Capacity configuration optimization method for alternating current-direct current hybrid microgrid

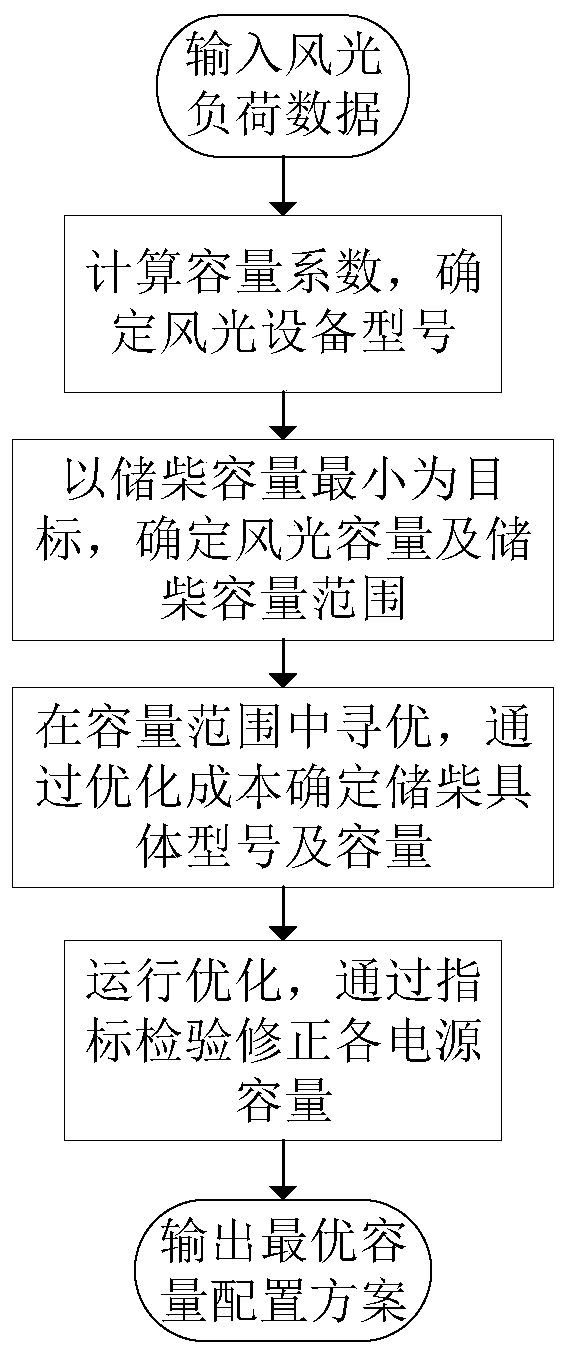

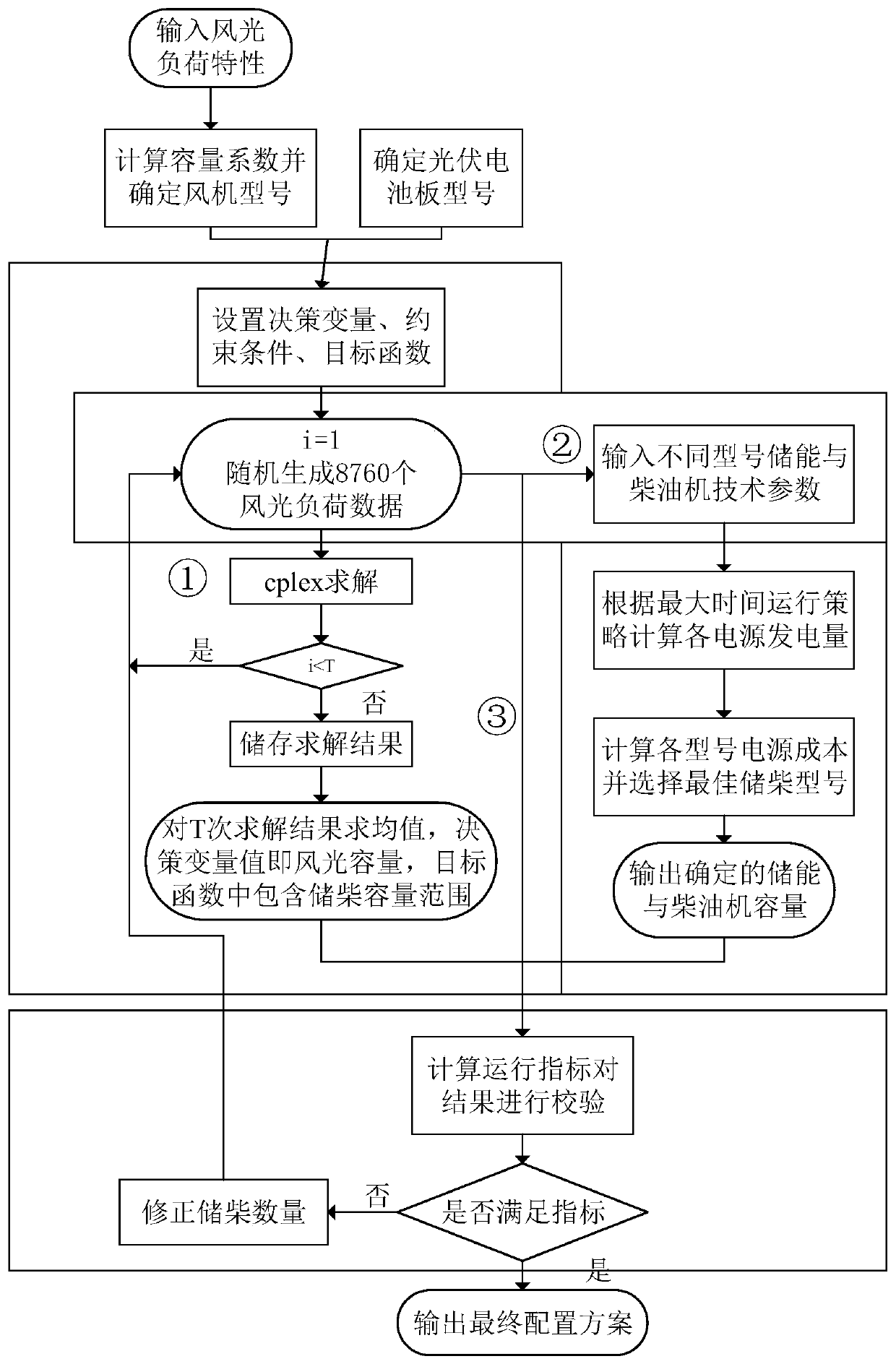

A technology of AC-DC hybrid and capacity allocation, which is applied in the direction of AC network load balancing, photovoltaic power generation, wind power generation, etc., can solve problems such as low power generation efficiency, affecting the economic benefits of micro-grids, and inaccurate results of micro-grid capacity optimization, to achieve improved Utilization rate, good large-scale renewable energy grid connection, and the effect of ensuring reliability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

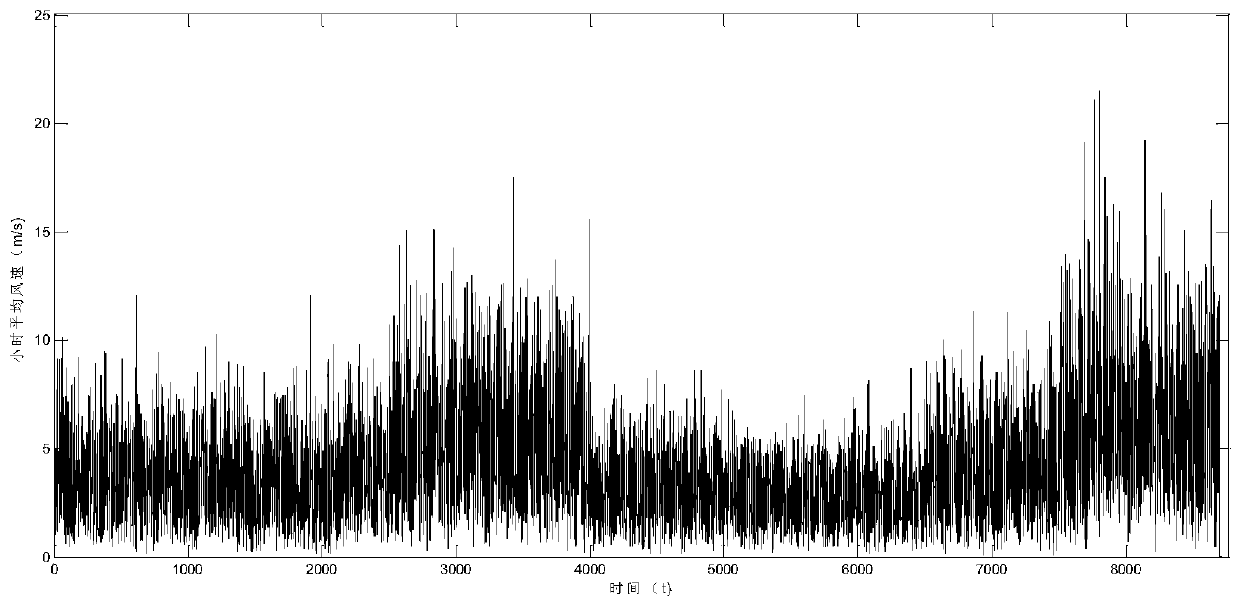

[0112] Taking a certain area in Hubei as an example, it is known that the typical annual hourly average wind speed in this area is as follows: image 3 As shown, the hourly average light intensity is as follows Figure 4 The hourly average ambient temperature is shown as Figure 5 As shown, the hourly average DC load is Figure 6 shown and the hourly average AC load as Figure 7 As shown, and the proposed microgrid topology is as follows Figure 8 shown. The invention optimizes the capacity configuration of the proposed microgrid in the area based on the CPLEX software.

[0113] Step 1: Fan model selection

[0114] Calculate the capacity coefficient of each type of fan as shown in Table 1. No. 7 fan has the largest capacity coefficient, so choose this type of wind turbine.

[0115] Table 1 Fan parameters of each model

[0116] serial number model P r

v ci

v r

v co

capacity factor 1 GROWIANI 3000 6.3 11.8 24 0.378 2 WTS-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com