Piezoelectricity, high electrostrain lead-free piezoelectric ceramic material and preparation method thereof

A lead-free piezoelectric and electrostrain technology, which is applied in the field of lead-free piezoelectric materials, can solve problems such as difficult industrialization, high cost, and complicated preparation methods of textured processes, and achieve good piezoelectric performance and temperature stability properties, wide sintering temperature range, and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to (1-x)(K 0.5 Na 0.5 ) 0.98 Ag 0.02 (Nb 0.96 Sb 0.04 )O 3 -x(Bi 0.5 Na 0.5 ) ZrO 3 The stoichiometric ratio of Na, K, Ag, Nb, Sb, Bi and Zr elements in the medium is accurately weighed, and the raw material is Na 2 CO 3 、K 2 CO 3 、Ag 2 O, Nb 2 o 5 , Sb 2 o 3 、Bi 2 o 3 and ZrO 2 , Mix the weighed raw materials by ball milling, pre-calcining, secondary ball milling, add binder, form and discharge sticky. Wherein, ball milling is used for mixing, specifically, anhydrous ethanol is used as a ball milling medium, and the mass of zirconia balls is 1.5 times of the total weight of the powder, and ball milling is performed for 24 hours. The heating program for pre-burning is to rise from room temperature to 850° C. and keep warm for 6 hours at a heating rate of 3 degrees per minute. The secondary ball milling specifically uses absolute ethanol as the medium, the mass of the zirconia balls is 1.5 times the total mass of the powder, and the ball mi...

Embodiment 2

[0035] The sample prepared in Example 1 was sintered in a two-step sintering manner, and the sintering temperature of each component was optimized. (1-x)(K 0.5 Na 0.5 ) 0.98 Ag 0.02 (Nb 0.96 Sb 0.04 )O 3 -x(Bi 0.5 Na 0.5 ) ZrO 3 , x=0.04 The optimal sintering condition for ceramics is to raise the temperature to 900°C at a rate of 5°C / min, then to 1190°C at a rate of 3°C / min, and then rapidly drop to 10°C / min. 1090°C, then keep warm for 3 hours.

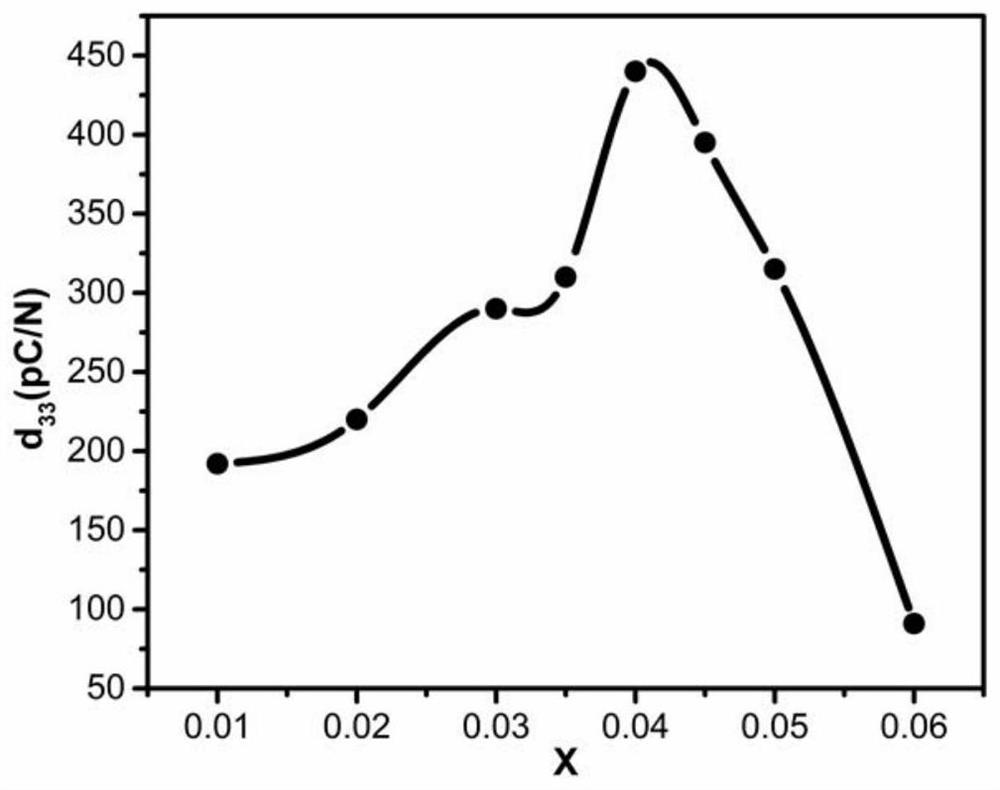

[0036] figure 1 is the d of the lead-free piezoelectric ceramic material prepared in Example 2 33 Trend chart, from the figure we can see that (1-x)(K 0.5 Na 0.5 ) 0.98 Ag 0.02 (Nb 0.96 Sb 0.04 )O 3 -x(Bi 0.5 Na 0.5 ) ZrO 3 , x = 0.04 ceramic d 33 Up to 440pC / N, which is superior to most other KNN-based ceramics.

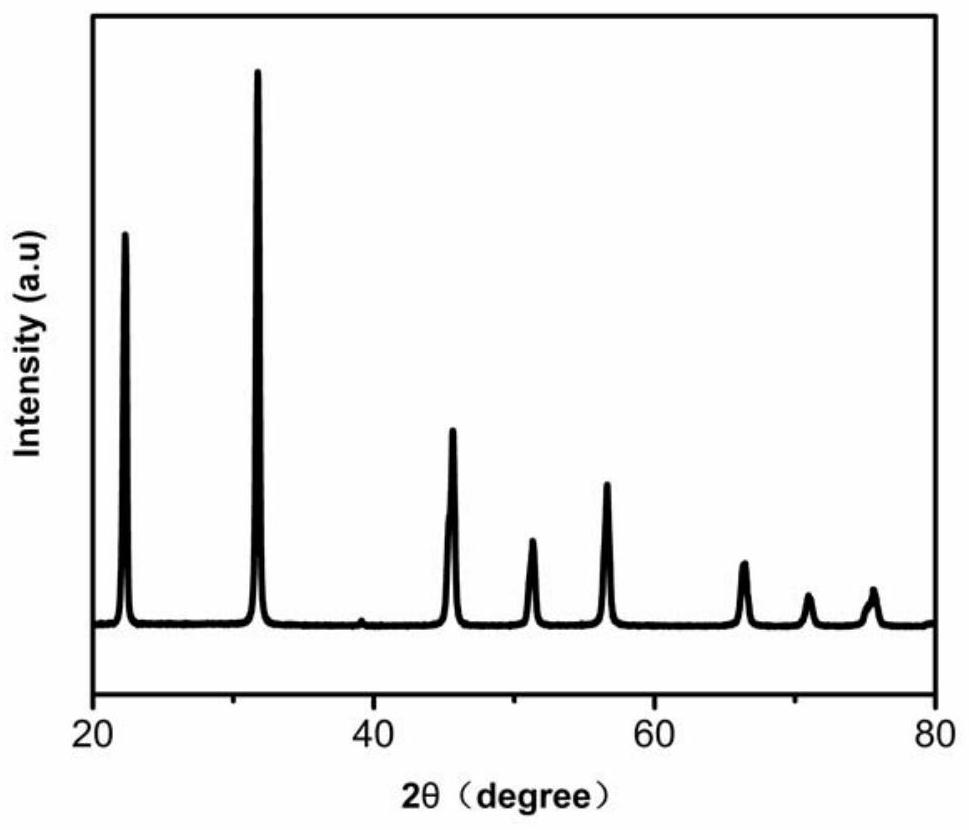

[0037] figure 2 is the XRD spectrum of the lead-free piezoelectric ceramic material prepared in Example 2. It can be seen from the figure that (1-x)(K 0.5 Na 0.5 ) 0.98 Ag 0.02 (Nb 0.96 Sb 0...

Embodiment 3

[0043] Piezoelectricity, high electrostrain lead-free piezoelectric ceramic material, the chemical composition of the material conforms to the general chemical formula 0.99(K 0.5 Na 0.5 ) 0.98 Ag 0.02 (Nb 0.96 Sb 0.04 )O 3 -0.01 (Bi 0.5 Na 0.5 ) ZrO 3 , the above materials were prepared by the following method:

[0044] (1) Using Na 2 CO 3 、K 2 CO 3 、Ag 2 O, Nb 2 o 5 , Sb 2 o 3 、Bi 2 o 3 and ZrO 2 As raw materials, weigh the above components according to the stoichiometric ratio of Na, K, Ag, Nb, Sb, Bi and Zr elements in the formula, and then sequentially undergo ball milling, pre-calcination, and secondary ball milling, and add polyvinyl alcohol as a binder , molding, and debonding procedures, wherein, during ball milling and secondary ball milling, absolute ethanol is used as the ball milling medium, the quality of zirconia balls is 1.5 times the total weight of the powder, ball milling is 24 hours, and pre-calcination is carried out at 3°C / The heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com