Trimethylindium low-temperature purification device and low-temperature purification method

A technology of trimethyl indium and a purification method, which is applied in the field of low temperature purification devices of trimethyl indium, can solve the problems that the safety and stability of the purification process are difficult to control, the equipment cost is large, and the equipment requirements are high, and the equipment cost is low. , The effect of low equipment requirements and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

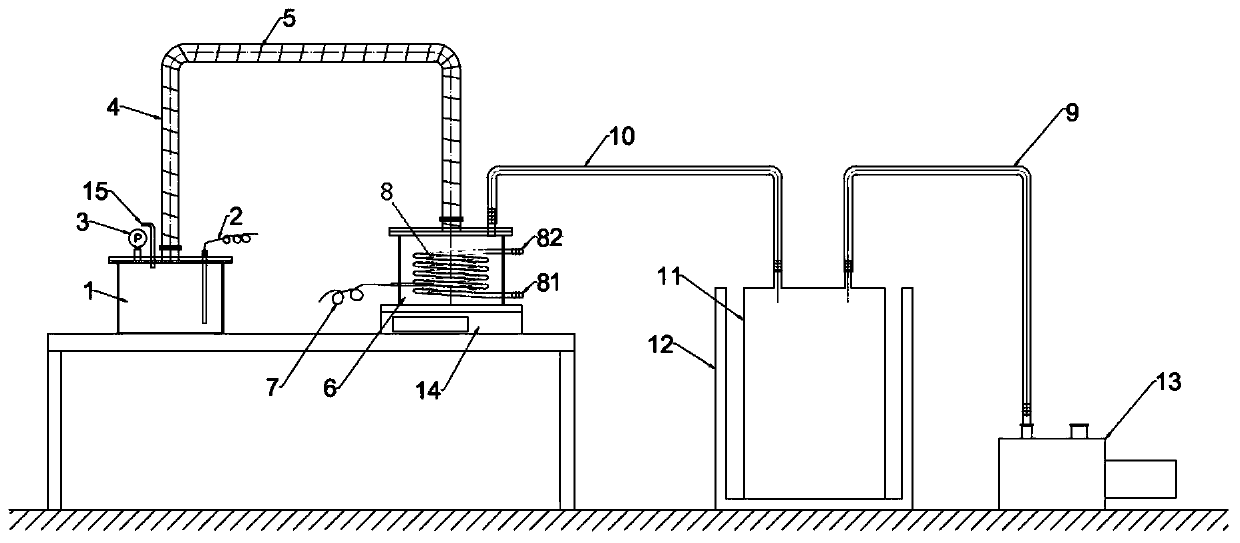

[0037] The method for the low-temperature purification of trimethylindium comprises the steps:

[0038] (1) Put the purified raw material kettle 1 and the receiving tank 6 in an inert gas glove box, put 500 grams of 99% pure trimethylindium material into the purified raw material kettle 1, and seal the purified raw material kettle 1, Inject liquid nitrogen into the Dewar tank 12;

[0039](2) The cooling medium inlet 81 and the cooling medium outlet 82 of the condensing device 8 are connected to the external cooling equipment, and according to the indication of the thermometer 7 in the receiving tank, the temperature in the receiving tank 6 is controlled at -20 by the condensing device 8 ℃;

[0040] (3) open the vacuum pump 13, vacuumize the purified raw material still 1, and according to the indication of the pressure gauge 3, control the pressure in the purified raw material still 1 to be 30torr;

[0041] (4) The low-temperature heating device carries out low-temperature he...

Embodiment 2

[0043] The method for the low-temperature purification of trimethylindium comprises the steps:

[0044] (1) Place the purified raw material kettle 1 and the receiving tank 6 in an inert gas glove box, put 600 grams of 99% pure trimethylindium material into the purified raw material kettle 1, and seal the purified raw material kettle 1, Inject liquid nitrogen into the Dewar tank 12;

[0045] (2) The cooling medium inlet 81 and the cooling medium outlet 82 of the condensing device 8 are connected to the external cooling equipment, and according to the indication of the thermometer 7 in the receiving tank, the temperature in the receiving tank 6 is controlled at -10 by the condensing device 8 ℃;

[0046] (3) open the vacuum pump 13, vacuumize the purified raw material still 1, and according to the indication of the pressure gauge 3, control the pressure in the purified raw material still 1 to be 40torr;

[0047] (4) The low-temperature heating device carries out low-temperature...

Embodiment 3

[0049] The method for the low-temperature purification of trimethylindium comprises the steps:

[0050] (1) Place the purified raw material kettle 1 and the receiving tank 6 in an inert gas glove box, put 700 grams of solid trimethylindium material with a purity of 99% into the purified raw material kettle 1, and seal the purified raw material kettle 1, Inject liquid nitrogen into the Dewar tank 12;

[0051] (2) The cooling medium inlet 81 and the cooling medium outlet 82 of the condensing device 8 are connected to the external cooling equipment, and according to the indication of the thermometer 7 in the receiving tank, the temperature in the receiving tank 6 is controlled at 10°C by the condensing device 8 ;

[0052] (3) open the vacuum pump 13, vacuumize the purified raw material still 1, and according to the indication of the pressure gauge 3, control the pressure in the purified raw material still 1 to be 45torr;

[0053] (4) The low-temperature heating device carries o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com