A kind of conductive heat conduction wear-resistant PVC pipe and preparation method thereof

A PVC pipe, electrical and heat conduction technology, applied in the field of polymer materials, can solve the problems of difficult composite materials, such as electrical conduction, heat conduction and wear resistance, can not improve the dispersion of fillers well, and the density of fillers is high, so as to achieve improved dispersion and good electrical conductivity , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

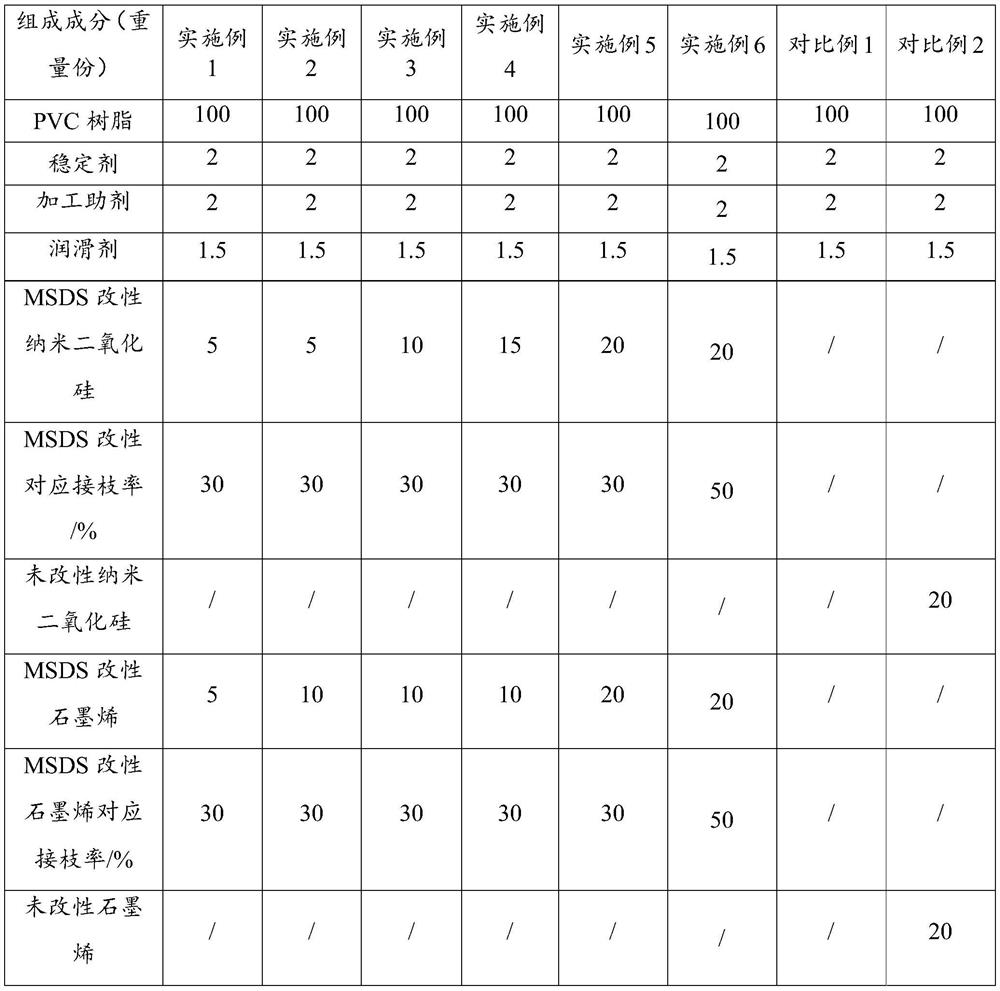

[0025] The composition of the conductive, thermally conductive and wear-resistant PVC pipes of Examples 1-6 is shown in Table 1, wherein, the preparation method of the conductive, thermally conductive and wear-resistant PVC pipes of Examples 1-6 comprises the following steps:

[0026] (1) Put each component into the high-speed mixer in proportion and gradually heat it, and stir it fully under the condition of 1000-1200r / min until the temperature of the mixture reaches 110-120°C, then put the mixed material into the cold mixing equipment, Continue mixing under the condition of 400-500r / min until the temperature of the material drops to 40-50°C;

[0027] (2) Put the mixed material into the hopper of the extruder and extrude to prepare the PVC pipe, wherein the temperature of the extruder is: 180°C-185°C in the first zone, 180°C-185°C in the second zone 175°C-180°C in the third zone, 170°C-175°C in the fourth zone and 165°C-170°C in the fifth zone; the temperature in the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com