Soil directional conditioning agent and preparation method thereof, and method for planting alfalfa by using conditioning agent

A technology of alfalfa and conditioner, applied in the field of agricultural planting, can solve the problems of not effectively guaranteeing the yield of alfalfa, poor growth and poor yield, and achieve the effects of ensuring the yield of alfalfa, shortening the emergence time, and increasing the emergence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

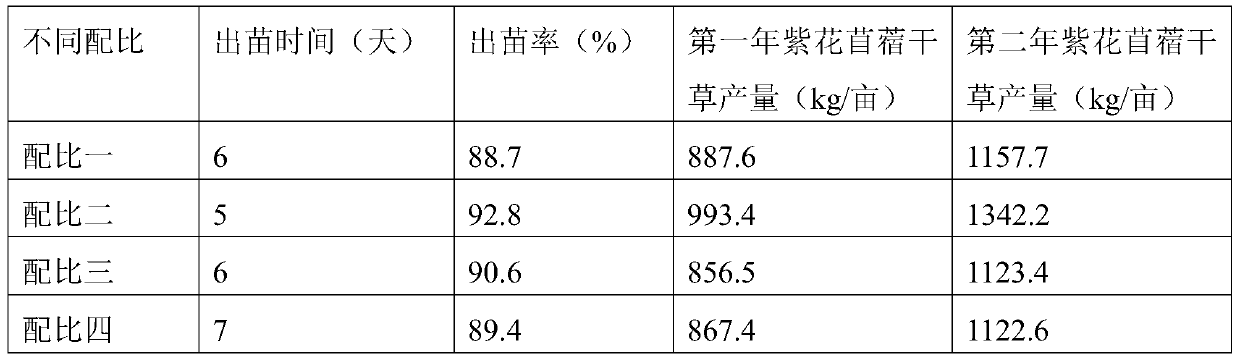

[0029] Proportion 1: desulfurized gypsum powder 25%, weathered coal 25%, decomposed cow dung 20%, rhizobia agent 10%, rice straw powder 10%, calcium sulfate 10%;

[0030] Proportion 2: desulfurized gypsum powder 25%, weathered coal 20%, decomposed cow dung 20%, rhizobia agent 10%, rice straw powder 15%, calcium sulfate 10%;

[0031] Proportion 3: 30% desulfurized gypsum powder, 20% weathered coal, 20% decomposed cow dung, 10% rhizobia agent, 10% rice straw powder, and 10% calcium sulfate;

[0032] Proportion 4: 25% desulfurized gypsum powder, 20% weathered coal, 20% decomposed cow dung, 15% rhizobia agent, 15% rice straw powder, 5% calcium sulfate;

[0033] Proportion five: 25% desulfurized gypsum powder, 20% weathered coal, 25% decomposed cow dung, 10% rhizobia agent, 15% rice straw powder, 5% calcium sulfate;

[0034] The preparation method of the soil directional conditioner: select an open and flat area, remove the debris on the ground, spread a layer of plastic film on t...

Embodiment 2

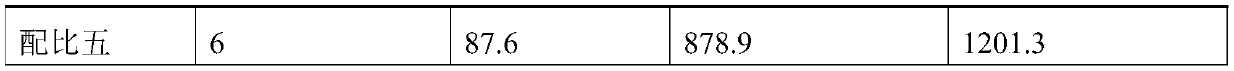

[0040] Embodiment 2. In the saline-alkali land of Xinjiang, the salt content is 3.5‰, and the pH is the saline-alkali land of 8.4

[0041] The operation of the experimental group is as follows: the planting soil is sandy soil, and the herbicide glyphosate is sprayed 15 days before the rotary tillage. It is required to spray on sunny days with no wind, spray evenly, 0.5 bottles per mu of land; before rotary tillage, Use a bulldozer to remove the surface salt crust at a depth of 10cm; after removing the surface salt layer, use a rotary tiller to till the land at a depth of 25cm, there are no large soil clods on the ground, and the soil is evenly crushed; after the land is rotary tilled, apply a fertilizer spreader to spread Soil directional conditioner (25% of desulfurized gypsum powder, 20% of weathered coal, 20% of decomposed cow dung, 10% of rhizobia agent, 15% of rice straw powder, 10% of calcium sulfate) 50kg / mu; after applying the soil directional conditioner , use the rot...

Embodiment 3

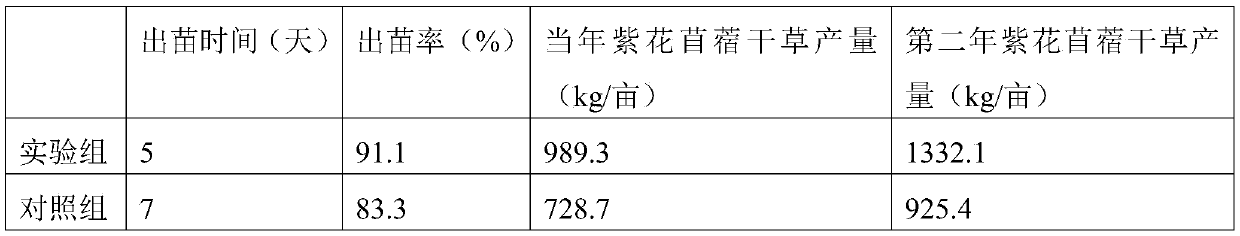

[0045] Example 3. Saline-alkali land in Xinjiang with a salt content of 3.8‰ and a pH of 8.1.

[0046]The operation of the experimental group is as follows: the planting soil is sandy soil, and the herbicide glyphosate is sprayed 18 days before the rotary tillage. It is required to spray on sunny days with no wind, spray evenly, 0.5 bottles per mu of land; before rotary tillage, Use a bulldozer to remove the surface salt crust, with a depth of 12cm; after removing the surface salt layer, use a rotary tiller to till the land at a depth of 20cm, there are no large soil clods on the ground, and the soil is evenly crushed; after the land is rotary tilled, apply a fertilizer spreader to spread Soil directional conditioner (25% of desulfurized gypsum powder, 20% of weathered coal, 20% of decomposed cow dung, 10% of rhizobia agent, 15% of rice straw powder, 10% of calcium sulfate) 60kg / mu; after applying the soil directional conditioner , use the rotary tiller again for rotary tillag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com