Fully-automatic underground mining transportation system

A transportation system and fully automatic technology, applied in underground mining, underground transportation, surface mining, etc., can solve problems such as the inability to effectively improve operational efficiency and safety, reduce the probability of casualties, optimize parameter design, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

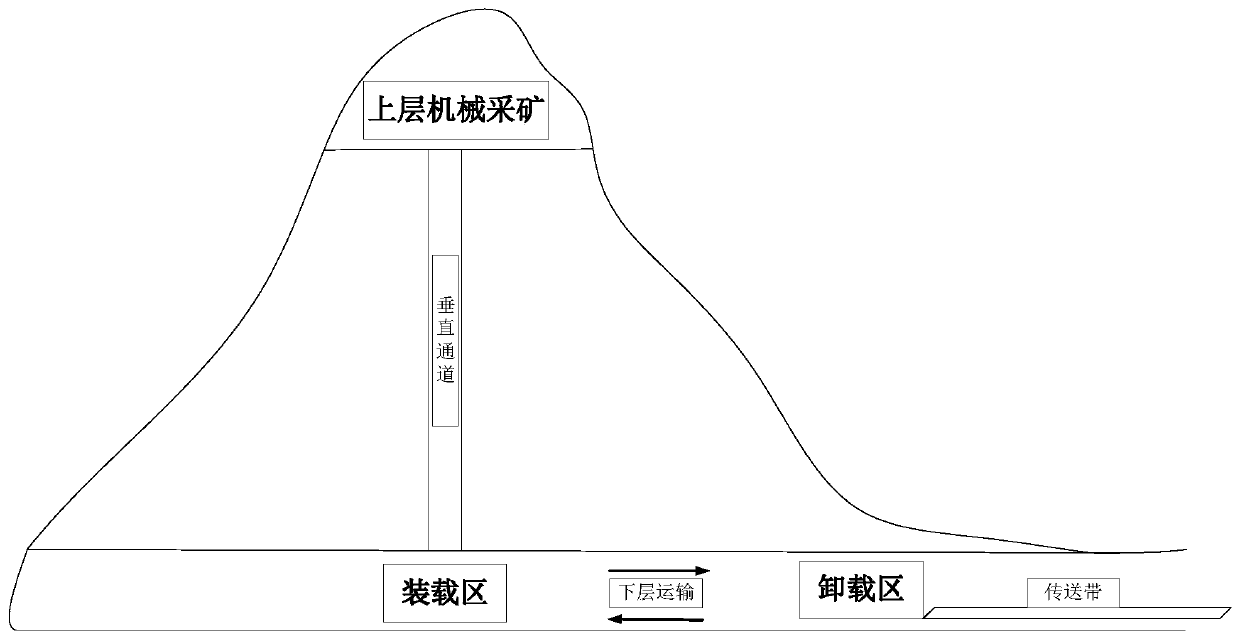

[0065] figure 1 It is a schematic diagram of a fully automatic underground mining transportation system. The mining transportation system is divided into upper and lower layers. Mining machinery is used for mining on the upper layer. Minerals are sent underground through vertical passages. Underground shovels are loaded in the loading area of the lower layer. Unloading work is carried out in the unloading area. The conveyor station is located in the unloading area, and the minerals are transported to the ground through the conveyor belt.

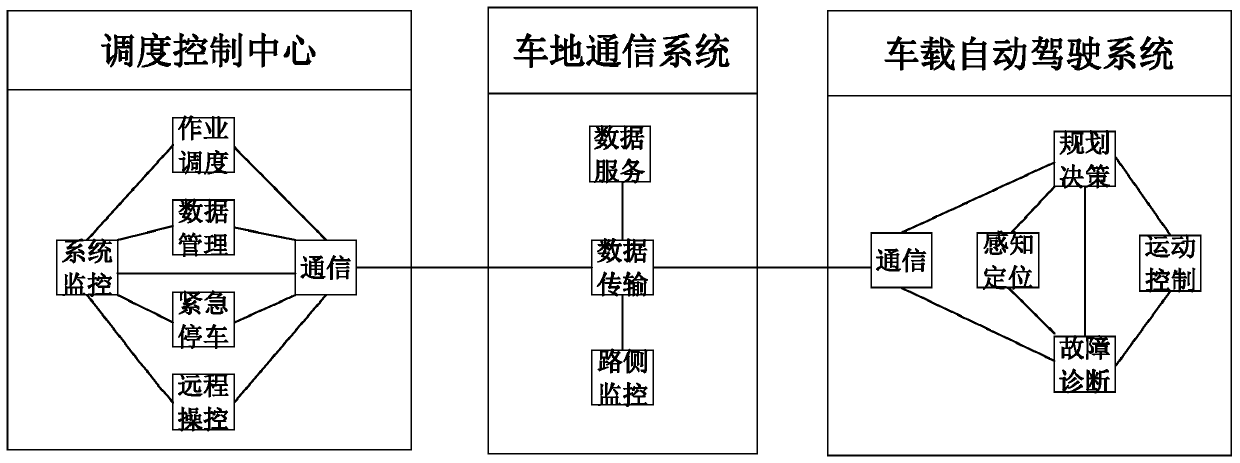

[0066] like figure 2 As shown, the fully automatic underground mining transportation system includes three aspects: dispatch control center, vehicle-ground communication system and vehicle-mounted automatic driving system.

[0067] 1. The dispatch control center mainly realizes the functions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com