Small engineering vehicle driving main engine and floor machine

A technology for engineering vehicles and main engines, which is applied in construction and building construction, etc., can solve the problems of uneven concrete surface flatness, human injury, and low construction efficiency, so as to enhance the overall shape of the fuselage and reduce production costs. , the effect of reducing the weight of the fuselage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

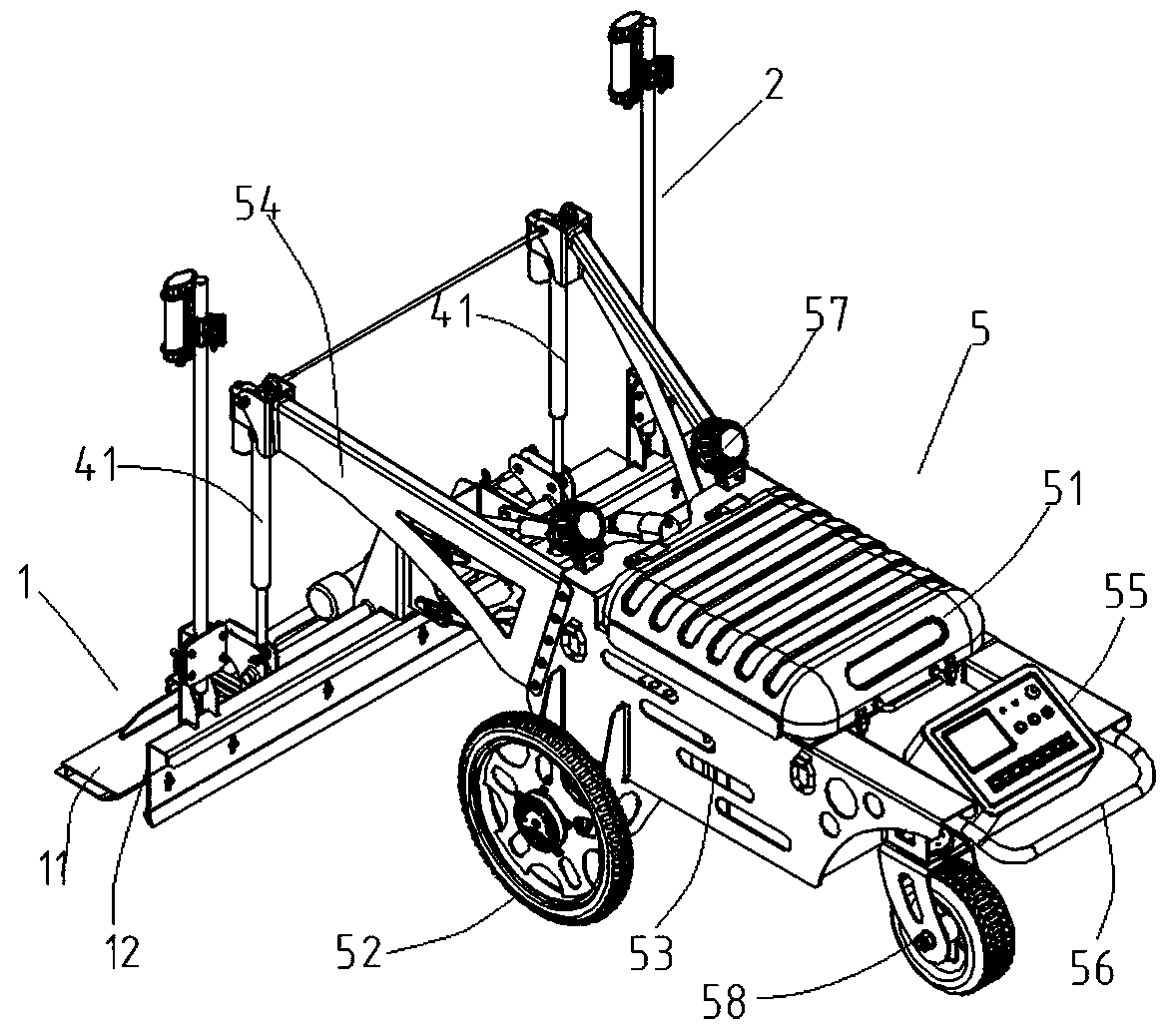

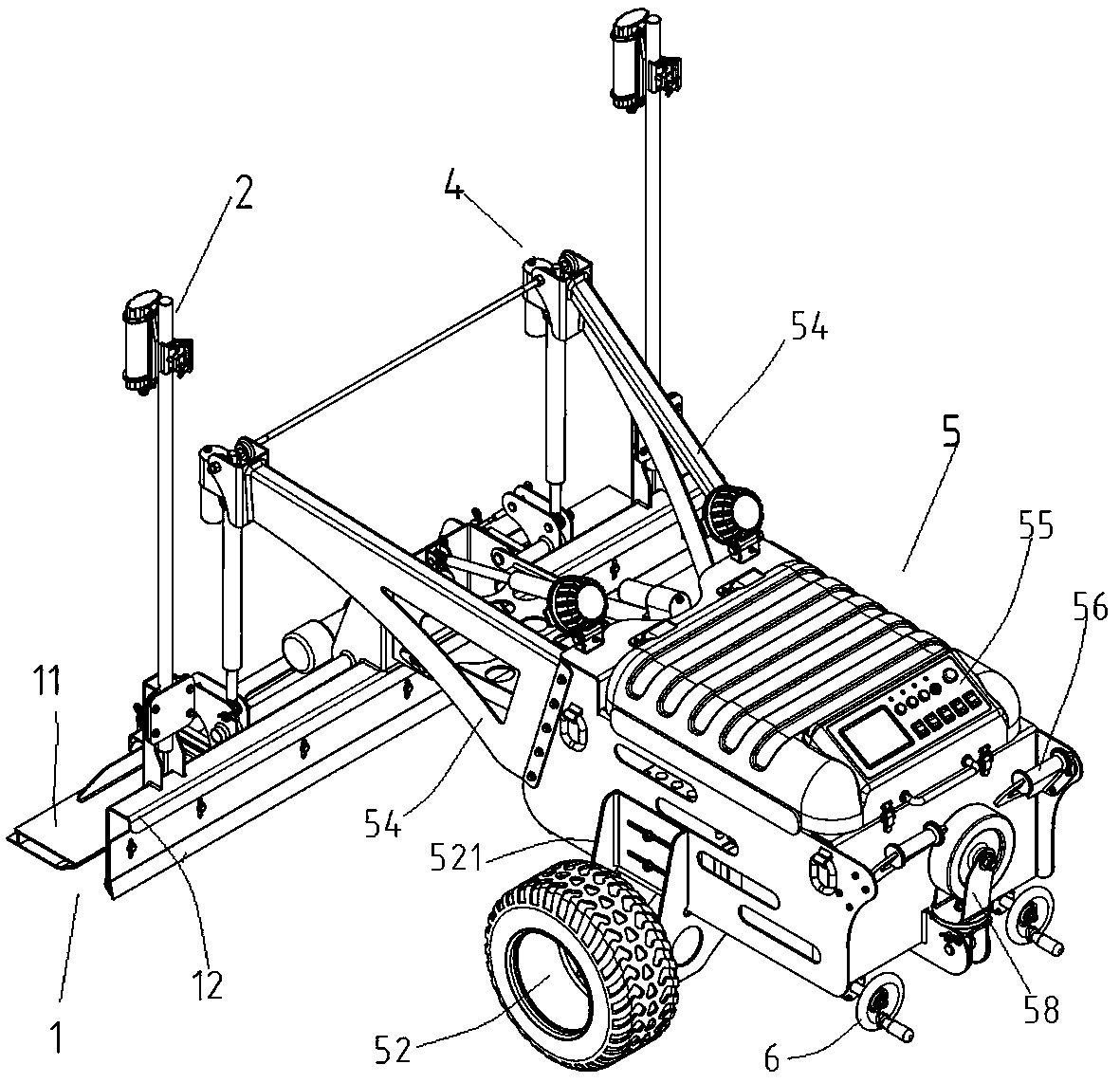

[0027] A small engineering vehicle drive main engine, including a casing 51, two hangers 54 inclined upwards for mounting attachments are fixed in front of the casing 51, and at least a pair of driving The wheel 52, the driving wheel 52 and the casing 51 are fixedly connected or connected with an adjustable center of gravity of the main engine.

[0028] The above-mentioned small engineering vehicle drives the main engine, the drive wheel 52 and the casing 51 are adjustable, and the casing 51 is provided with a lead screw 61, and one end of the lead screw 61 is screwed and matched with the wheel frame 521, The other end is provided with a handwheel 6; the wheel frame 521 is provided with several elongated holes and connected with the casing 51 through bolts, and the driving wheels 52 are arranged on the left and right sides of the wheel frame 521. When adjustment is required, first loosen the bolts, then turn the hand wheel to adjust the body of the main unit to a suitable posi...

Embodiment 2

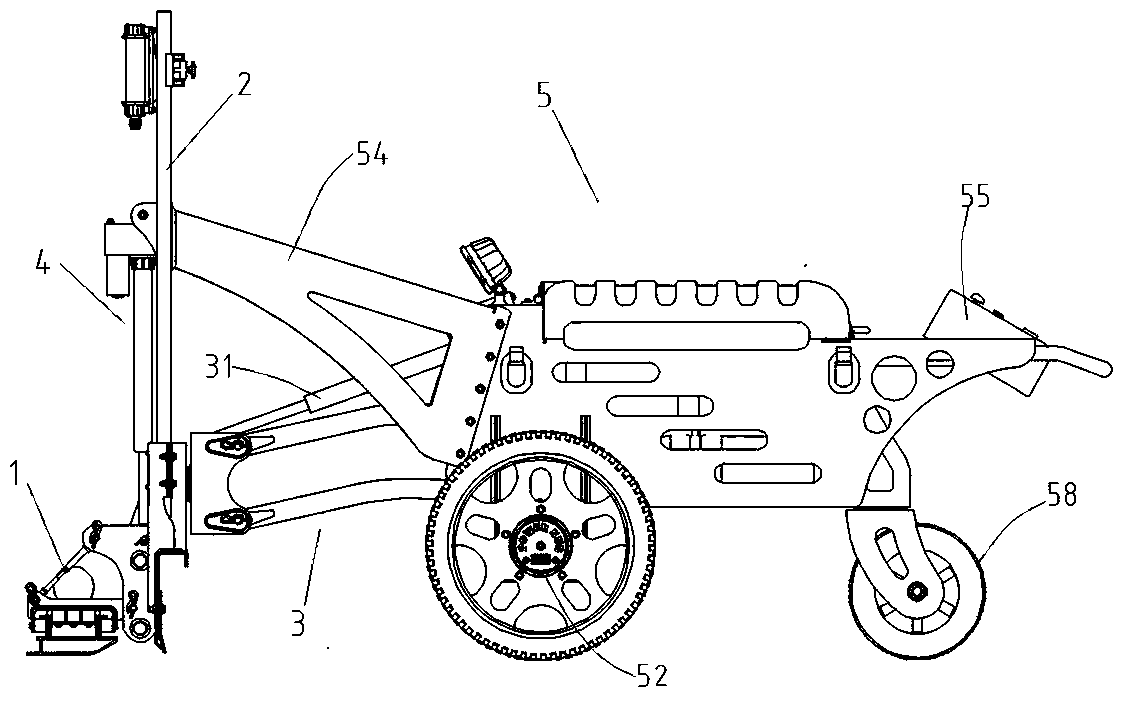

[0035] The main engine is driven by the small engineering vehicle in this embodiment, and the rear wheels 58 are foldable.

[0036] The rear wheel 58 is hinged to the casing 51 and a positioning pin is provided at the hinge to fix the position of the rear wheel 58 . Rear wheel 57 can be selected caster for use, and rear wheel 57 can be convenient to main engine to turn to after folding, and can play a supporting role when put down. The handle 56 can be cut into a certain shape with a plate, and the hand contact part is made into two semi-arc shapes with plastic or wooden materials and fixed on both sides of the plate to form an arc shape.

[0037] The present invention also provides a floor machine assembled by the above-mentioned main machine and leveling head. The whole machine is small in size, can be driven by electricity, is very environmentally friendly, and is convenient for indoor operation. The specific technical scheme is as follows:

[0038] The floor machine incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com