A bismuth sodium titanate-based solid-state phase-change refrigeration material and its application

A technology of solid-state phase change and sodium bismuth titanate, which is applied in the direction of luminescent materials, heat exchange materials, sustainable manufacturing/processing, etc., can solve the problems of high driving electric field and electric breakdown of electric card effect refrigeration technology, etc. Achieve the effects of low driving electric field, environmental friendliness and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

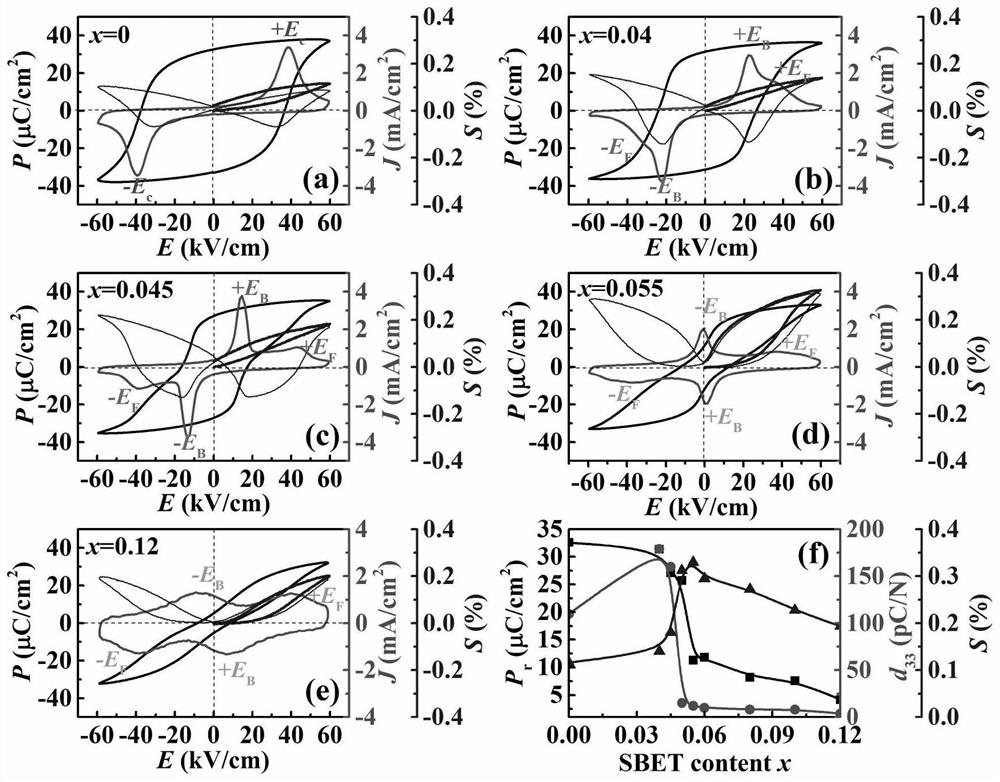

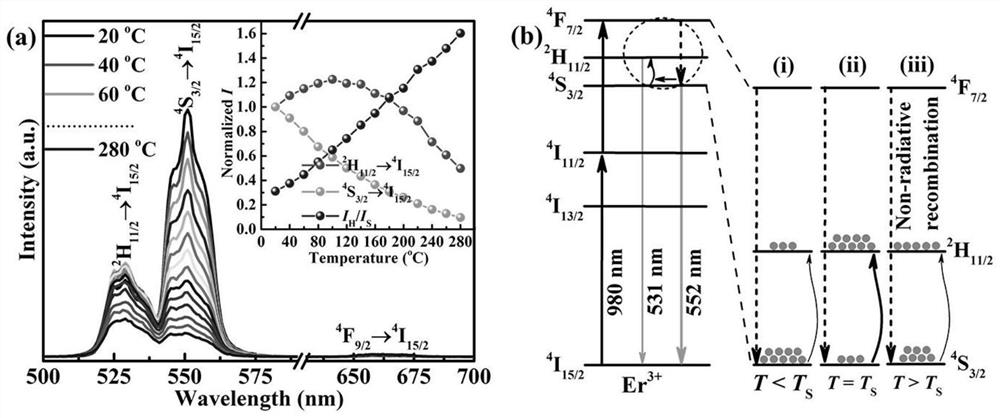

[0032] Select eigenvalues y=0.06, α=0.1, β=0.18, γ=0.02 to get (0.94-x)Bi 0.5 Na 0.5 TiO 3 -0.06BaTiO 3 -xSr 0.7 □ 0.1 Bi 0.18 Er 0.02 TiO 3 Ceramic material.

[0033] figure 1 (a)-(e) is (0.94-x)Bi 0.5 Na 0.5 TiO 3 -0.06BaTiO 3 -xSr 0.7 □ 0.1 Bi 0.18 Er 0.02 TiO 3 The P-E, J-E, and S-E loops of ceramic materials show that the x=0 component presents a saturated P-E curve, accompanied by two domain wall switching current J(E) peaks and a butterfly-shaped S-E curve, which has typical ferroelectric characteristics. When the SBET solid solution amount reaches 0.04, the material presents a pinned P-E loop, accompanied by ±E B at two strong J(E) peaks and at ±E F There are two shoulder J(E) peaks. In addition, the material also presents a large negative strain butterfly-shaped S-E curve and the highest d 33 =175pC / N( figure 1 f), which is a typical quasi-isomorphic phase boundary ferroelectric behavior. When the SBET solid solution content is further incre...

Embodiment 2

[0035] Select eigenvalues x=0.055, y=0.06, α=0.1, β=0.18, γ=0.02 to get 0.885Bi 0.5 Na 0.5 TiO 3 -0.06BaTiO 3 -0.055Sr 0.7 □ 0.1 Bi 0.18 Er 0.02 TiO 3 Ceramic material.

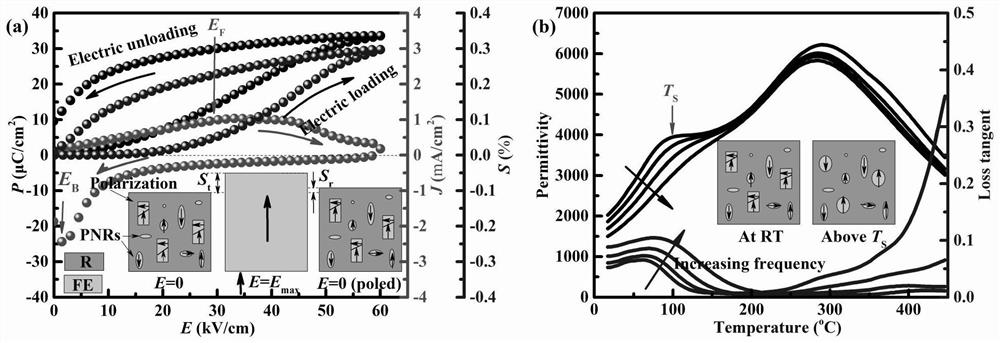

[0036] figure 2 a is 0.885Bi 0.5 Na 0.5 TiO 3 -0.06BaTiO 3 -0.055Sr 0.7 □ 0.1 Bi 0.18 Er 0.02 TiO 3 The unidirectional P-E, J-E, and S-E curves of ceramic materials, the large strain behavior of the material can be explained by the model diagram of the phase transition evolution with the electric field in the inset (a): at a low electric field 15kV / cm is applied, polar nano-regions (PNRs) in the R matrix nucleate and aggregate, resulting in a gradual increase in strain; when loaded A sufficiently high electric field E F At ≈30kV / cm, the FE phase acts as a seed core to induce the PNRs to transform into a long-range ordered FE phase, thereby generating large strains.

[0037] figure 2 b is 0.885Bi 0.5 Na 0.5 TiO 3 -0.06BaTiO 3 -0.055Sr 0.7 □ 0.1 Bi 0.18 Er 0.02 TiO 3 Dielectric th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com