Method for removing blockage, increasing permeability and well-completing of horizontal well of coalbed methane

A technology for coalbed methane and horizontal wells, which is applied to the fields of penetration enhancement and completion and plugging removal of horizontal wells of coalbed methane, can solve problems such as low extraction efficiency and blockage of pore walls, and achieves increased production and productivity, improved desorption, and inhibited resorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

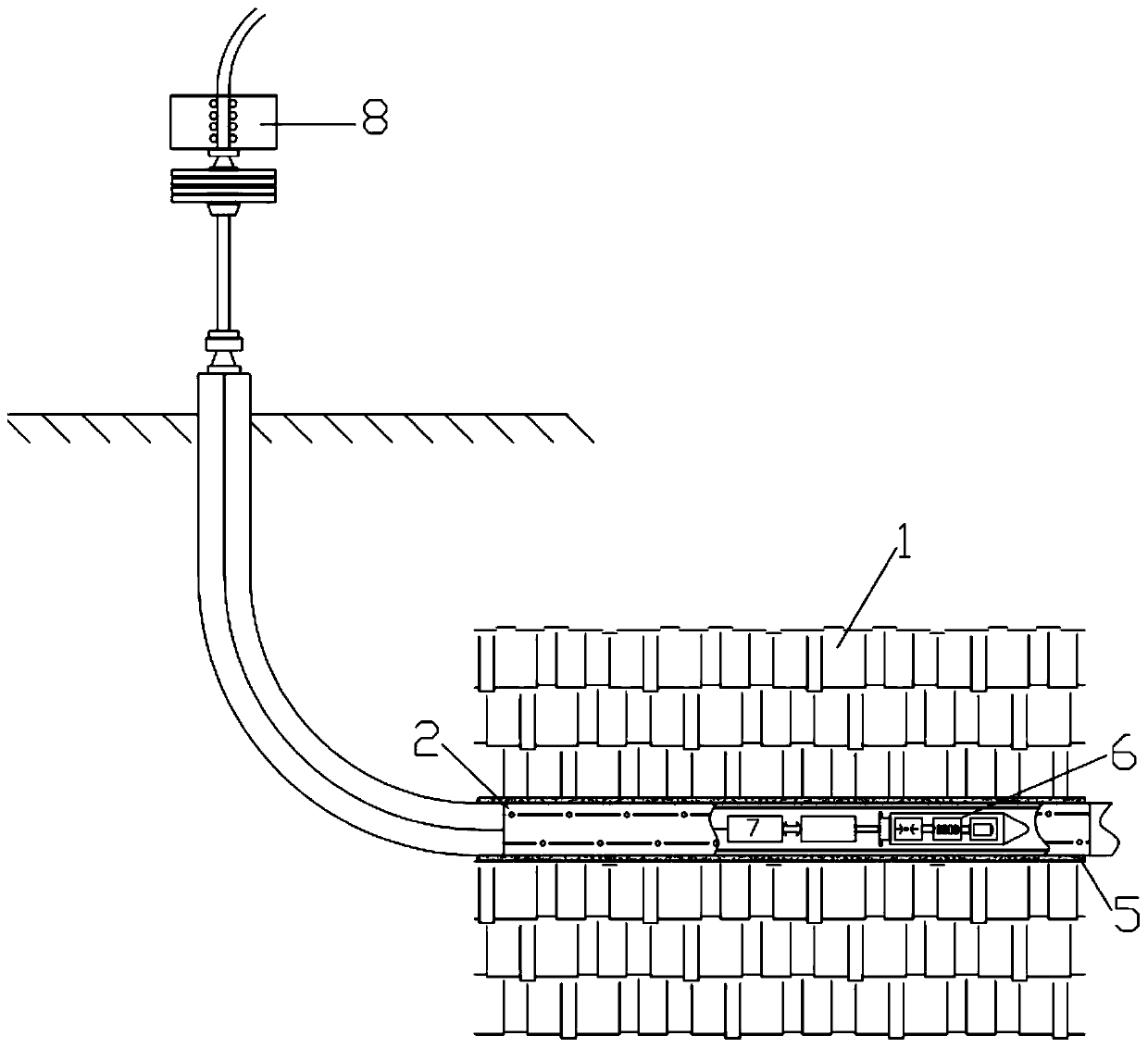

[0031] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

[0032] like Figure 1 to Figure 5 As shown, the coalbed methane horizontal well plugging removal and anti-permeability completion method includes the following steps:

[0033] S1, drilling and using mud cementing;

[0034] In the process of drilling, in order to ensure the stability of the well wall and well completion, the well wall can be reinforced with mud.

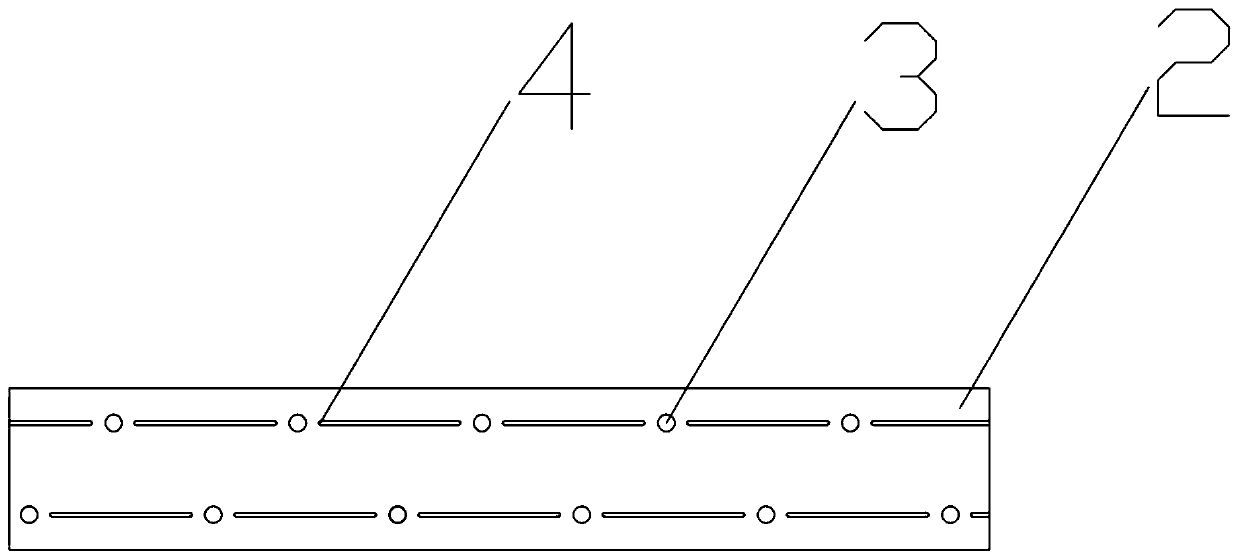

[0035] S2, run into the screen pipe 2 after the well is completed;

[0036] Run the screen 2 into the horizontal well, and fix the screen 2 in the well to support the well wall;

[0037] The lowered screen pipe 2 can also be selected as a casing, and the perforation on the lowered casing pipe can play the same role as the screen pipe 2 .

[0038] S3, according to the effective action distance of the controllable shock wave equipment 6 in the target coal seam 1, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com