Waste straw energy source, raw material and fertilizer co-production technology and biomass thermoelectric base three-phase clean cogeneration device thereof

A technology for waste straw and biomass, which is used in the removal of solid waste, biofuels, waste fuels, etc., and can solve the problems of lack of space, large occupation, and increased investment in the industrial chain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation

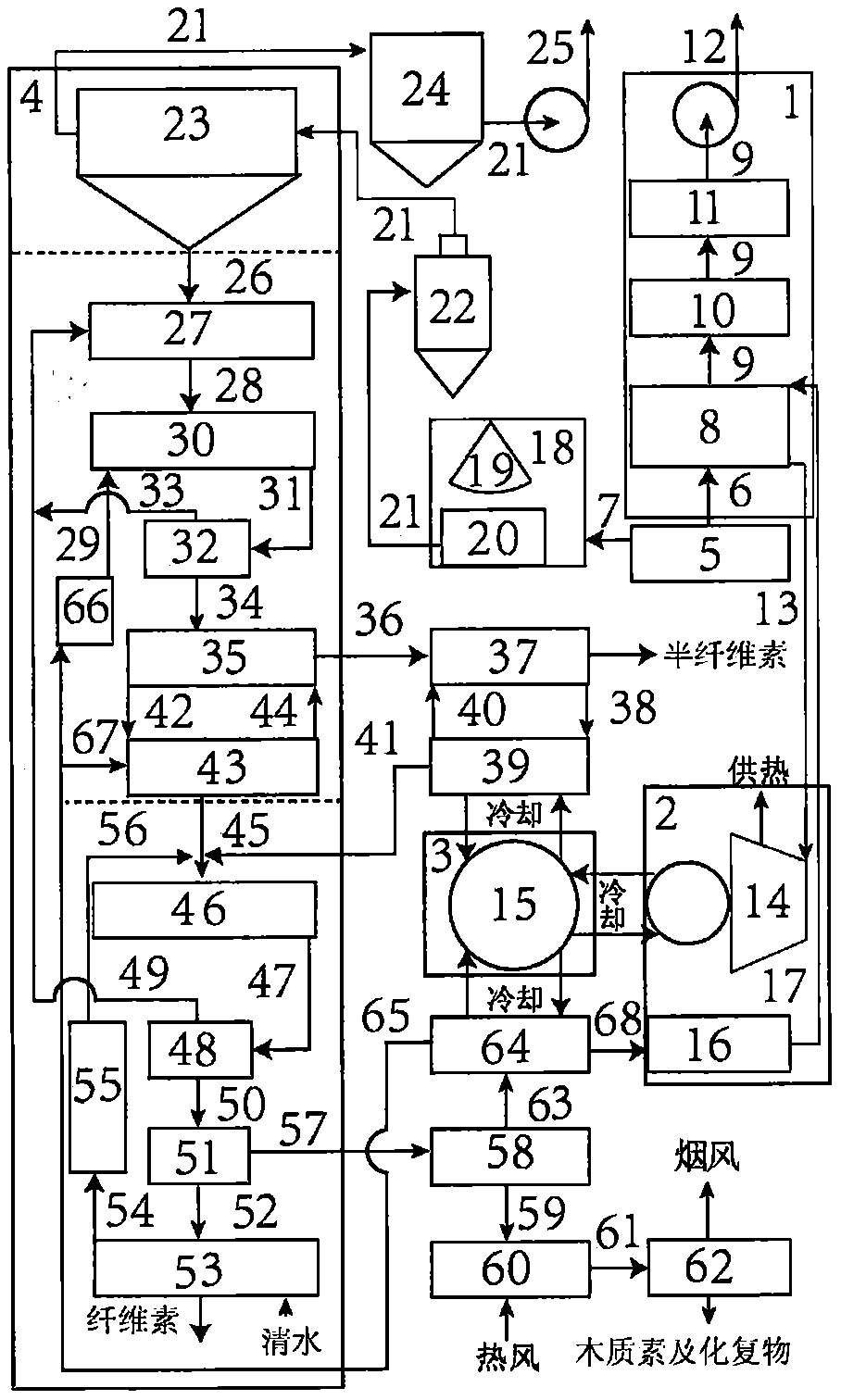

[0030] Attached below figure 1 The present invention is further analyzed.

[0031] like figure 1 As shown, the co-production technology of waste straw energy, raw materials and fertilizer and its biomass thermoelectric-based three-element clean co-production device of the present invention are specifically implemented as follows:

[0032] The first is the intensive integrated structure of agricultural and forestry waste biomass heat and power cogeneration and the intensive integrated structure of waste straw three-element clean cogeneration. Intensive structure of circulating water cooling device 3. Intensive building of waste straw three-element cleaning and co-production.

[0033] The second is the agricultural and forestry waste biomass storage and classification equipment system. The agricultural and forestry waste biomass storage and classification equipment 5, the agricultural and forestry waste biomass fuel conveyor 6, and the waste s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com