A kind of barium titanate lead-free piezoelectric ceramic with high temperature stability and preparation method thereof

A lead-free piezoelectric and barium titanate technology, which is applied in the field of piezoelectric ceramics, can solve problems such as large hysteresis, poor piezoelectric performance, and poor temperature stability, and achieve large electrical strain, excellent piezoelectric performance, and improved piezoelectric performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

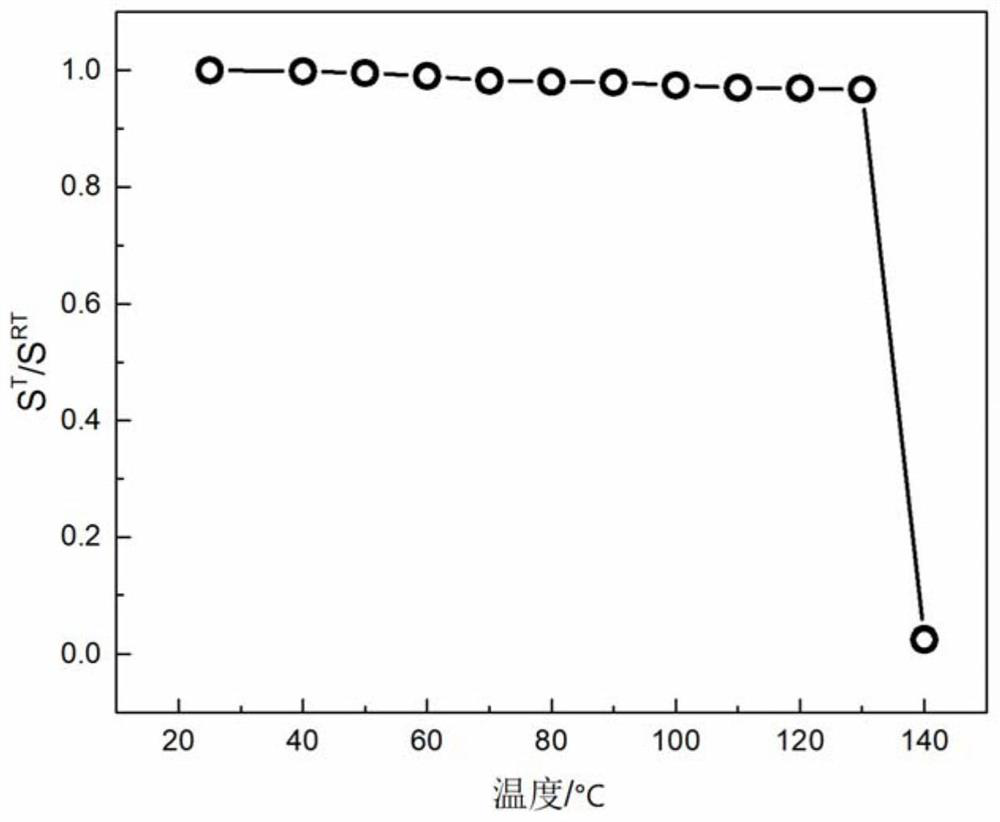

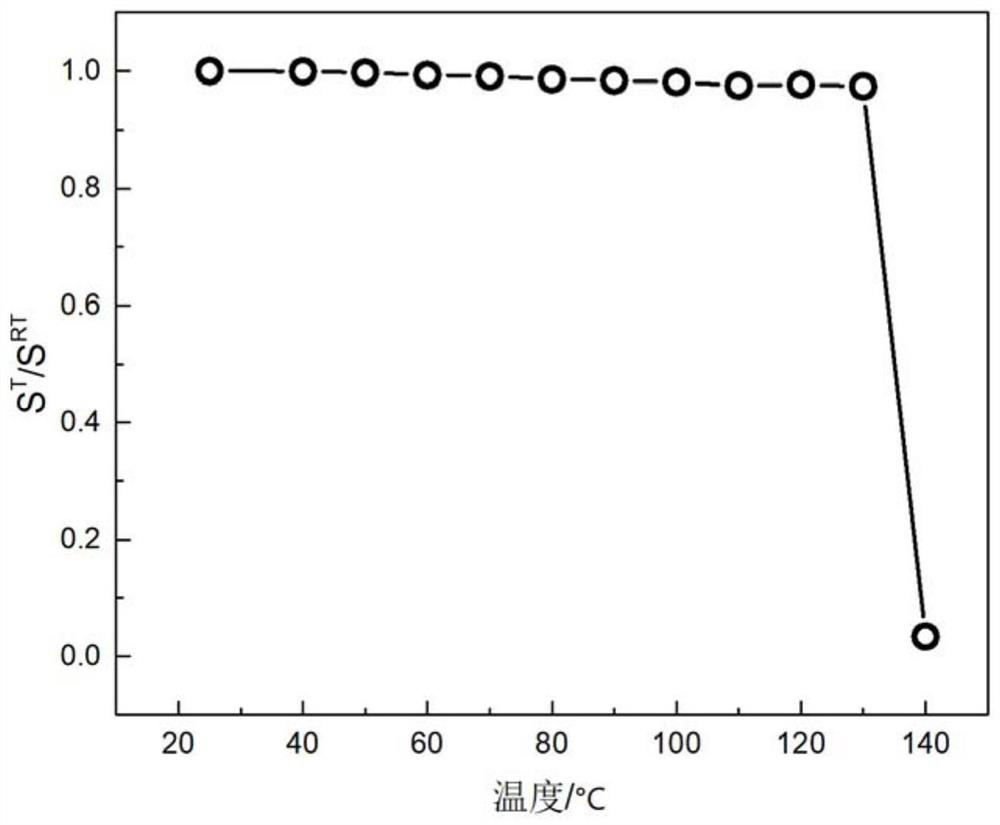

[0023] Specific Embodiment 1: The general structural formula of the barium titanate lead-free piezoelectric ceramic with high temperature stability in this embodiment is as follows:

[0024] Ba 1-x (Li 0.5 ,B 0.5 ) x TiO 3 , where 0.001≤x≤0.1.

specific Embodiment approach 2

[0025] Specific embodiment two: the preparation method of barium titanate lead-free piezoelectric ceramics with high temperature stability in this embodiment includes the following steps:

[0026] 1. Weighing ingredients: mix barium carbonate, lithium carbonate, boron oxide and titanium oxide raw material powder according to the general formula Ba 1-x (Li 0.5 ,B 0.5 ) x TiO 3 The stoichiometric ratio is weighed, where 0.001≤x≤0.1;

[0027] Lithium ions and boron ions in the raw materials of this embodiment are easy to form defect complexes in the form of ion pairs in the ceramics due to their smaller ionic radii and greater electronegativity, and the ion pairs cause local lattice distortion in the structure. This kind of local lattice distortion makes it easier to flip the polarization direction, which is of great help to improve the piezoelectric performance of ceramics. At the same time, the self-built electric field generated by ion pairs inhibits the generation of rev...

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment is different from Embodiment 2 in that: in step 2, the ball milling time is 10-14 hours, the drying temperature is 50-120° C., and the drying time is 10-14 hours. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com