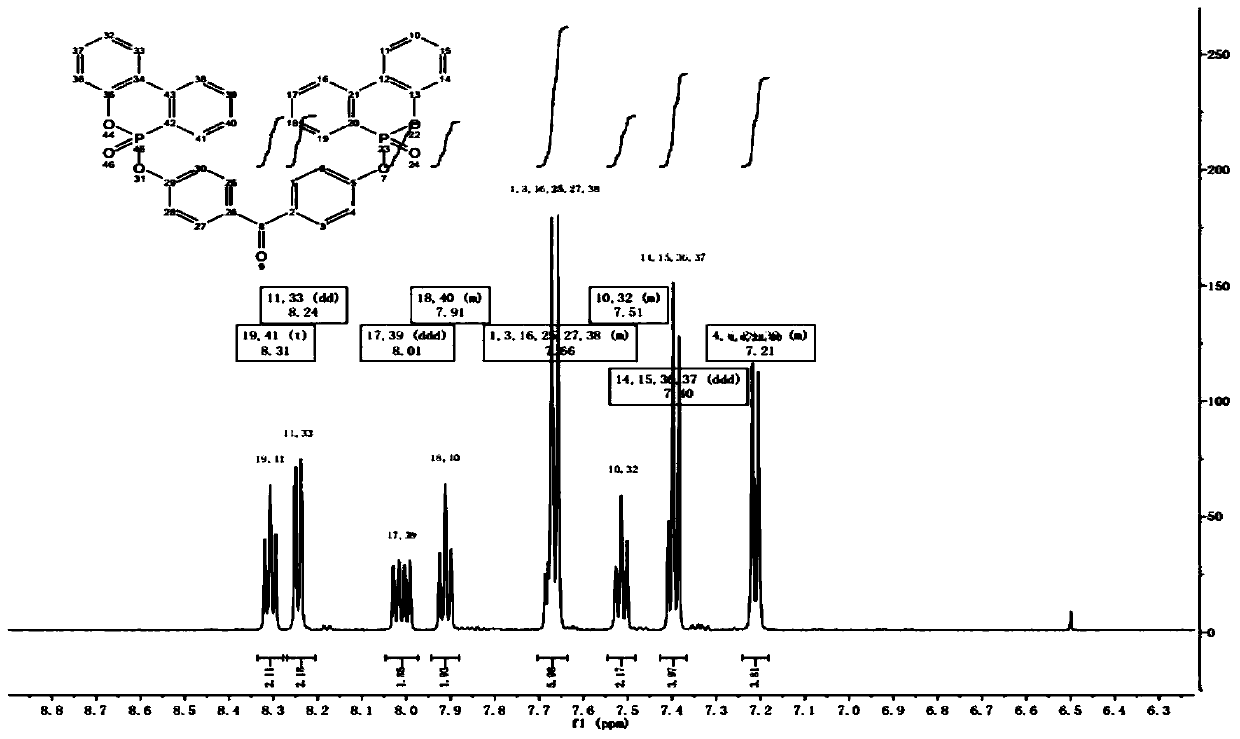

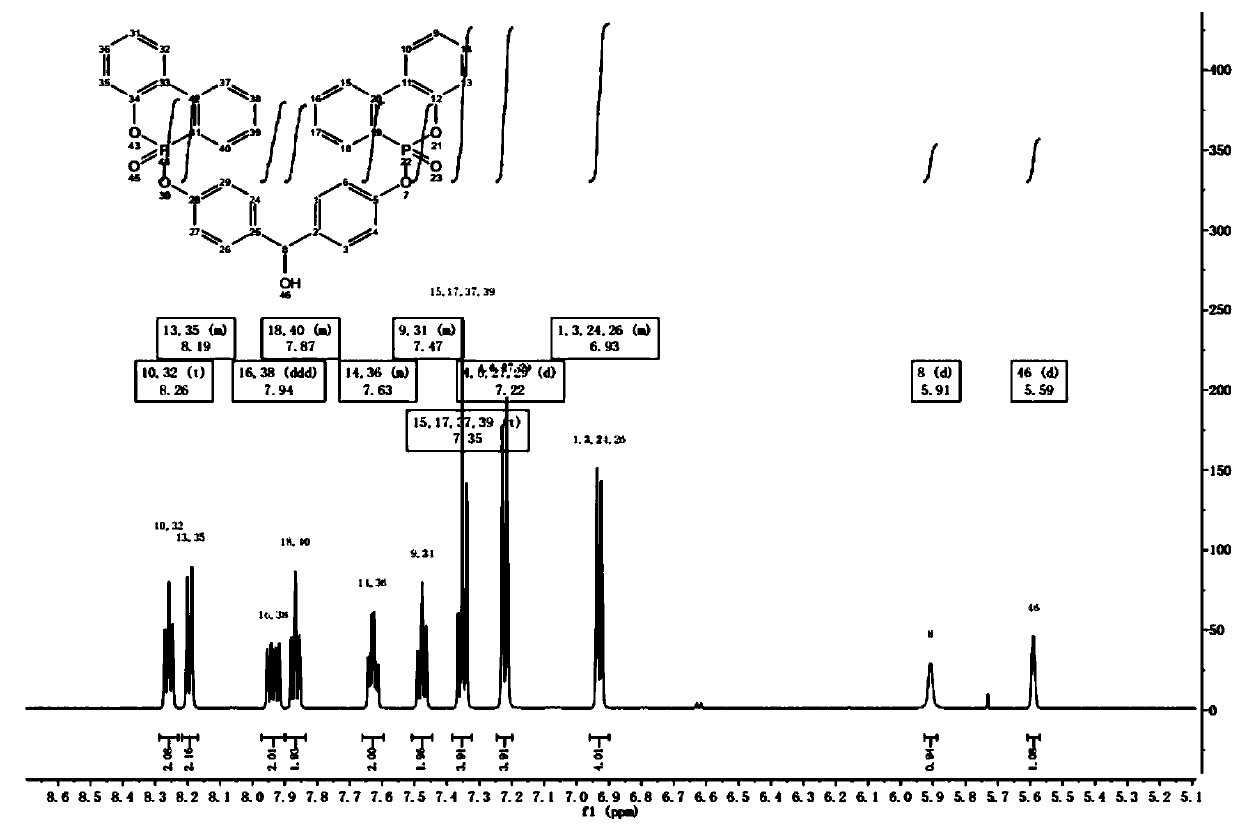

[0029] Add 1.0mol 4,4'-dihydroxybenzophenone (DHBP), dichloromethane, and 3.0mol triethylamine into a reaction vessel equipped with stirring, heating, and temperature control devices; stir for 30 minutes under nitrogen protection Add 2.0mol 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and 2.0mol carbon tetrachloride (CCl 4 ), stirring and reacting at 25°C for 1h after the addition was completed, adding water to quench the reaction, extracting 3 times with dichloromethane, washing the organic phase 3 times with deionized water, evaporating the dichloromethane to dryness under reduced pressure to obtain a white solid, which was purified by column chromatography The product was separated and purified to obtain 4,4'-bis(diphenoxyphosphor-6-oxyl)benzophenone (DODH). Then add 1.0mol DODH, tetrahydrofuran, 1.0mol NaBH into the reaction vessel equipped with stirring, heating and temperature control devices 4 ; Stir at 25°C for 4h after the addition, evaporate the solvent...

Embodiment 2

[0031] Add 1.0mol 4,4'-dihydroxybenzophenone (DHBP), dichloromethane, and 4.6mol triethylamine into a reaction vessel equipped with stirring, heating, and temperature control devices; stir for 30 minutes under nitrogen protection Add 2.3mol 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and 3.0mol carbon tetrachloride (CCl 4 ), stirring and reacting at 25°C for 1h after the addition was completed, adding water to quench the reaction, extracting 3 times with dichloromethane, washing the organic phase 3 times with deionized water, evaporating the dichloromethane to dryness under reduced pressure to obtain a white solid, which was purified by column chromatography The product was separated and purified to obtain 4,4'-bis(diphenoxyphosphor-6-oxyl)benzophenone (DODH). Then add 1.0mol DODH, tetrahydrofuran, 1.3mol NaBH into the reaction vessel equipped with stirring, heating and temperature control devices 4 ; Stir at 25°C for 4h after the addition, evaporate the solvent...

Embodiment 3

[0033] Add 1.0mol 4,4'-dihydroxybenzophenone (DHBP), dichloromethane, and 3.76mol triethylamine into a reaction vessel equipped with stirring, heating, and temperature control devices; stir for 30 minutes under nitrogen protection Add 2.15mol 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and 2.47mol carbon tetrachloride (CCl 4 ), stirring and reacting at 25°C for 1h after the addition was completed, adding water to quench the reaction, extracting 3 times with dichloromethane, washing the organic phase 3 times with deionized water, evaporating the dichloromethane to dryness under reduced pressure to obtain a white solid, which was purified by column chromatography The product was separated and purified to obtain 4,4'-bis(diphenoxyphosphor-6-oxyl)benzophenone (DODH). Then add 1.0mol DODH, tetrahydrofuran, 1.15mol NaBH into the reaction vessel equipped with stirring, heating and temperature control devices 4 ; Stir at 25°C for 4h after the addition, evaporate the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com