Spur-toothed cylindrical gear precision forging split-flow depressurization compound forming method and its mold

A spur gear and precision forging technology, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. The problems of low warm forging accuracy and oxidation of hot forging surface can achieve the effect of promoting radial flow and flow uniformity, high dimensional accuracy, and good forging structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

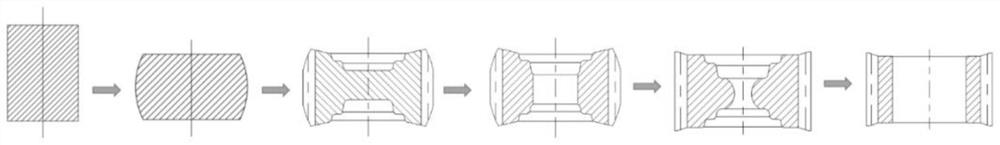

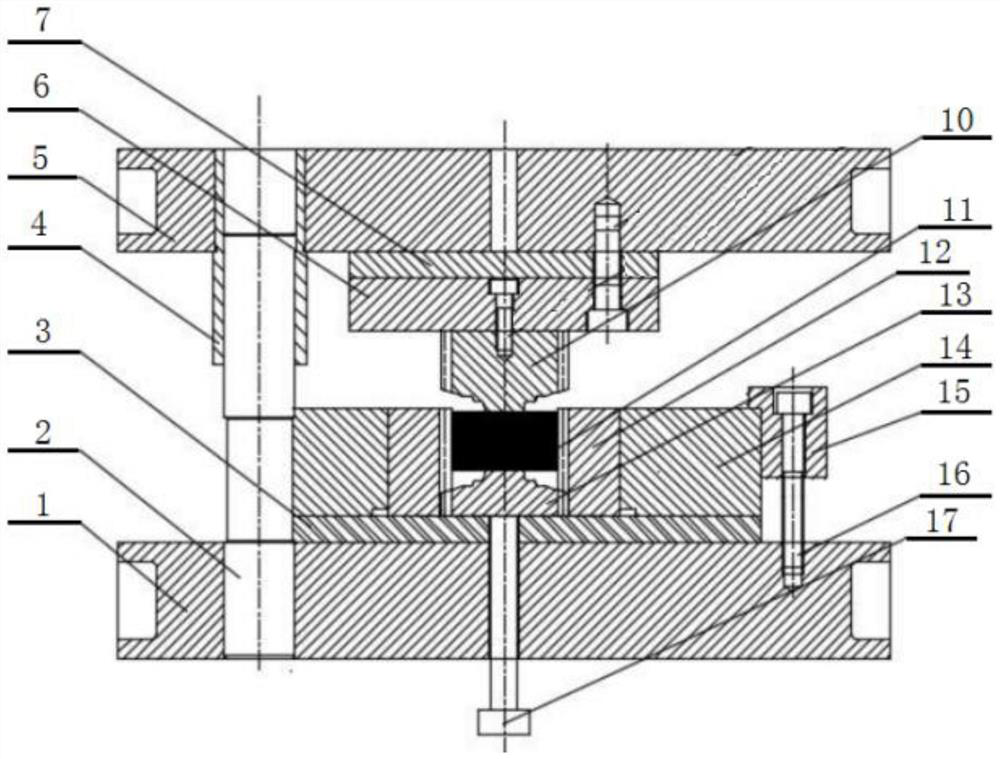

[0020] Specific implementation mode 1: In this implementation mode, a precision forging split-flow and step-down composite forming method for large-modulus spur gears for helicopters is specifically carried out according to the following steps:

[0021] 1. Blanking: According to the design of gear parts, the steel bar is cut to get the blank;

[0022] 2. Thickening: the blank is heated to 1160°C by a gas furnace, and the blank is placed on the roughening platform within 8 seconds after being taken out, the roughening pressure is set to 300T, the roughening pressure is 36mm, and the scale is removed to obtain the roughened blank;

[0023] 3. Hot forging and pre-forging: the thickened blank is transferred to the cavity of the hot forging pre-forging forming mold, and after being fixed, hot forging is carried out to obtain the pre-forging gear blank;

[0024] 4. Drill the center hole: Drill a center split hole with a diameter of 30 mm in the center of the pre-forged gear blank to...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the gear unilateral margin of the gear part described in step one is selected as 0.3mm, and the gear part volume V 0 =189691.2mm 2 , the oxidation amount of the part is taken as 3%, and the volume of the forging is V 1 =V 0 (1+3%)=195382mm 2 , considering that the size of the subsequent pier thick cylindrical blank is 52mm in diameter and 92mm in height. Others are the same as the first embodiment.

specific Embodiment approach 3

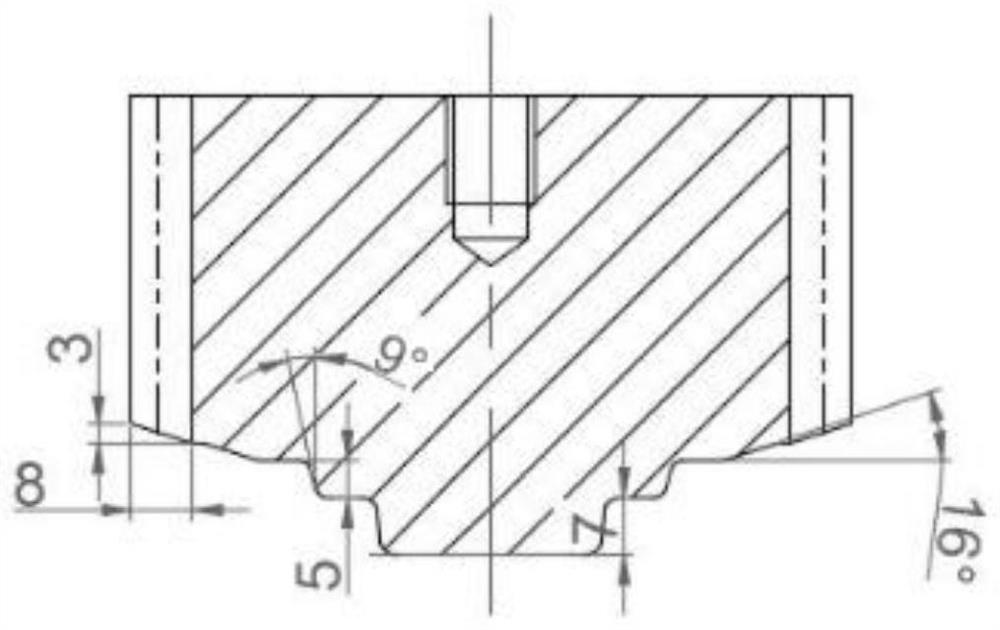

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the upper and lower corners of the pre-forged gear blank obtained in step 3 are not completely filled, and the upper and lower end faces are prefabricated with diversion areas. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com