Surface modification method of aramid fiber

A kind of aramid fiber, surface modification technology, applied in the direction of fiber treatment, fiber type, ultrasonic/sonic fiber treatment, etc., can solve the problems of poor bonding strength of aramid fiber surface interface, improve roughness and surface activity, Realize the effect of large-scale industrial production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

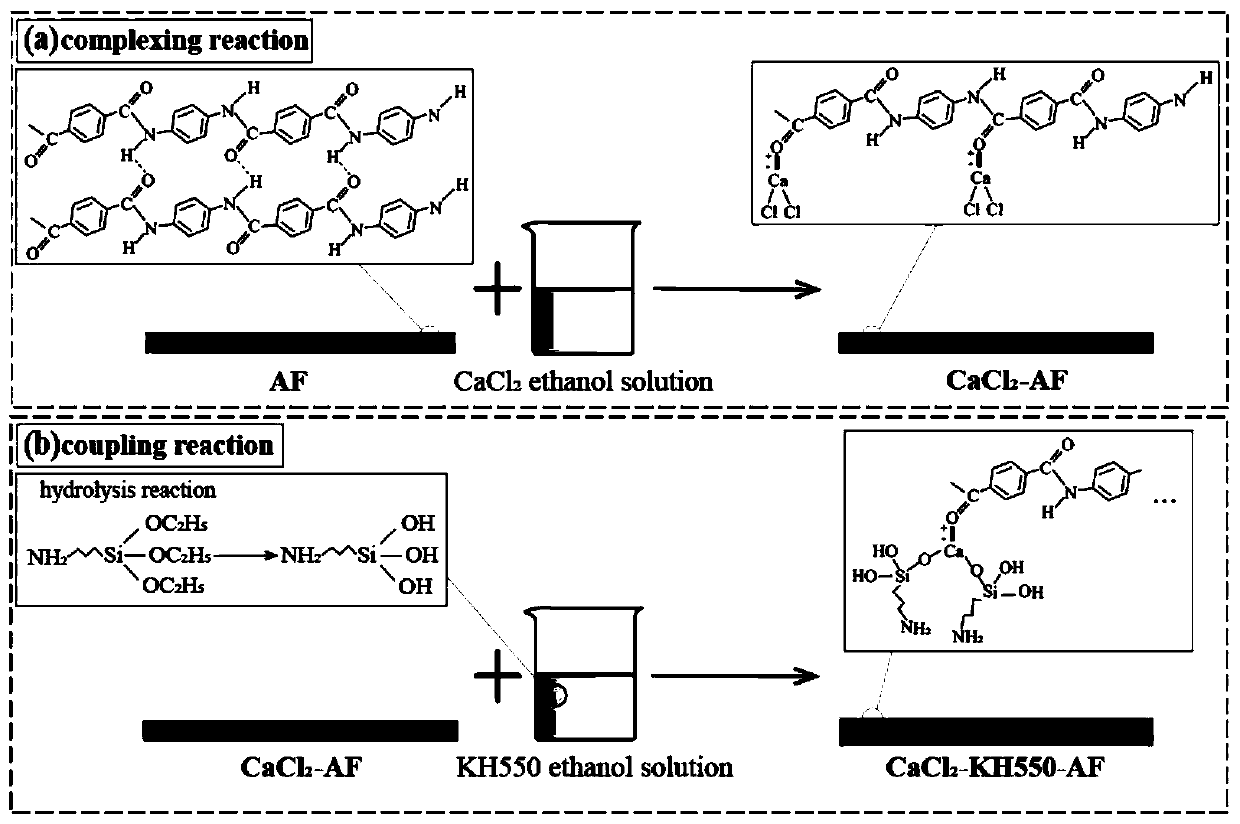

[0038] This embodiment provides a method for modifying aramid fibers with a silane coupling agent, including three steps: surface ultrasonic cleaning, surface complexation reaction, and silane coupling agent surface grafting reaction. The specific implementation steps are as follows:

[0039] 1. Ultrasonic cleaning of aramid fiber surface:

[0040] (1) Place the aramid fiber in acetone or ethanol solution, and use an ultrasonic cleaner to vibrate and clean at room temperature for 2 hours. After cleaning, take out the fiber and rinse it repeatedly with deionized water for 10 minutes;

[0041] (2) Place the aramid fibers cleaned in step (1) in a drying oven with the temperature controlled at 70°C, vacuum-dry for 4 hours, and then take them out for later use;

[0042] 2. Surface complexation reaction of complexing agent ethanol solution

[0043] (1) Place the cleaned and dried aramid fiber in the reaction kettle, inject the complexing agent CaCl 2Ethanol solution, the mass frac...

Embodiment 2

[0062] This embodiment provides a method for modifying aramid fiber with a silane coupling agent, which includes three steps: ultrasonic cleaning of the surface of the aramid fiber, surface complexation reaction of complexing agent ethanol solution, and surface grafting reaction of silane coupling agent. The implementation steps are as follows:

[0063] 1. Ultrasonic cleaning of aramid fiber surface:

[0064] (1) Place the aramid fiber in acetone or ethanol solution, and use an ultrasonic cleaner to vibrate and clean at room temperature for 1.5 hours. After cleaning, take out the fiber and rinse it repeatedly with deionized water for 5 minutes;

[0065] (2) Place the aramid fibers cleaned in step (1) in a drying oven with the temperature controlled at 60°C, vacuum-dry for 3 hours, and then take them out for use;

[0066] 2. Surface complexation reaction of complexing agent ethanol solution

[0067] (1) Place the cleaned and dried aramid fibers in the reactor, inject complexi...

Embodiment 3

[0075] This embodiment provides a method for modifying aramid fiber with a silane coupling agent, which includes three steps: ultrasonic cleaning of the surface of the aramid fiber, surface complexation reaction of complexing agent ethanol solution, and surface grafting reaction of silane coupling agent. The implementation steps are as follows:

[0076] 1. Ultrasonic cleaning of aramid fiber surface:

[0077] (1) Place the aramid fiber in acetone or ethanol solution, and use an ultrasonic cleaner to vibrate and clean it at room temperature for 2.5 hours. After cleaning, take out the fiber and rinse it repeatedly with deionized water for 15 minutes;

[0078] (2) Place the aramid fibers cleaned in step (1) in a drying oven with the temperature controlled at 80° C., and take them out after vacuum drying for 5 hours;

[0079] 2. Surface complexation reaction of complexing agent ethanol solution

[0080] (1) Place the cleaned and dried aramid fiber in the reaction kettle and inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com