High-purity indium preparation device

A preparation device and high-purity technology, which are applied to the improvement of process efficiency, photography process, instruments, etc., can solve the problems of high process control difficulty, harsh production environment, large fluctuation of product quality, etc., and achieve clean air and stable product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

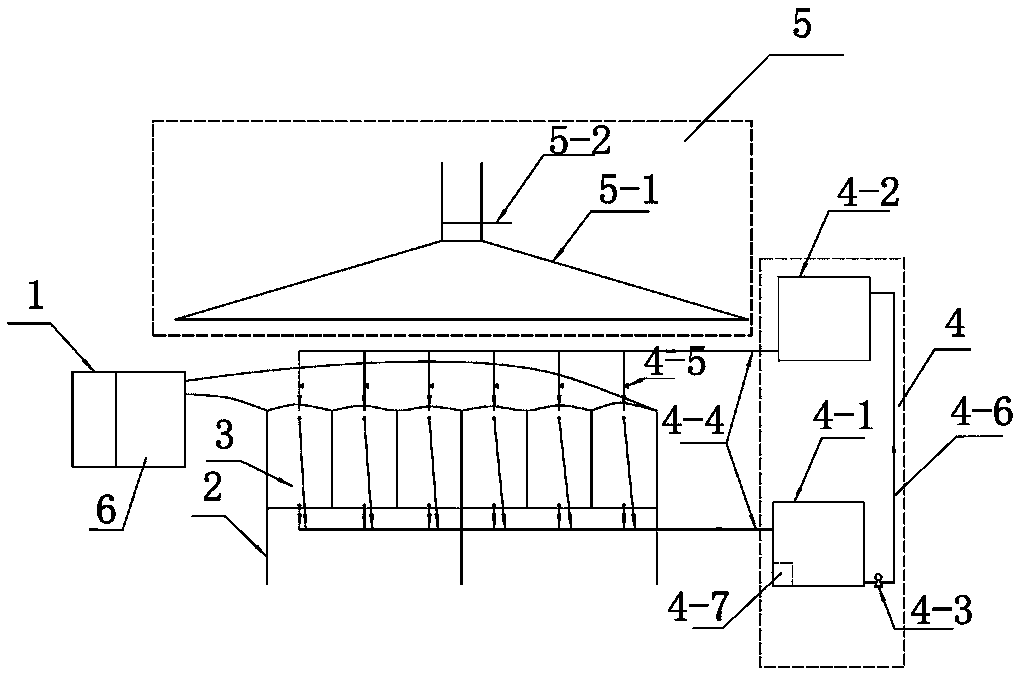

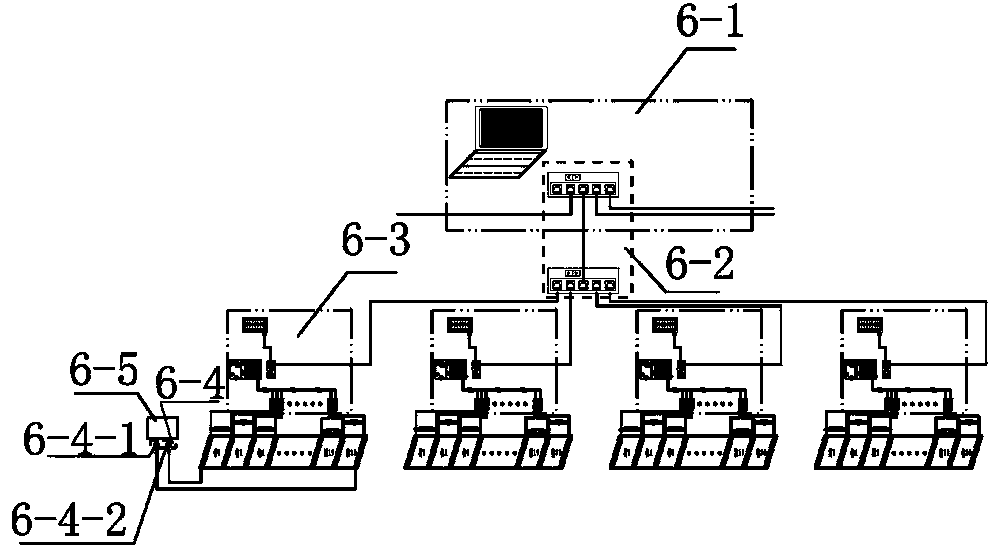

[0017] figure 1 The high-purity indium preparation device shown includes an electrolytic cell support 2, six electrolytic cells 3 are arranged on the electrolytic cell support 2, and an electrolytic circulation system 4 is provided at one end of the electrolytic cell 3, and the electrolytic circulation system 4 is connected to the electrolytic cell 3 , the electrolytic circulation system 4 is equipped with PH detection sensors 4-7; the other end of the electrolytic cell 3 is equipped with an electrical control and monitoring system 6 and a power supply unit 1, and the power supply unit 1 is an IGBT DC power supply with constant voltage / constant current dual mode Output and remote intelligent control functions, control and display accuracy ≥ 0.1V / A; electrical control and monitoring system 6 and power supply unit 1 are electrically connected to the electrolytic cell 3, and a gas collection unit 5 is arranged above the electrolytic cell 3.

[0018] The electrolytic circulation s...

Embodiment 2

[0028] In this embodiment, the power supply unit 1 is a silicon rectified DC power supply, and the circulation mode of the electrolytic circulation system 4 is the up-in and down-out type. In this mode, the flow direction of a part of the electrolyte is consistent with the sedimentation direction of impurities such as anode slime, which is beneficial to the sedimentation of the anode slime. Prevent the anode slime from adhering to the cathode, and the temperature distribution of the electrolyte is relatively uniform, which is beneficial to reduce the impact of suspended impurities in the electrolyte on the quality of the cathode product. Part of the electrolyte flows in parallel from the top of the electrolytic cell 3, and the floating objects on the surface of the electrolyte are taken out of the cell in time, which is beneficial to the self-cleaning of the electrolyte. All the other working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com