System and method for active cancellation of pressure pulses

A pressure and differential pressure technology, applied in the field of gas concentration measurement and monitoring, which can solve problems such as poor measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

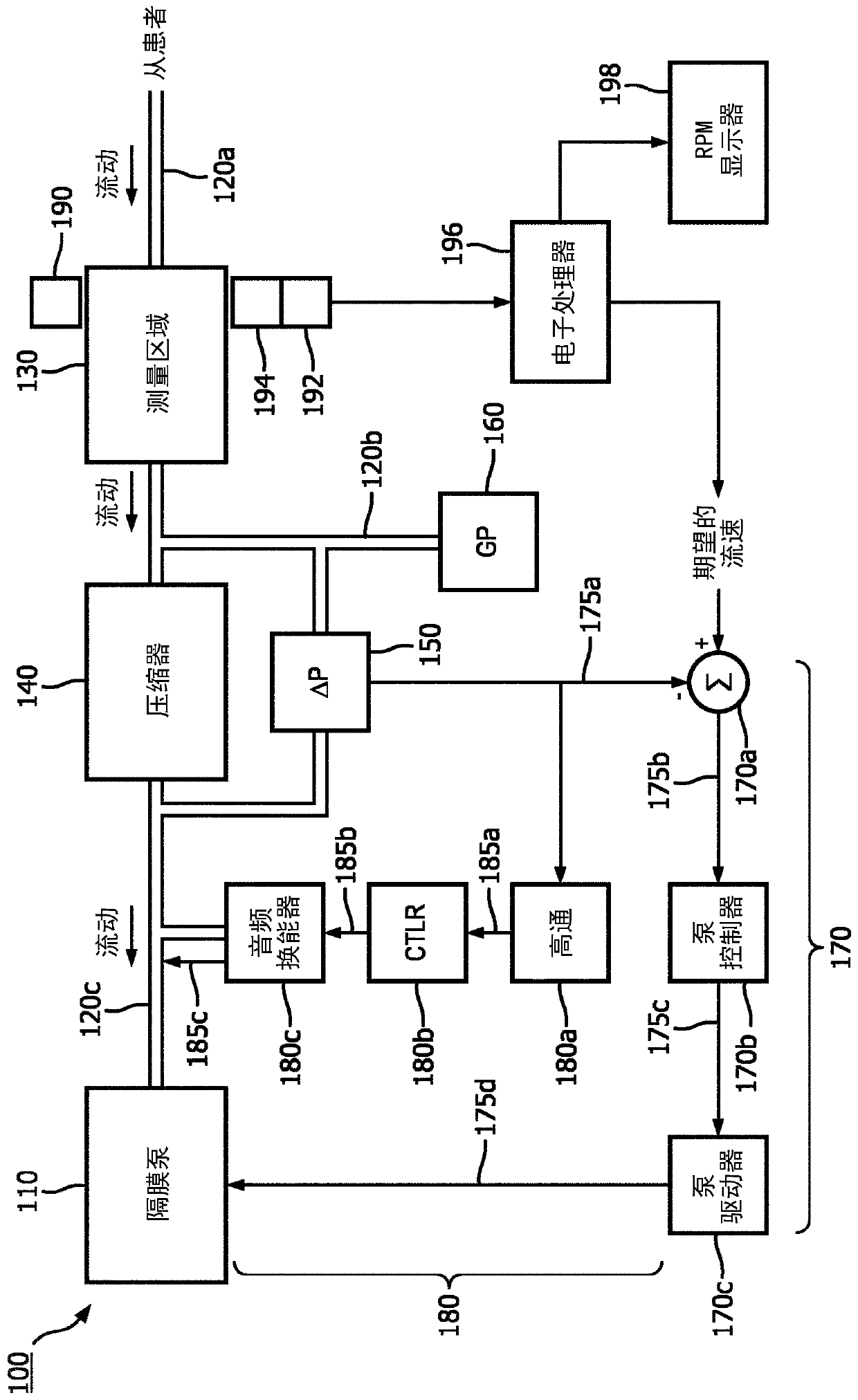

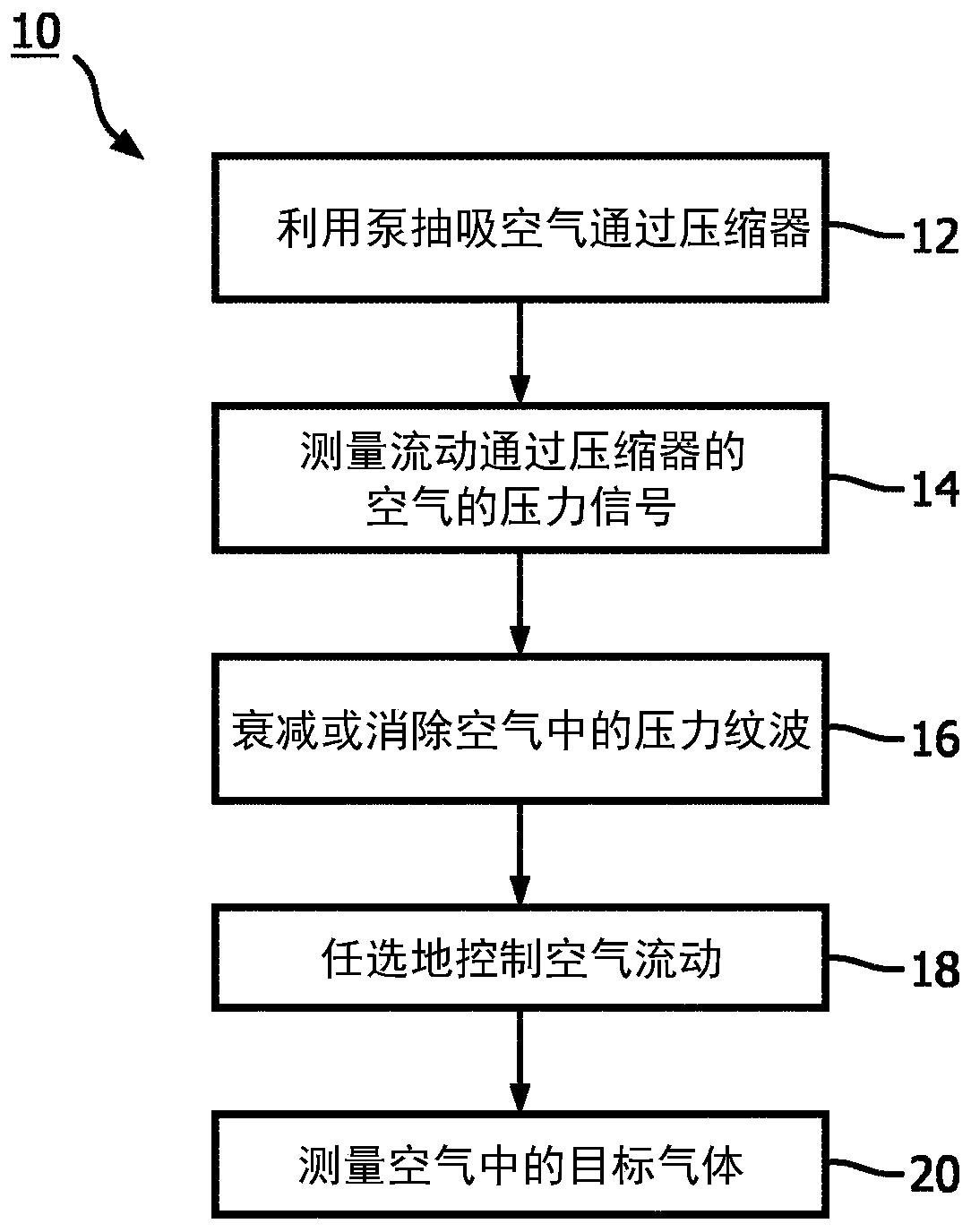

[0018] In RGM, the flow of breathing gas is usually regulated to a relatively constant rate to avoid transient distortions of the gas concentration record (ie, waveform). This flow regulation is often accomplished by introducing a compressor (such as an orifice or capillary) into the gas flow path and controlling the pump drive level to be controlled to maintain a constant pressure drop across the compressor. Since pressure drop is a direct function of flow rate, maintaining a constant pressure drop produces a constant flow rate. However, in the case of pump-induced pressure pulsations, the magnitude of the pulsations in the pressure drop can be large and can even exceed the magnitude of the flow-induced pressure drop, which can be problematic for the accuracy of flow rate measurement and control.

[0019] Another problem potentially introduced by pressure pulsations in the sample line is that pressure pulsations appear on the gas sample in the measurement region of the RGM. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com