Field detection device, system and method for achieving no maintenance of gas density relay

A gas density and on-site detection technology, which is applied in the electric power field, can solve problems such as potential safety hazards, reduction of insulation strength on the surface of insulating parts, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

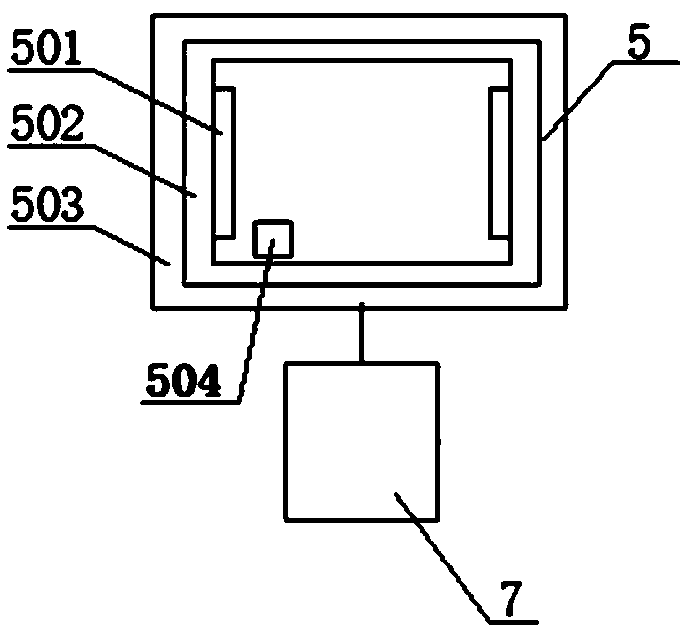

[0171] Such as figure 1 As shown, the on-site detection device includes a temperature adjustment mechanism 5 and an intelligent control unit 7 . The temperature adjustment mechanism 5, the temperature adjustment mechanism is configured to adjust the temperature rise and fall of the temperature compensation element of the gas density relay, so that the gas density relay generates a contact action and generates a contact signal; the intelligent control unit 7, It is connected with the temperature adjustment mechanism 5 and is configured to realize the control of the temperature adjustment mechanism 5; wherein, the contact signal includes alarm and / or lockout.

[0172] The temperature adjustment mechanism 5 of this embodiment is mainly composed of a heating element 501, a heat preservation piece 502, a controller 504, a temperature detector 3 (same as the temperature sensor), a temperature adjustment mechanism housing 503, and the like. The controller 504 may adopt PID control, ...

Embodiment 2

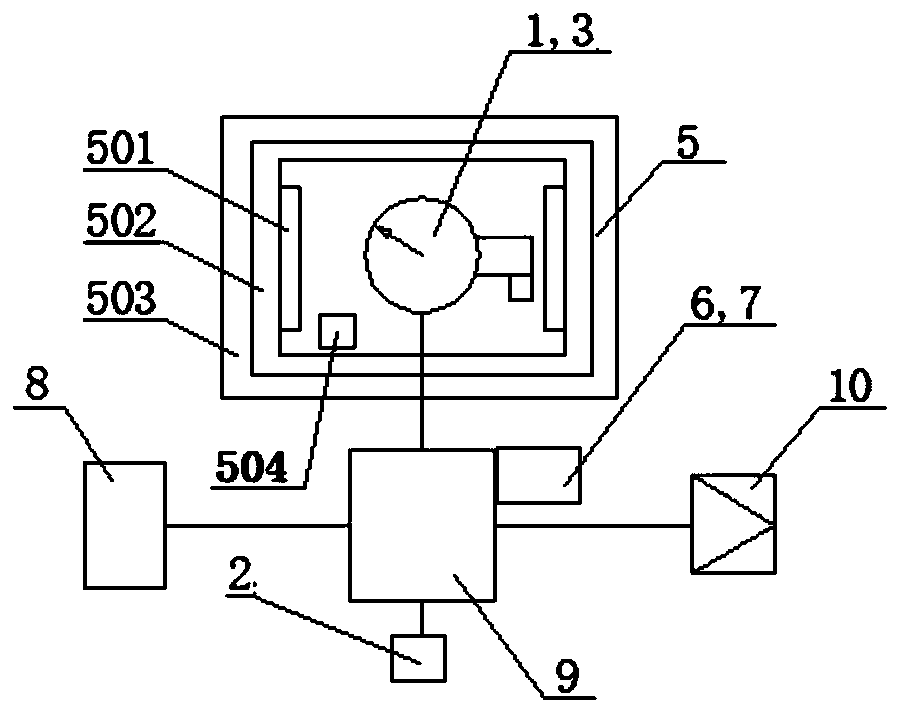

[0176] Such as figure 2 As shown, compared with the first embodiment, the on-site detection device of this embodiment adds a pressure sensor 2 , a temperature sensor 3 , an online verification contact signal sampling unit 6 , a multi-way joint 9 and an air supply interface 10 . The pressure sensor 2 and the air supply interface 10 are arranged on the multi-way joint 9 . The temperature adjustment mechanism 5 is arranged opposite to the gas density relay 1 , and the temperature sensor 3 is arranged in the casing of the density relay 1 . The gas density relay 1 and the gas supply interface 10 are set on the multi-way joint 9 , and the pressure sensor 2 , the online verification contact signal sampling unit 6 and the intelligent control unit 7 are set on the multi-way joint 9 . The temperature adjustment mechanism 5 is arranged outside the density relay 1 . Specifically, the density relay 1 communicates with the electrical equipment 8 through the multi-way joint 9; the pressur...

Embodiment 3

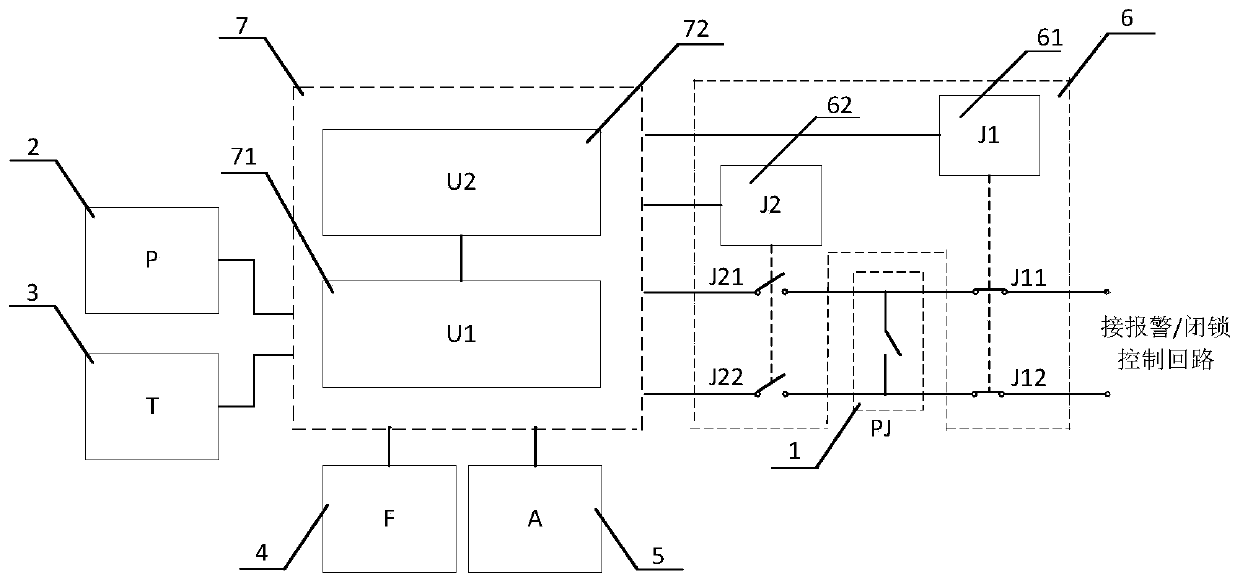

[0189] image 3 It is a schematic diagram of a control circuit of an on-site detection device.

[0190] The online verification contact signal sampling unit 6 mainly completes the sampling of the contact signal of the gas density relay 1 . That is, the basic requirements or functions of the on-line verification contact signal sampling unit 6 are: 1) It does not affect the safe operation of electrical equipment during verification, that is, when the contact of the gas density relay 1 moves during verification, it will not affect the electrical equipment. Safe operation of the equipment; 2) The contact signal control circuit of the gas density relay 1 does not affect the performance of the on-site detection device, especially the performance of the intelligent control unit 7, and does not cause damage to the on-site detection device or affect the test work.

[0191] Such as image 3 As shown, the online verification contact signal sampling unit 6 of this embodiment is mainly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com