Elastic material and production method and application thereof

An elastic material and polymerization reaction technology, applied in the field of elastic materials, can solve the problems of high power consumption, limited functions, inconvenient medical applications, etc., and achieve the effect of enhancing mechanical properties and piezoelectric properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

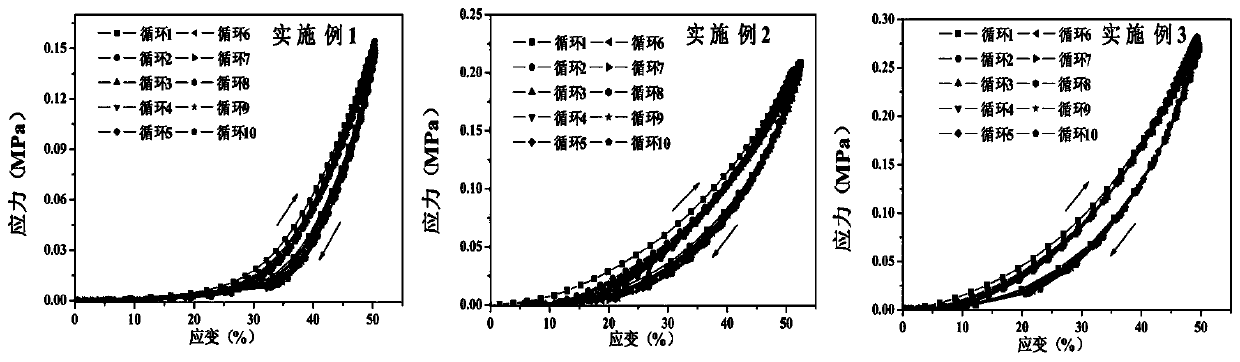

Embodiment 1

[0042]Polyvinylidene fluoride, sodium p-styrene sulfonate, acrylonitrile, crosslinking agent N, N-methylenebisacrylamide, initiator ammonium persulfate (APS) are 10:60:10:60 according to the mass ratio: 4:0.5, the solid content is 5w / v%, dissolved in DMSO in turn, N 2 Under the atmosphere, heat preservation reaction at 40° C. for 120 minutes, and then freeze-dry, the freeze-drying temperature is -80° C., and the freeze-drying time is 48 hours to obtain an elastic material.

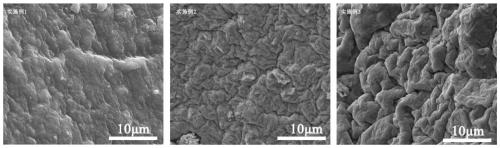

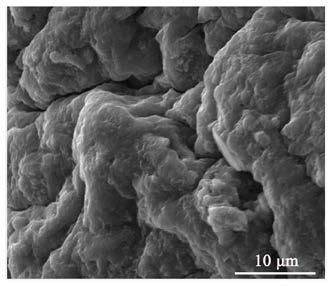

[0043] Such as figure 1 As shown, the surface of the elastic material prepared in this embodiment is wrinkled.

Embodiment 2

[0045] Polyvinylidene fluoride, sodium p-styrenesulfonate, acrylonitrile, crosslinking agent N, N-methylenebisacrylamide, initiator ammonium persulfate (APS) are 15:70:15:5 according to the mass ratio: 0.75, the solid content is 10w / v%, dissolved in DMSO in turn, N 2 Under the atmosphere, heat preservation reaction at 50° C. for 150 minutes, and then freeze-dry, the freeze-drying temperature is -50° C., and the freeze-drying time is 52 hours to obtain an elastic material.

[0046] Such as figure 1 As shown, the surface of the elastic material prepared in this example is more wrinkled than that of the elastic material in Example 1.

Embodiment 3

[0048] Polyvinylidene fluoride, sodium p-styrene sulfonate, acrylonitrile, crosslinking agent N, N-methylenebisacrylamide, initiator ammonium persulfate (APS) are 20:80:20:6 according to the mass ratio: 1, the solid content is 15w / v%, dissolved in DMSO in turn, N 2 Under the atmosphere, heat preservation reaction at 60° C. for 180 minutes, and then freeze-dry, the freeze-drying temperature is -20° C., and the freeze-drying time is 56 hours to obtain an elastic material.

[0049] Such as figure 1 As shown, the surface of the elastic material prepared in this embodiment is more wrinkled than that of the elastic material in Example 2. In Examples 1 to 3, as the content of PVDF increases, the wrinkle condition is strengthened. This wrinkle appearance is the structural basis of the high elasticity of the elastomer and provides the energy dissipation function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com