Angle type porous medium burner

A technology of porous media and burners, applied in the direction of burners, gas fuel burners, combustion types, etc., can solve the problems of burner backfire and defire instability, etc., to broaden the limit range of flame stability speed and improve outlet radiation Efficiency, the effect of preventing flame flashback and defiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

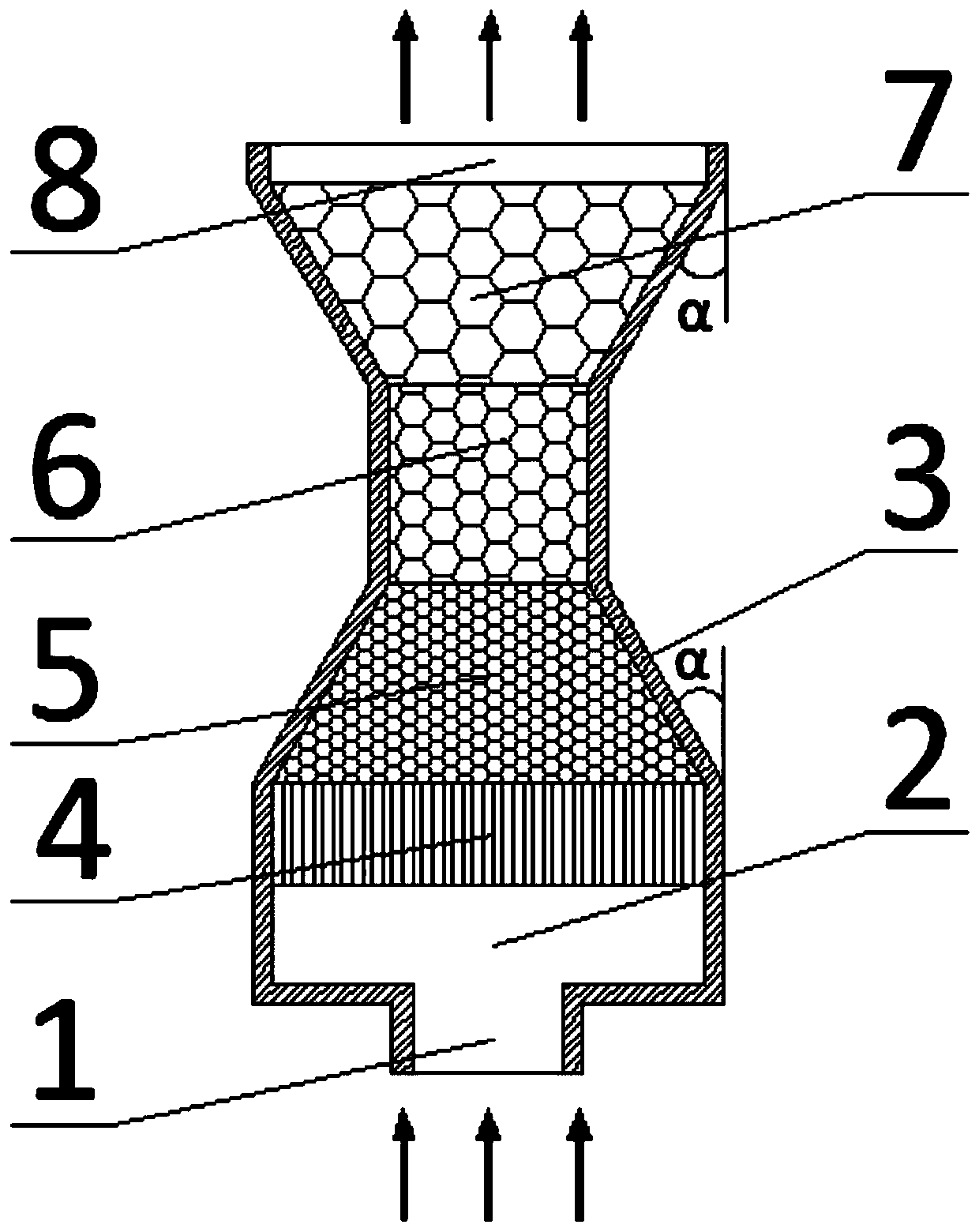

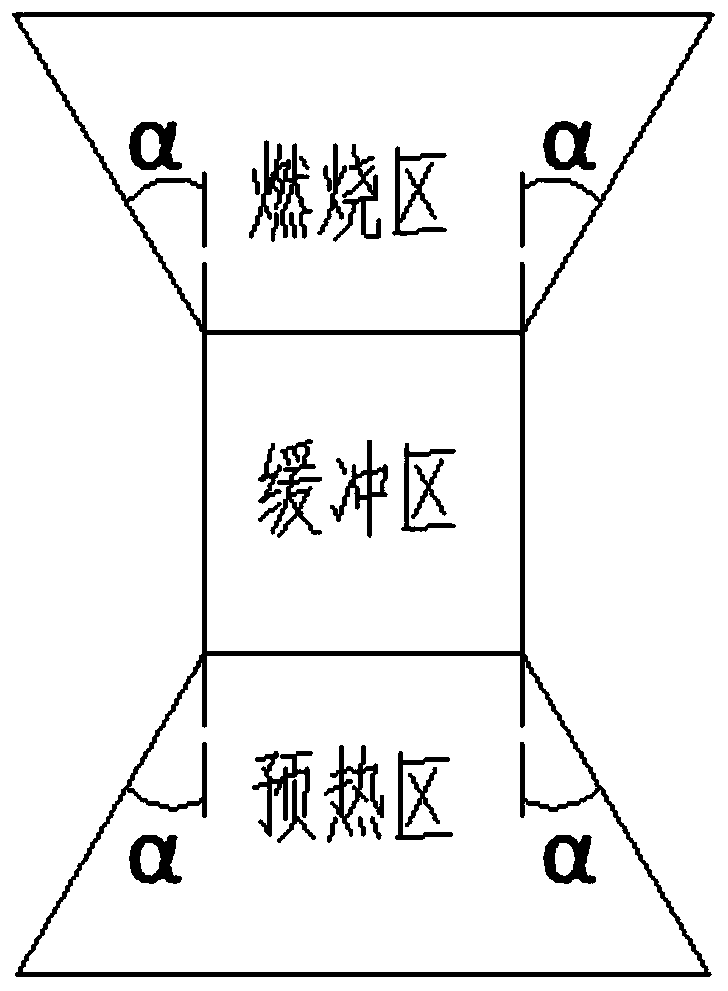

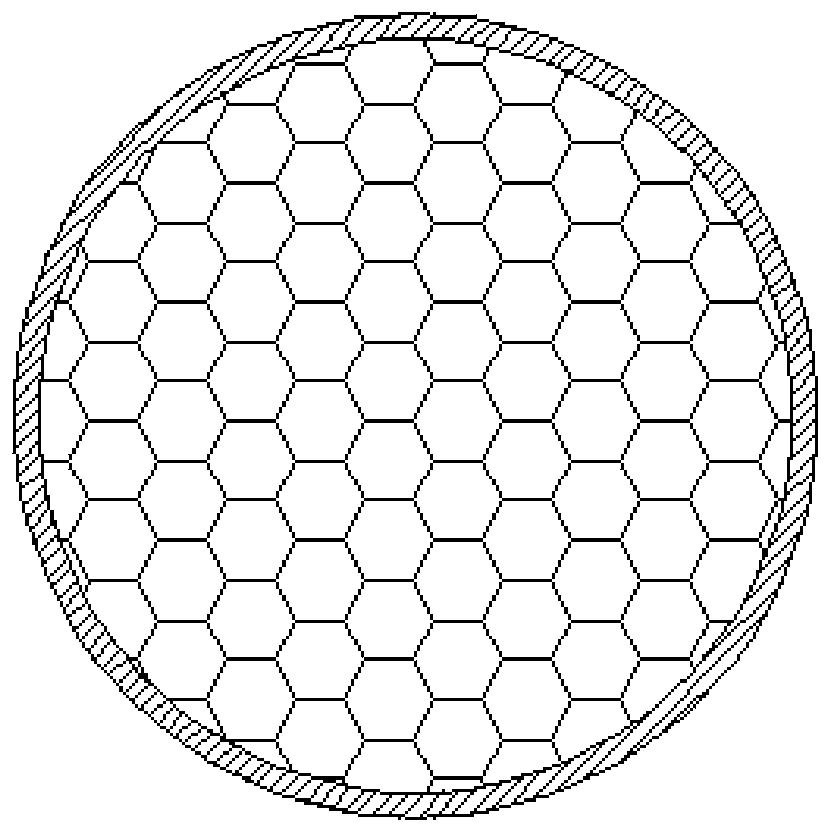

[0023] like Figure 1-3 As shown, an angle-shaped porous media burner is composed of gas inlet 1, combustion front chamber 2, protection zone 4, preheating zone 5, buffer zone 6, combustion zone 7 and flue gas outlet 8, surrounded by burner The casing 3 is closed, and the burner casing 3 is made of thermal insulation material. The preheating zone 5, the buffer zone 6, and the combustion zone 7 are collectively referred to as the porous medium zone. In the multi-media zone, the preheating zone 5 and the combustion zone 7 are funnel-shaped. , respectively set at both ends of the buffer zone 6, the preheating zone 5 and the combustion zone 7 are symmetrical about the center of the buffer zone 6. The protection are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

| Hole density | aaaaa | aaaaa |

| Hole density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com