Unit combined type cesspit structure construction method

A construction method and technology of sewage pool, applied in the direction of structural elements, drainage structures, building components, etc., can solve the problems of difficult control of construction quality, complex structure composition, large capacity, etc., to avoid major quality accidents, ensure construction quality, shorten The effect of structure length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

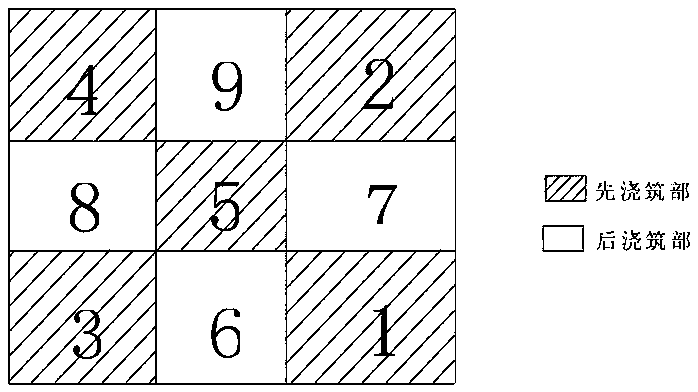

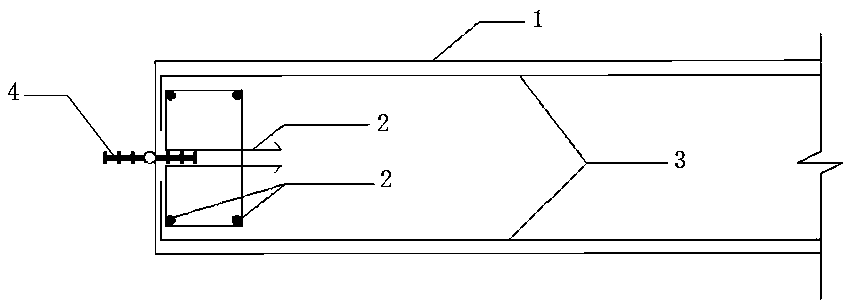

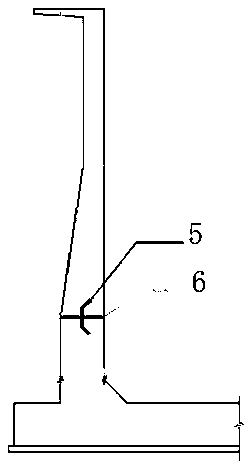

[0060] This embodiment will be described in detail in conjunction with an engineering example. The length*width*height of the AAO reaction pool in a water purification and sewage treatment plant project undertaken by Sinochem Second Construction Group Co., Ltd. is 84.8m*67.5m*6.6m, with a design capacity of 30,000 cubic meters and a maximum capacity of about 36,000 cubic meters. It is a unit combined reinforced concrete sewage tank. The whole pool is divided into 9 independent plate units by four longitudinal and transverse deformation joints, such as the pool bottom plate, wall plate, inner partition wall, upper diversion channel, and 30mm wide deformation joints are set between adjacent plate units. , The deformation joint relies on the buried rubber waterstop to connect 9 independent plate units to form a whole, and the waterproof and water stop at the deformation joint is completely guaranteed by the buried rubber waterstop. The pool wall is a special-shaped variable sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com