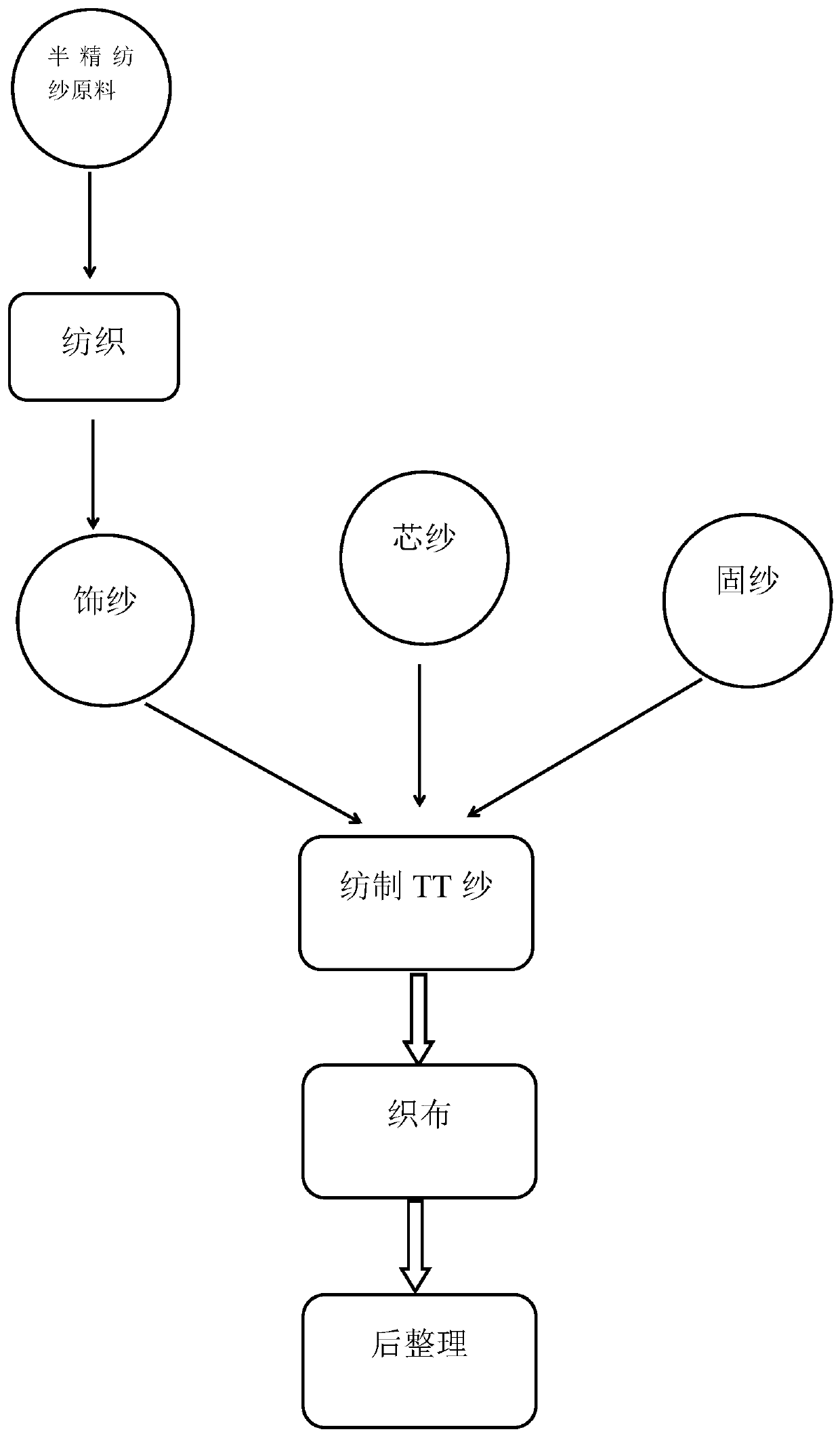

Production and application of novel TT yarn based on semi-worsted yarn as decorative yarn

A technology of semi-worsted spinning and yarn decoration, which is applied in the processing of textile materials, continuous processing of textile materials, yarn and other directions, and can solve the problems of inability to meet the requirements of yarn count for light and thin wool fabrics, inability to process, and short fiber length. , to achieve the effect of improving product competitiveness, soft hand feeling and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] 1. Production of TT yarn:

[0054] S01. Raw material selection: semi-worsted yarn made of 18.5μm 100% woolen top for decorative yarn, and 100D black polyester filament for core thread and anchor thread;

[0055] S02. Semi-worsted decorative yarn spinning: apply wool oil with an oil-water mass ratio of 0.13:1 to the woolen top with a length of 25mm, and make the moisture regain of the woolen top reach 20% after being blended in the woolen warehouse, and then through carding The tops are made into wool tops by combing on the knitting machine and the needle carding machine, and then the tops are drawn in three ways with a draft ratio of 4 times. The wool tops are drafted by a roving frame with a draft ratio of 1.3 times and a spinning frame with a draft ratio of 1.6 times. 1. Twisting with a twist coefficient of 12 times to make spun yarn, and finally doubling and twisting with a twist coefficient of 11 times and a twist of 660 / 420T / to form a final 30Nm / 2 semi-worsted yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com