Power distribution operation robot wire clamp pose tracking and matching method based on model

An operation robot and matching method technology, which is applied in the field of model-based power distribution operation robot wire clamp position and attitude tracking and matching to achieve the effects of reducing the scope, improving the operation efficiency, and reducing the strength and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

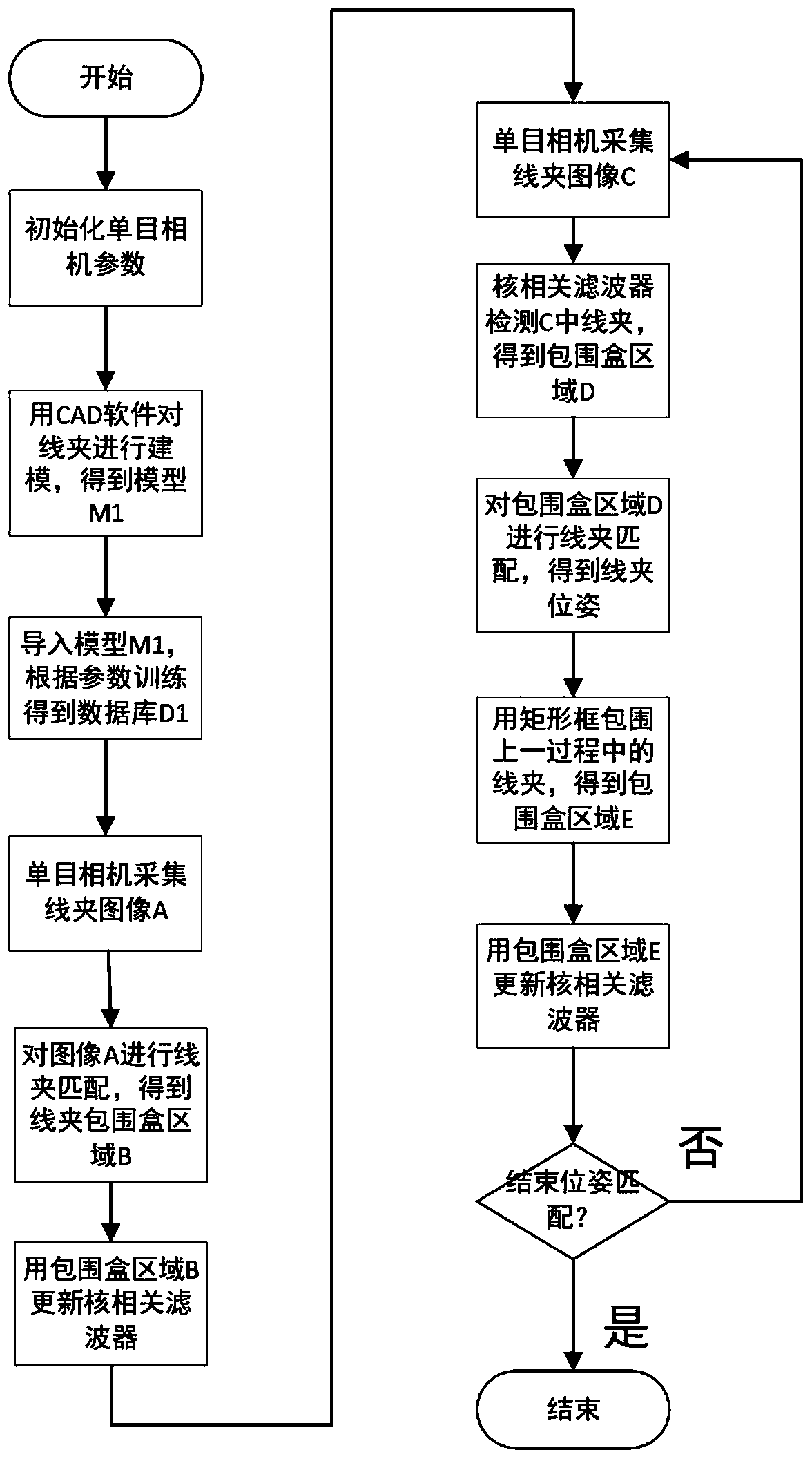

[0048] The model-based tracking and matching method of the wire clamp position and posture of the power distribution operation robot of the present invention includes the following contents:

[0049] 1. Initialize the monocular camera parameters, as shown in Table 1 below.

[0050] Table 1 Calibration results of monocular camera parameters

[0051]

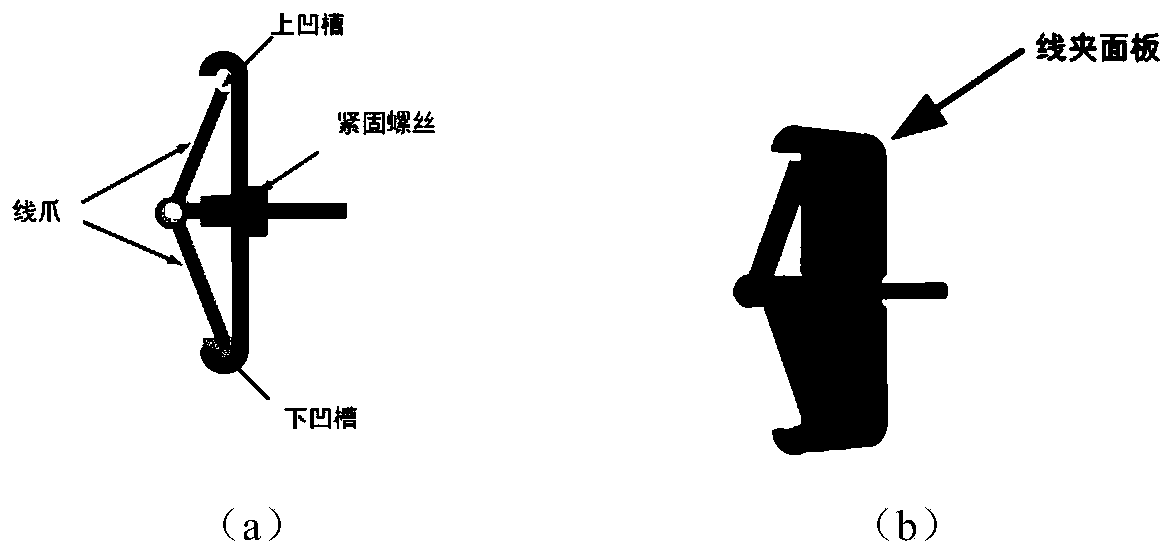

[0052] 2. Using Auto CAD software to figure 2 The clip shown in (a) is modeled, and the model M1 is obtained as figure 2 As shown in (b), the panel part of the clip is the basis for pose matching.

[0053] The CAD model of the target object contains the information and size information of each surface of the object, and the target is modeled using Auto CAD software and saved as a dxf format file. In order to describe the target object conveniently in the spherical coordinate system, the origin of the coordinate system defined during modeling will be translated to the center of the cube that least encloses the CAD model. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com