High-quality manufactured sand production process with sand grinder and dry-method centrifugal powder removal and classification

A production process and technology of machine-made sand, which is applied in the direction of grain processing, etc., can solve the problem of lack of high-quality machine-made sand, and achieve the effect of making up for the technical gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

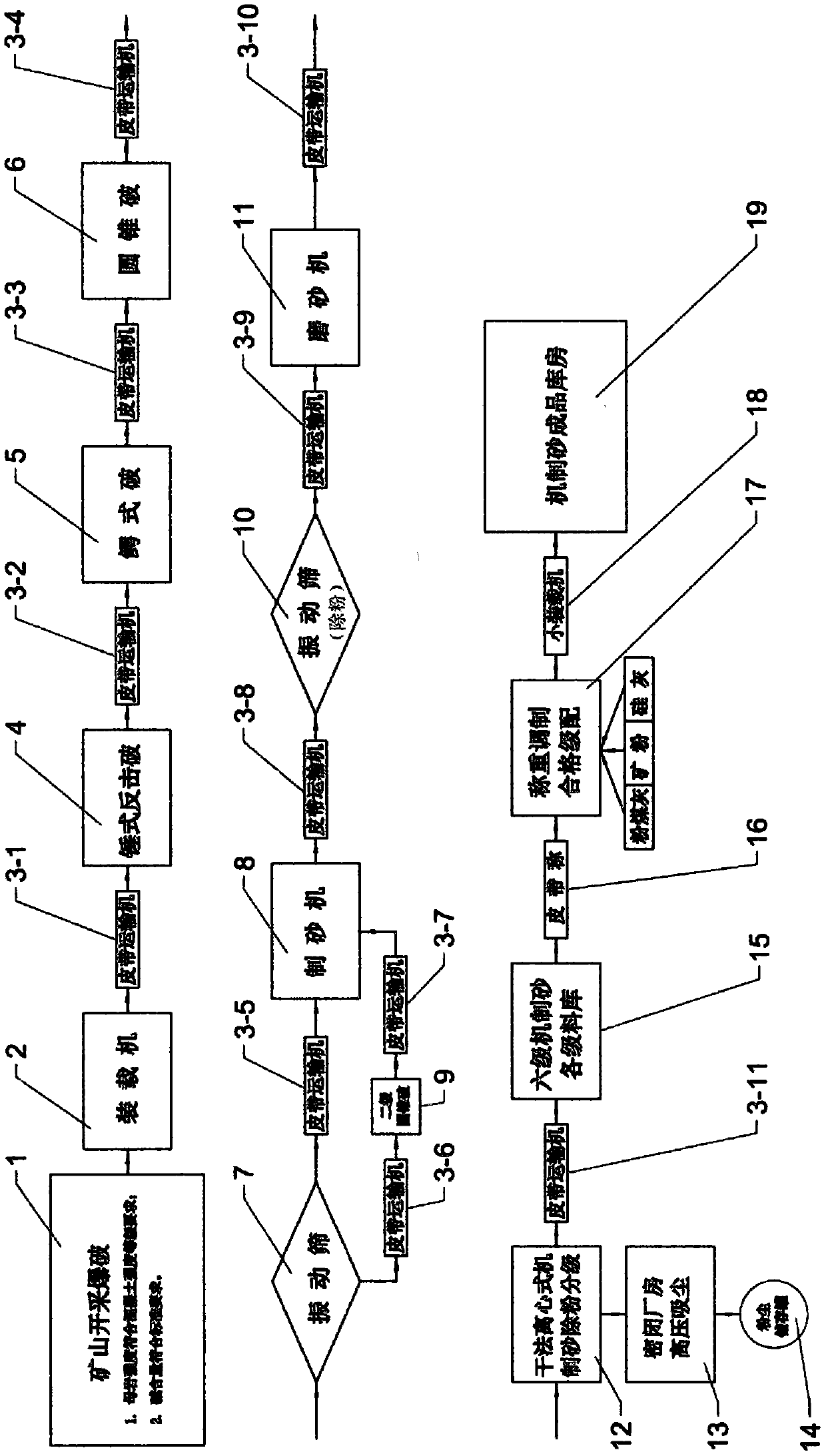

[0025] Such as figure 1 As shown, the production process of high-quality machine-made sand with a sander and dry centrifugal powder removal and classification according to the present invention includes: mining blasting 1, loader transportation 2, hammer impact crusher crushing 4, crocodile type Crusher crushing 5, cone crusher crushing 6, vibrating screen screening 7, sand making machine-made sand 8, secondary cone crusher crushing again 9, vibrating screen 10, grinding machine 11, dry centrifugal machine-made sand powder removal and classification 12 , High-pressure dust collection in closed workshops 13, centralized treatment of dust storage tanks 14, six-level machine-made sand sub-warehouse storage 15, belt scale weighing 16, modulation qualified grading 17, small loader transportation 18, finished machine-made sand warehouse storage 19 and various Belt conveyor 3 is used for transmission between processes, and there are 19 processes in total. in:

[0026] a) The functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com