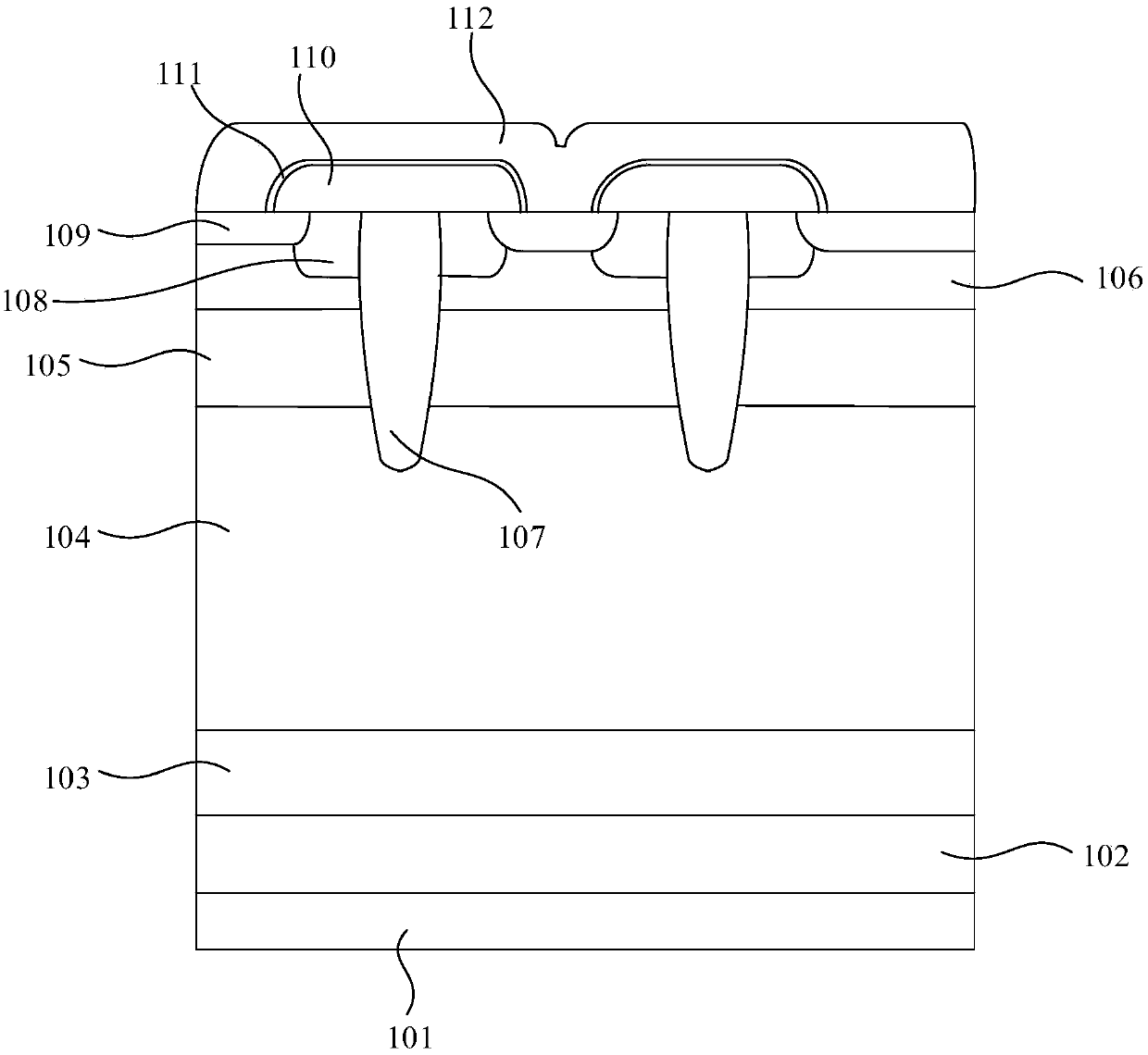

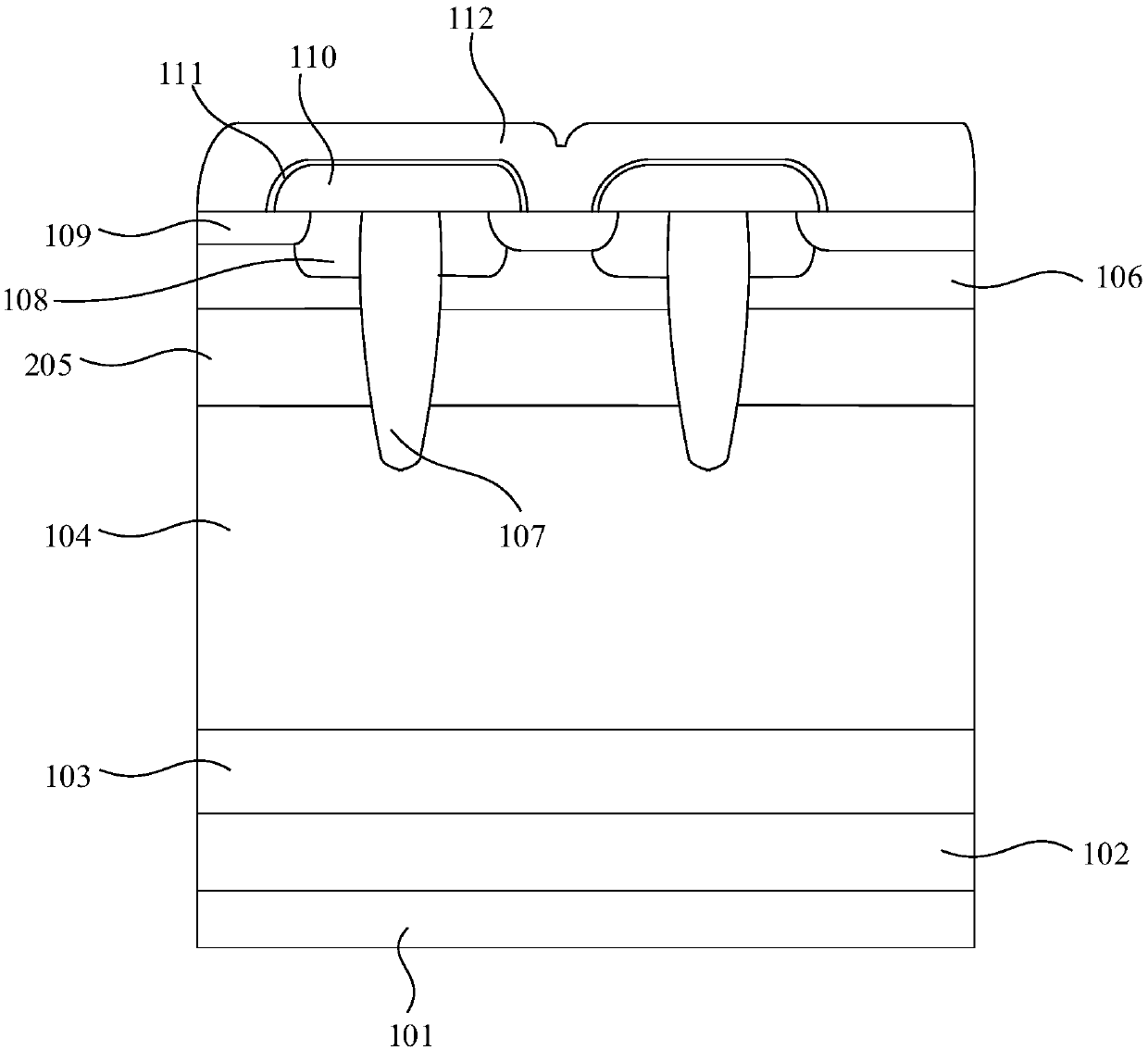

IGBT and manufacturing method thereof

A manufacturing method and carrier storage technology, which is applied in the field of IGBT manufacturing, can solve the problems of long minority carrier life of IGBT, and achieve the effects of shortening minority carrier life, lowering saturation voltage, and reducing saturation voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below by means of a preferred embodiment, but the present invention is not limited to the scope of the described embodiment.

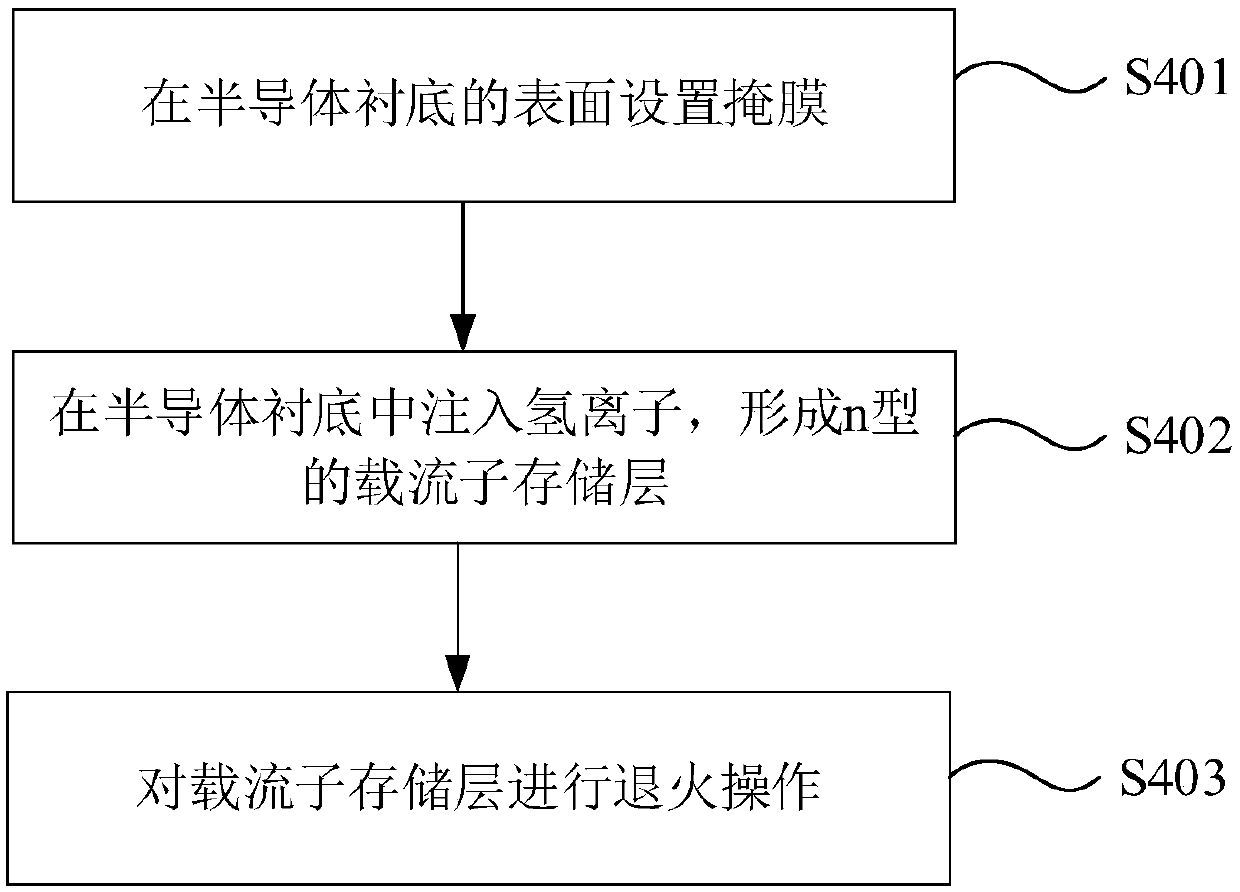

[0040] For the IGBT manufacturing method of this embodiment, refer to figure 2 , including the following steps:

[0041] S402, implanting hydrogen ions into the semiconductor substrate to form an n-type carrier storage layer.

[0042] In order to effectively implant hydrogen ions into the target area and avoid implanting hydrogen ions into non-target areas, such as figure 2 As shown, before hydrogen ion implantation, the IGBT manufacturing method of this embodiment includes the following steps:

[0043] S401, setting a mask on the surface of the semiconductor substrate, the mask includes a blocking area and a transmission area, the blocking area is used to block hydrogen ions from being implanted into the semiconductor substrate; the transmission area is used to allow hydrogen ions to pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com