Vehicle middle channel intelligent welding method and workstation

A welding method and workstation technology, applied to welding equipment, welding equipment, laser welding equipment, etc., can solve the problems of increasing materials, labor costs, and large floor space, so as to shorten the clamping time, improve work efficiency, and avoid accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

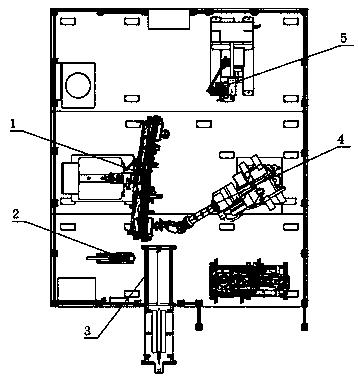

[0020] Workstation of the present invention, its preferred embodiment is:

[0021] Including projection welding machine 1, laser marking machine 2, material receiving rack 3, robot gripper 4, spot welding machine 5, circulating water circuit system and control box; the control box controls each module of the entire workstation to work; projection welding machine 1 , the receiving rack 3 and the spot welding machine 5 are distributed around the robot gripper 4; the laser marking machine 2 is located on one side of the receiving rack 3;

[0022] The present invention uses the above-mentioned workstation to realize the intelligent welding method for the middle channel of the automobile, and its preferred specific implementation mode is:

[0023] A. The operator places the objects in the middle channel to be processed in the waiting area of the workstation, presses the start button of the control box, and each station is in the waiting stage;

[0024] B. The robot gripper 4 pic...

specific Embodiment

[0028] For specific examples, see figure 1 , the workstation of the present invention includes a projection welding machine 1, a laser marking machine 2, a material receiving rack 3, a robot gripper 4, a spot welding machine 5, a circulating water loop system and a control box; the control box controls each module of the entire workstation to carry out Work; the projection welding machine 1, the receiving rack 3 and the spot welding machine 5 are distributed around the robot gripper 4; the laser marking machine 2 is located on one side of the receiving rack 3;

[0029] Specifically, each branch of the circulating water circuit system is distributed at the projection welding machine 1, the material receiving rack 3 and the spot welding machine 5, which respectively cool the passages and equipment in the car at each station to ensure safe production.

[0030] Specifically, the control box has a built-in PLC, and the workstation is precisely controlled by the PLC.

[0031] Speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com