Polyvinylidene fluoride-hexafluoropropylene magnetic porous piezoelectric composite film as well as preparation method and application thereof

A polyvinylidene fluoride, composite film technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, application of piezoelectric device property force measurement, electrical components, etc., can solve the problem of seldom considering flexibility. Good copolymers, loss of nano-fillers, reduction of material flexibility, etc., to achieve the effect of improving piezoelectric output performance, increasing compressibility, and huge application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

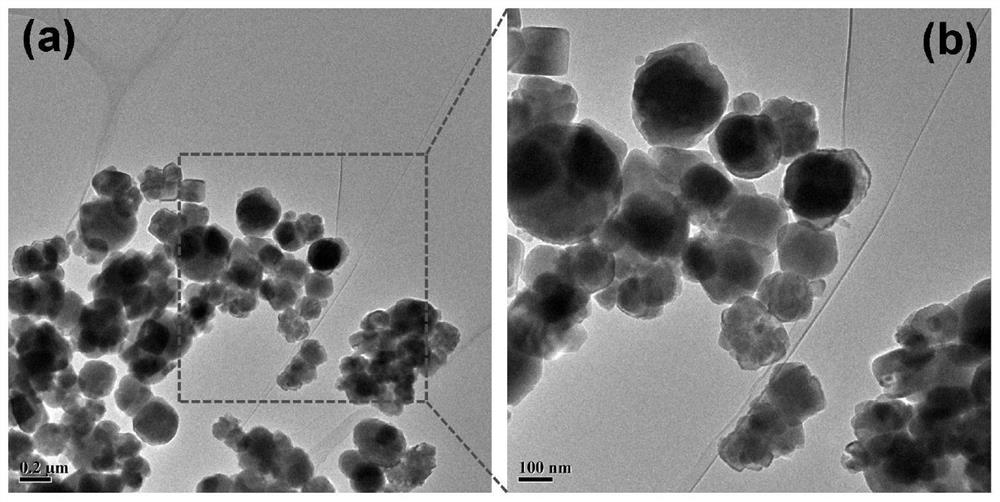

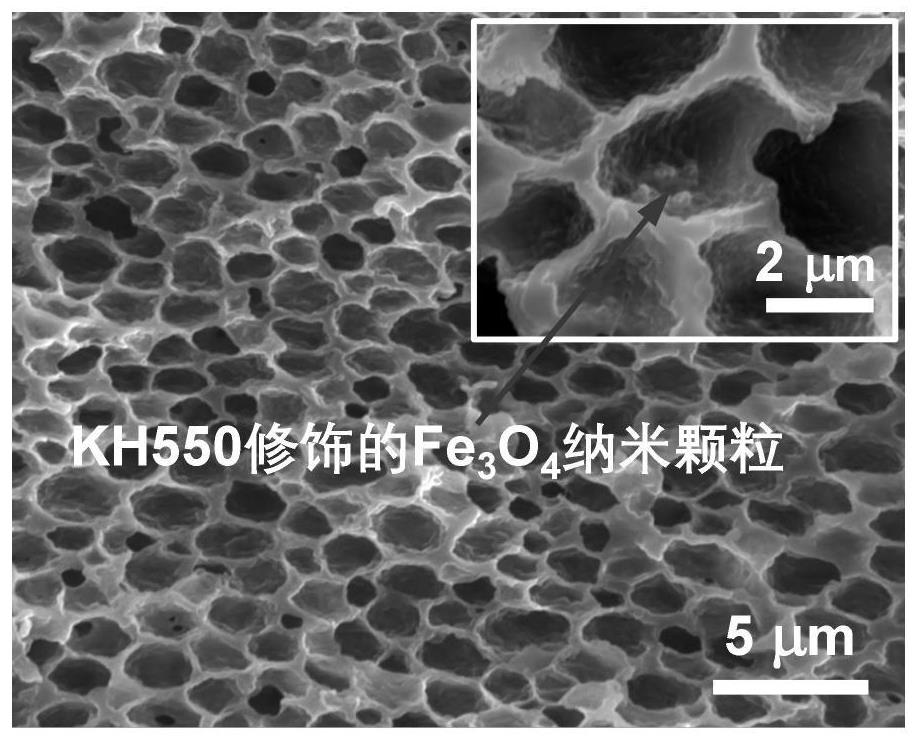

[0026] (1) 1mg Fe 3 o 4 Nanoparticles were dispersed in 10mL ethanol / deionized water mixed solution, the volume ratio of ethanol to deionized water was 1:1, under argon protection, 0.5mL KH550 was added to the above mixed solution and stirred in an oil bath at 60°C for 8h , cooled to room temperature, the KH550 modified magnetic particles were washed with deionized water until neutral, and then vacuum-dried at 60°C for 24h to obtain modified Fe 3 o 4 nanoparticles;

[0027] (2) 1g PVDF-HFP matrix is completely dissolved in acetone, and the modified Fe obtained in step (1) 3 o 4 The nanoparticles were ultrasonically dispersed in acetone, and then mixed with the matrix solution, in which Fe 3 o 4 The mass ratio to PVDF-HFP is 0.1:100;

[0028] (3) Add 0.5g PEG-800 additive to the above mixed solution, and then stir the mixed solution vigorously for 2 hours to achieve uniform dispersion of filler particles. After cooling to room temperature, depressurize the obtained sol...

Embodiment 2

[0033] (1) 20mg Fe 3 o 4 Nanoparticles were dispersed in 50mL ethanol / deionized water mixed solution, the volume ratio of ethanol to deionized water was 2:1, under argon protection, 10mL KH550 was added to the above mixed solution and stirred in an oil bath at 80°C for 4h, After cooling to room temperature, the KH550-modified magnetic particles were washed with deionized water until neutral, and then vacuum-dried at 80 °C for 12 h to obtain modified Fe 3 o 4 nanoparticles;

[0034] (2) 2g PVDF-HFP matrix is completely dissolved in acetone, and the modified Fe obtained in step (1) 3 o 4 The nanoparticles were ultrasonically dispersed in acetone, and then mixed with the matrix solution, in which Fe 3 o 4 The mass ratio to PVDF-HFP is 1:100;

[0035] (3) Add 2g of PEG-800 additive to the above mixed solution, and then stir the mixed solution vigorously for 3 hours to achieve uniform dispersion of filler particles. The scraper film is cast on the board, and the height of...

Embodiment 3

[0040] (1) 50mg Fe 3 o 4 Nanoparticles were dispersed in 120mL ethanol / deionized water mixed solution, the volume ratio of ethanol to deionized water was 1.5:1, under argon protection, 20mL KH550 was added to the above mixed solution and stirred in 70°C oil bath for 5h, After cooling to room temperature, the KH550 modified magnetic particles were washed with deionized water to neutrality, and then vacuum-dried at 60°C for 24 hours to obtain modified Fe 3 o 4 nanoparticles;

[0041] (2) 1g PVDF-HFP matrix is completely dissolved in acetone, and the modified Fe obtained in step (1) 3 o 4 The nanoparticles were ultrasonically dispersed in acetone, and then mixed with the matrix solution, in which Fe 3 o 4 The mass ratio to PVDF-HFP is 5:100;

[0042] (3) Add the additive 2g PEG-800 to the above mixed solution, and then stir the mixed solution vigorously for 2 hours to realize the uniform dispersion of filler particles. The scraper film is cast on the board, and the heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com