Method for reinforcing aluminum alloy component material by using cesium oxide modified graphene

A composite material and graphene technology, which is applied in the field of metal composite material preparation, can solve problems such as damage to the graphene crystal structure, difficulty in uniform dispersion, and weak interface bonding, so as to improve the quality of interface bonding, improve uniform dispersion, and have obvious mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

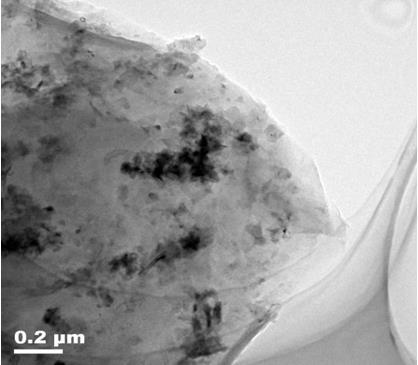

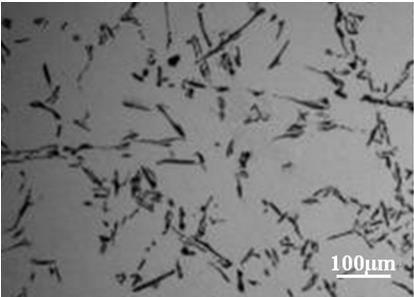

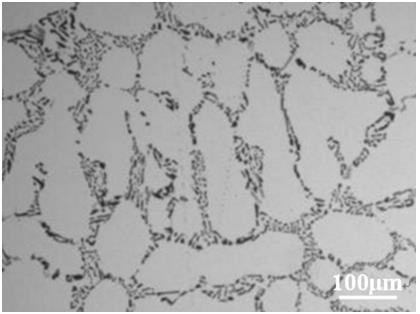

Image

Examples

Embodiment 1

[0019] (1) Cesium oxide-modified graphene pre-dispersion: According to the concentration ratio of 1.0 g / L, cesium oxide-modified graphene was added to ethanol, and a uniformly dispersed reinforcement mixture was obtained by ultrasonication for 0.5 h.

[0020] (2) According to the mass ratio of cesium oxide modified graphene to aluminum alloy powder of 5:95, aluminum alloy with a particle size of less than 325 mesh is added to the mixed solution obtained in step (1), and cesium oxide is obtained after mechanical stirring for 0.5h A mixture of modified graphene and aluminum alloy powder uniformly mixed.

[0021] (3) Filtrating the mixed solution obtained in step (2) and then vacuum-drying to obtain a composite powder uniformly mixed with cesium oxide-modified graphene and aluminum alloy powder.

[0022] (4) Use the composite powder obtained in step (3) to prepare a uniformly dispersed cesium oxide-modified graphene prefabricated block under a pressure of 100 MPa, and preheat it ...

Embodiment 2

[0028] The method for the cesium oxide modified graphene reinforced aluminum alloy composite material follows the steps below.

[0029] (1) Cesium oxide-modified graphene pre-dispersion: According to the concentration ratio of 1.0 g / L, cesium oxide-modified graphene was added to ethanol, and a uniformly dispersed reinforcement mixture was obtained by ultrasonication for 0.5 h.

[0030] (2) According to the mass ratio of cesium oxide modified graphene to aluminum alloy powder of 5:95, aluminum alloy with a particle size of less than 325 mesh is added to the mixed solution obtained in step (1), and cesium oxide is obtained after mechanical stirring for 0.5h A mixture of modified graphene and aluminum alloy powder uniformly mixed.

[0031] (3) Filtrating the mixed solution obtained in step (2) and then vacuum-drying to obtain a composite powder uniformly mixed with cesium oxide-modified graphene and aluminum alloy powder.

[0032] (4) Use the composite powder obtained in step (3...

Embodiment 3

[0038] The method for the cesium oxide modified graphene reinforced aluminum alloy composite material follows the steps below.

[0039] (1) Cesium oxide-modified graphene pre-dispersion: According to the concentration ratio of 1.0 g / L, cesium oxide-modified graphene was added to ethanol, and a uniformly dispersed reinforcement mixture was obtained by ultrasonication for 0.5 h.

[0040] (2) According to the mass ratio of cesium oxide modified graphene to aluminum alloy powder of 5:95, aluminum alloy with a particle size of less than 325 mesh is added to the mixed solution obtained in step (1), and cesium oxide is obtained after mechanical stirring for 0.5h A mixture of modified graphene and aluminum alloy powder uniformly mixed.

[0041] (3) Filtrating the mixed solution obtained in step (2) and then vacuum-drying to obtain a composite powder uniformly mixed with cesium oxide-modified graphene and aluminum alloy powder.

[0042] (4) Use the composite powder obtained in step (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com