An electrical automatic blanking device

An electrical automation, cutting technology, applied in loading/unloading, transportation and packaging, chemical instruments and methods, etc., can solve problems such as deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

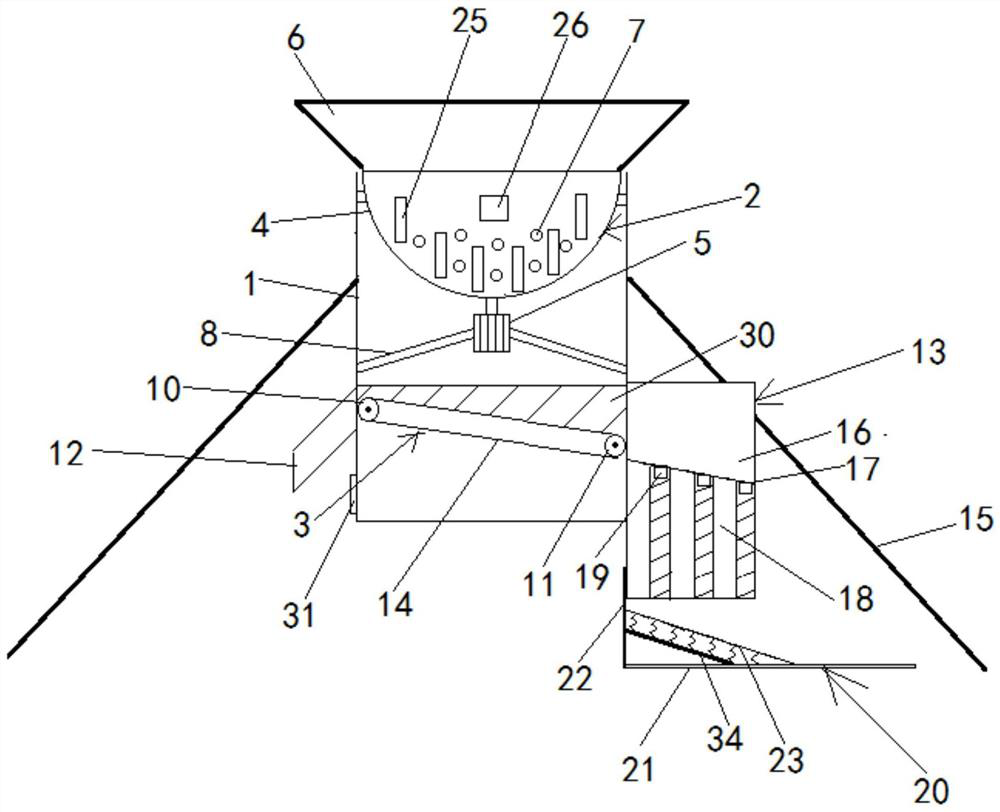

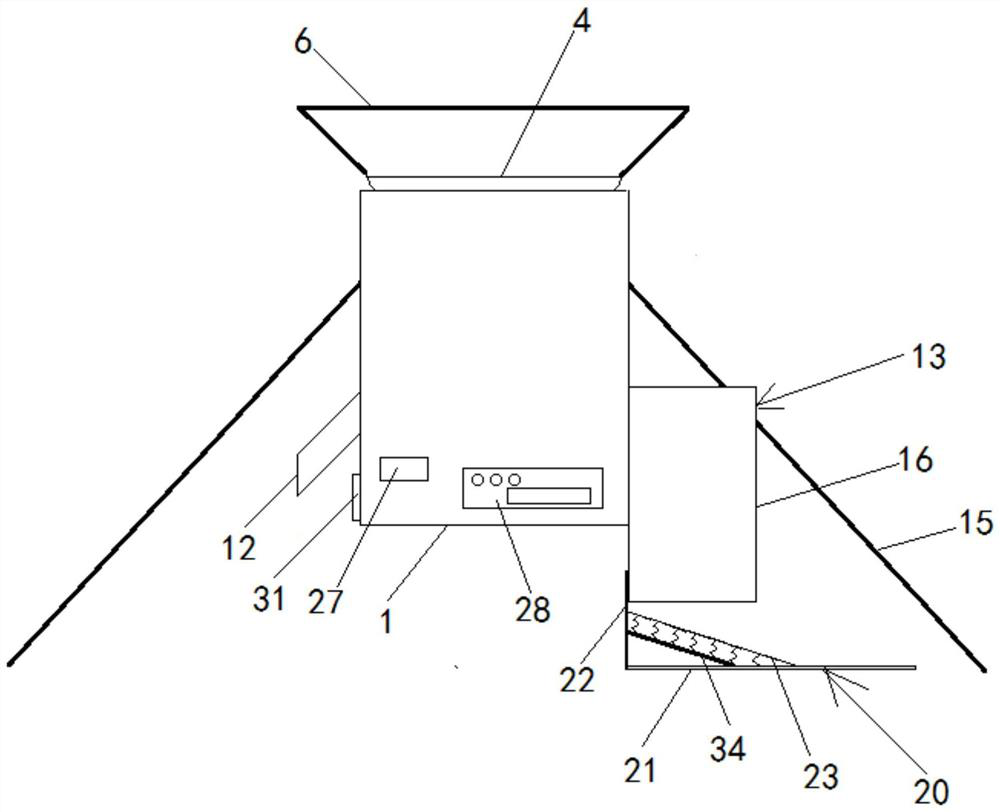

[0030] Below in conjunction with accompanying drawing in the embodiment of the present invention, for preferred embodiment and accompanying drawing Figure 1-6 With detailed instructions.

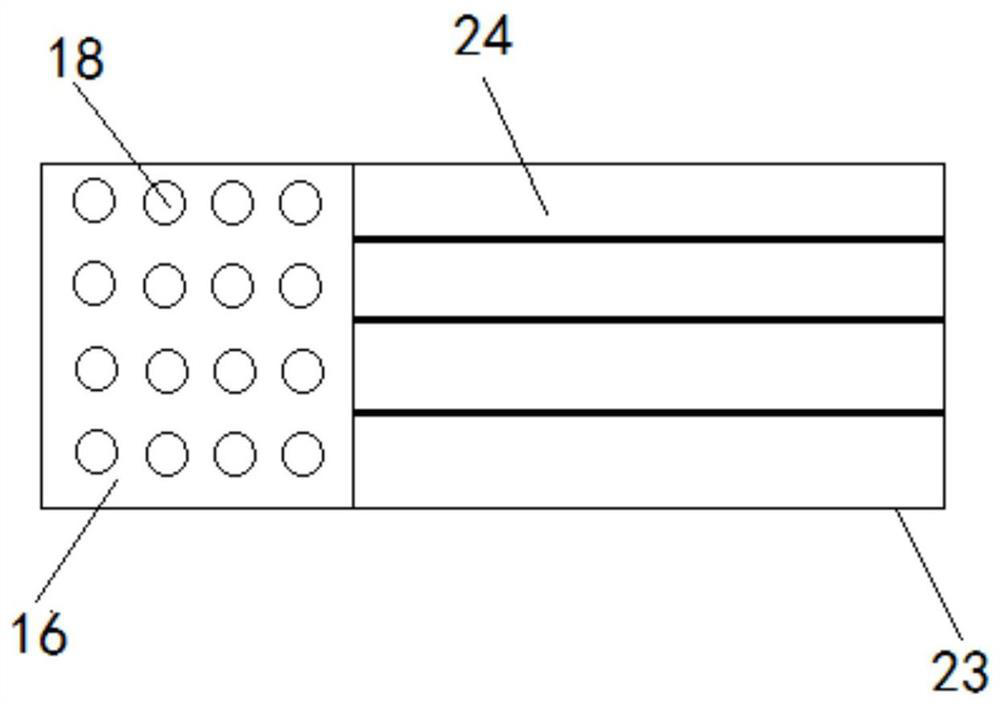

[0031] A kind of electrical automation blanking device, such as figure 1 As shown, it includes the lower material cylinder 1, the auxiliary granulation assembly 2 and the screening assembly 3. The auxiliary granulation assembly 2 is installed in the lower material cylinder 1, and the auxiliary granulation assembly 2 is arranged in the lower material cylinder 1 below the auxiliary granulation assembly 2. The screening component 3 and the auxiliary granulation component 2 are used to granulate the deformed wet spherical particles again, so that the deformed wet spherical particles can be rounded again, and the screening component 3 is used to combine the round spherical particles with auxiliary materials and deformed spherical particles Particles are separated, and the side wall of the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com