Flue gas sampling device and method for power plant

A flue gas sampling and power plant technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of corrosion of the detection part and the failure of the detection part to continue to use, so as to reduce the degree of damage, facilitate the detection requirements, and have strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

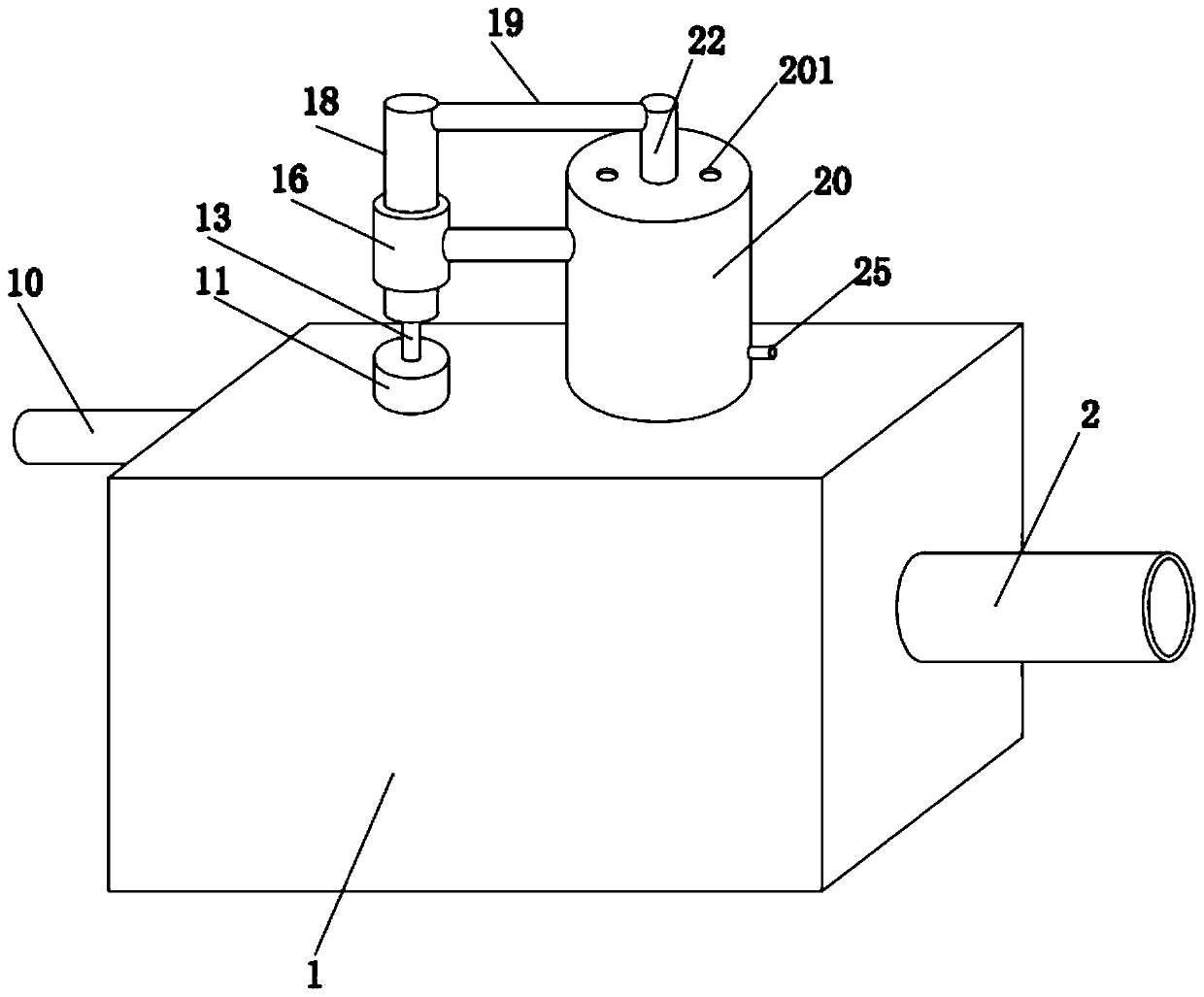

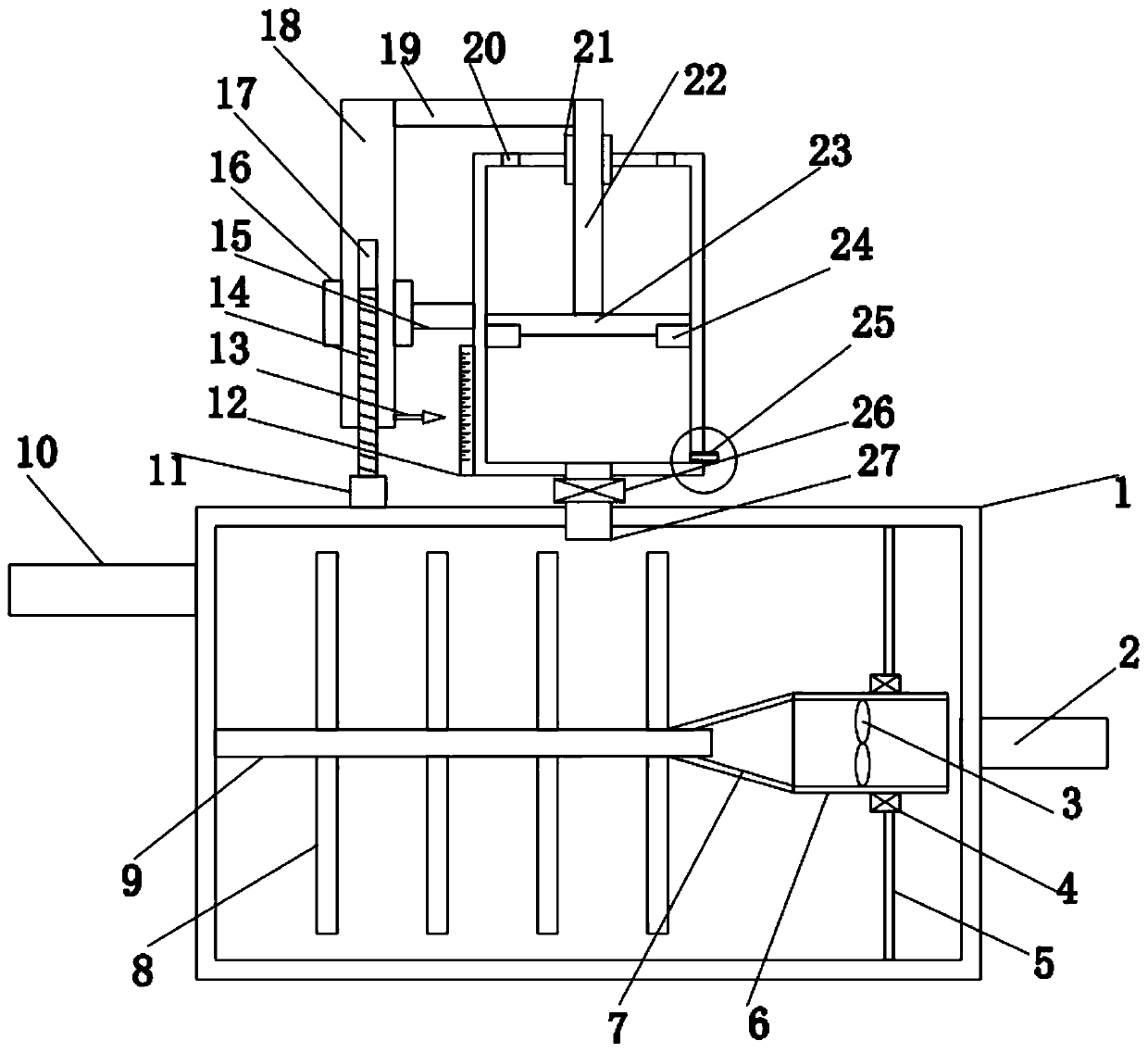

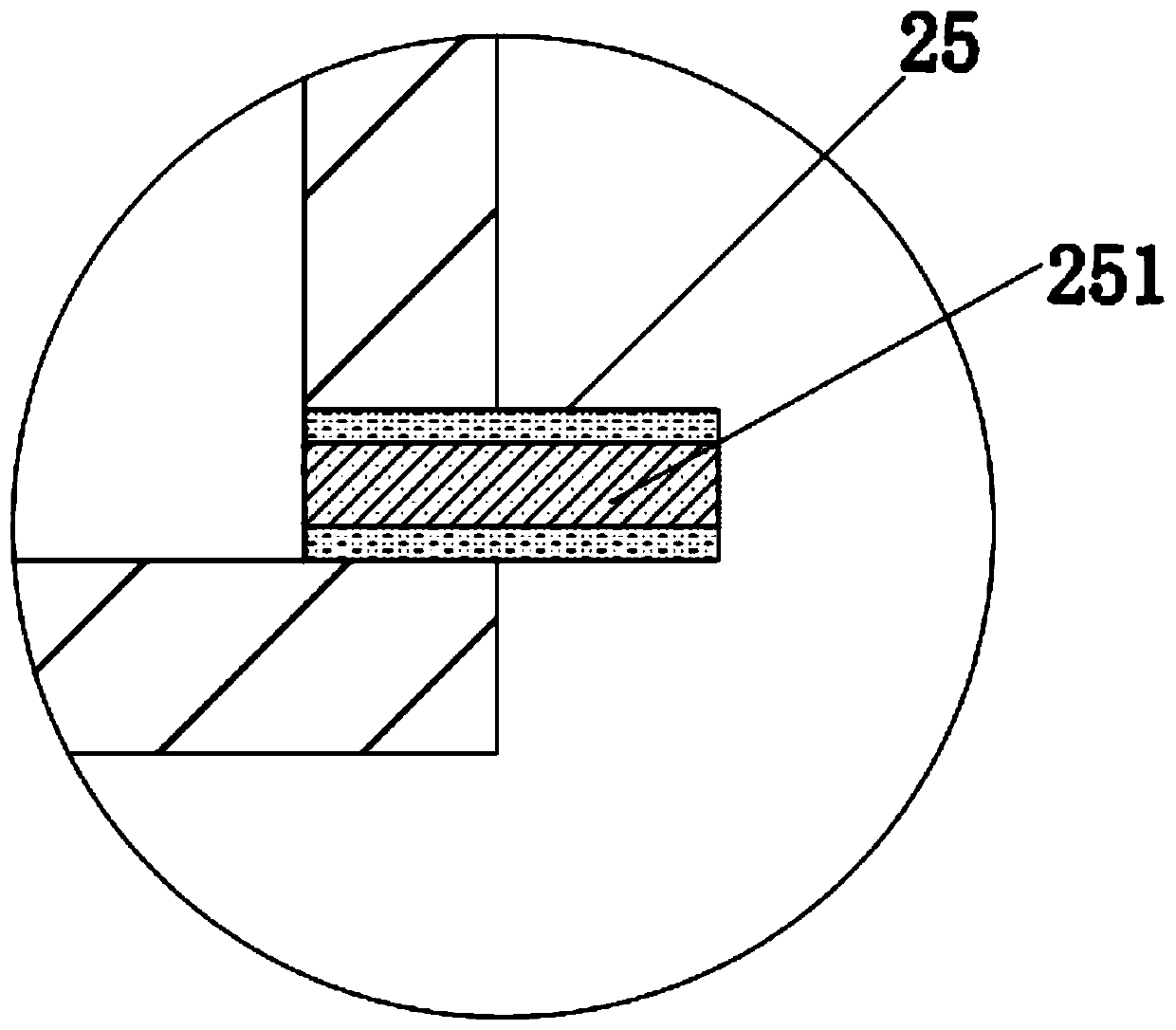

[0033] see Figure 1-3 , in an embodiment of the present invention, a flue gas sampling device for a power plant includes a buffer box 1 for buffering flue gas and an air inlet pipe 2 arranged at its inlet end, and the outlet end of the buffer box 1 is provided with a Exhaust air outlet pipe 10, the buffer box 1 is also provided with a mixing part and a piston part;

[0034] The mixing part is used to stir the gas inside the buffer box 1 evenly, so as to improve the accuracy of later detection;

[0035] The mixing part includes a fixed rotating shaft 9 whose left end is rotatably connected to the inner wall on the left side of the buffer box 1. The fixed rotating shaft 9 is coaxially arranged with the air intake pipe 2. Several stirring blades 8 are symmetrically arranged on the upper and lower sides of the fixed rotating shaft 9. , the right end of the fixed rotating shaft 9 is coaxially provided with an air guiding cylinder 6, the left end of the air guiding cylinder 6 is c...

Embodiment 2

[0045] see Figure 4 , in order to further improve the gas mixing effect, the stirring blade 8 is arranged in a rectangular shape, and at least one air guide cone hole 81 is arranged on the windward surface thereof, and the inner end of the air guide cone hole 81 communicates with the exhaust gas arranged at the end of the stirring blade 8 Passage 82, when stirring blade 8 rotates, the air on its windward side will enter along the air guide cone 81, and then be discharged from the exhaust passage 81, thereby generating an outward air flow, thereby further improving the mixing effect. Effect.

Embodiment 3

[0047] In order to improve the power gain value of the power fan blade 3, the structure of the air guide cylinder 6 is a conical tube with a large left end and a small right end, so that the air flow rate passing through the power fan blade 3 can be increased, and then it can obtain greater power. value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com