State-sixth-stage SCR front-end urea mixing structure

A technology of mixed structure and urea, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of complex mixed structure and high requirements for anti-urea crystallization, and achieve uniform airflow distribution, less crystallization risk, and longer distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

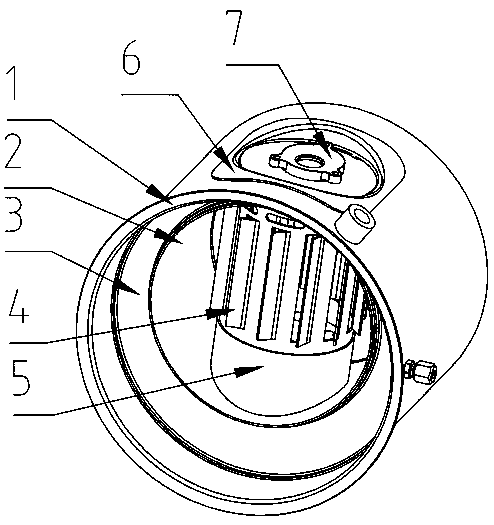

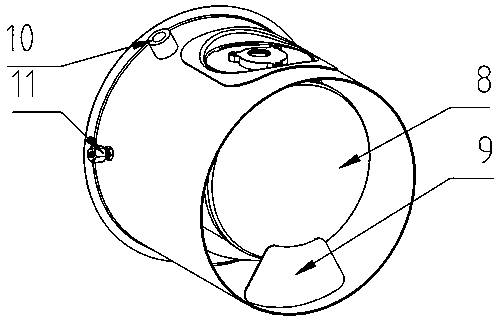

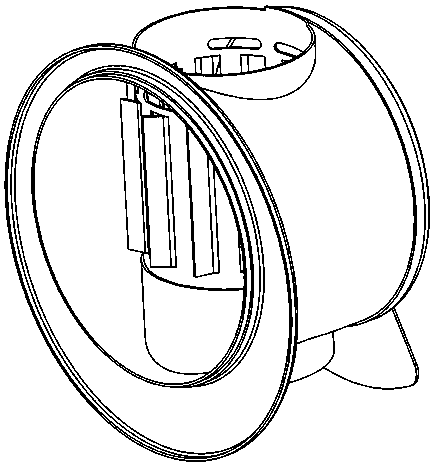

[0018] Such as figure 1 and figure 2 As shown, the present invention is a national six SCR front-end urea mixing structure, including bell mouth cylinder 1, inner cylinder 2, front partition 3, swirl vane tube 4, stainless steel winding net 5, nozzle seat support base 6 , Nozzle seat 7, spherical plug 8, spoiler 9, temperature sensor base 10 and differential pressure sensor base 11.

[0019] The bell mouth cylinder 1 covers the outer side of the heat preservation inner cylinder 2; the front partition 3 is located between the bell mouth cylinder 1 and the heat insulation inner cylinder 2, and is welded with both, and an annular cavity can be formed at this time , the annular structure can lengthen the passage of the airflow to ensure that the ammonia gas and the exhaust gas are fully mixed; it also forms an insulation layer to better ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com