Low-calorific-value high-strength cable support and manufacturing method thereof

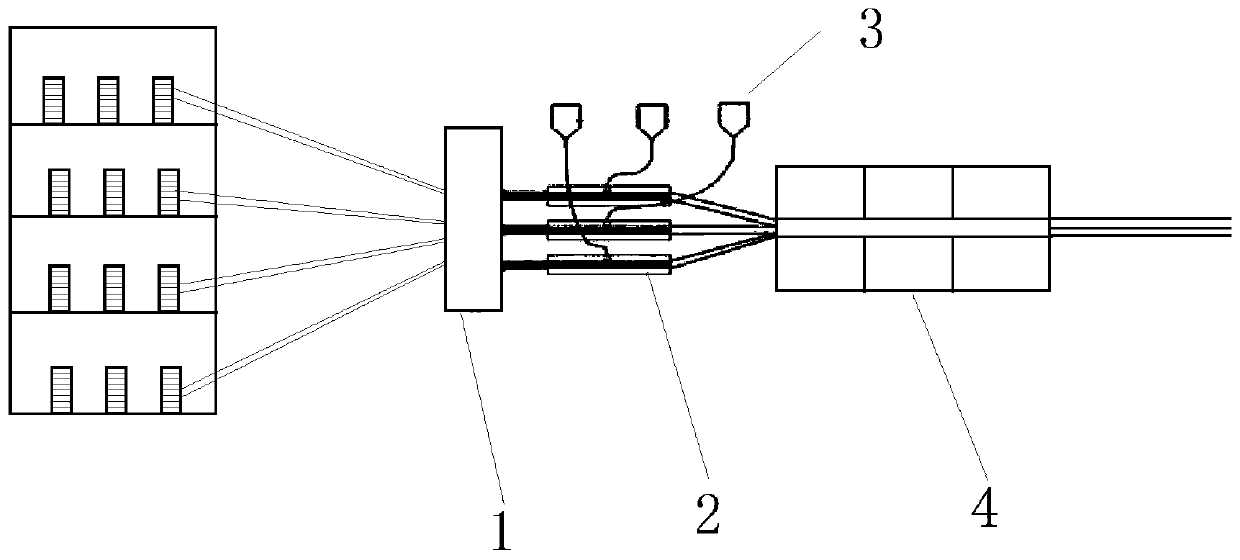

A cable support, high-strength technology, applied in the direction of electrical components, etc., can solve the problems of low strength of cable support, poor fire performance, inconvenient assembly, etc., and achieve the effect of high efficiency and energy saving in the preparation process, good fire performance, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

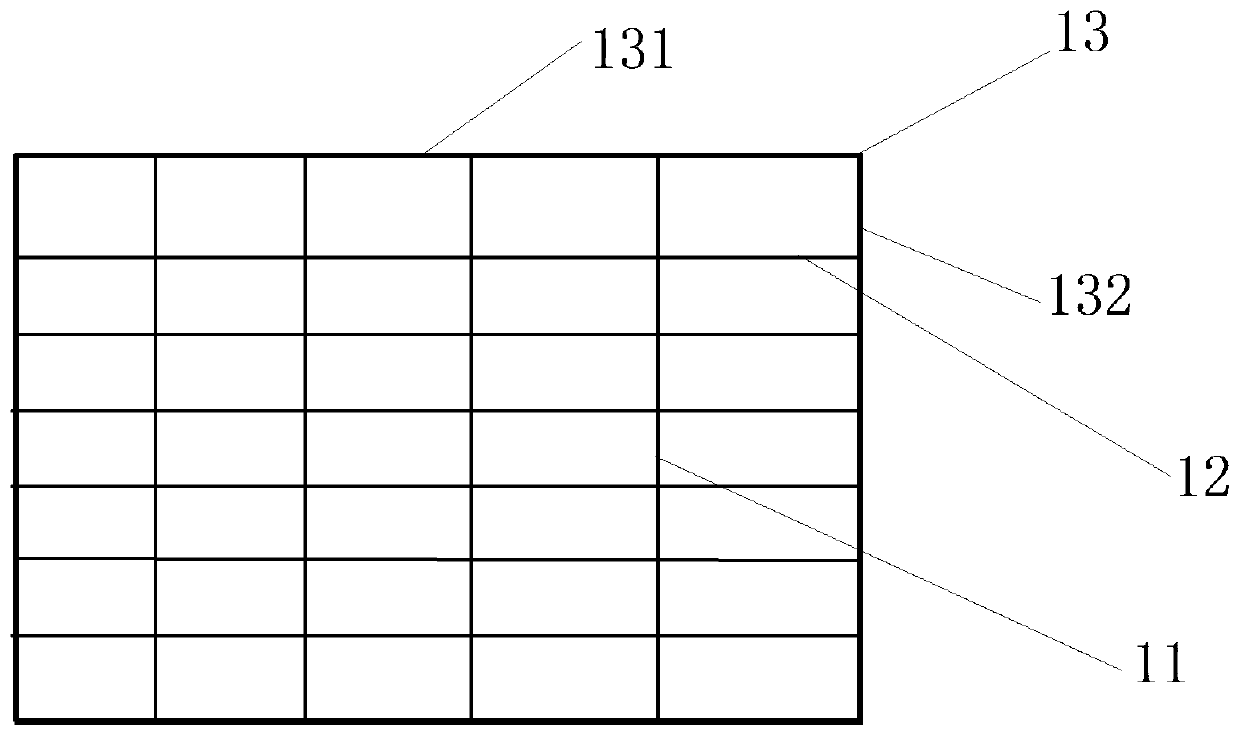

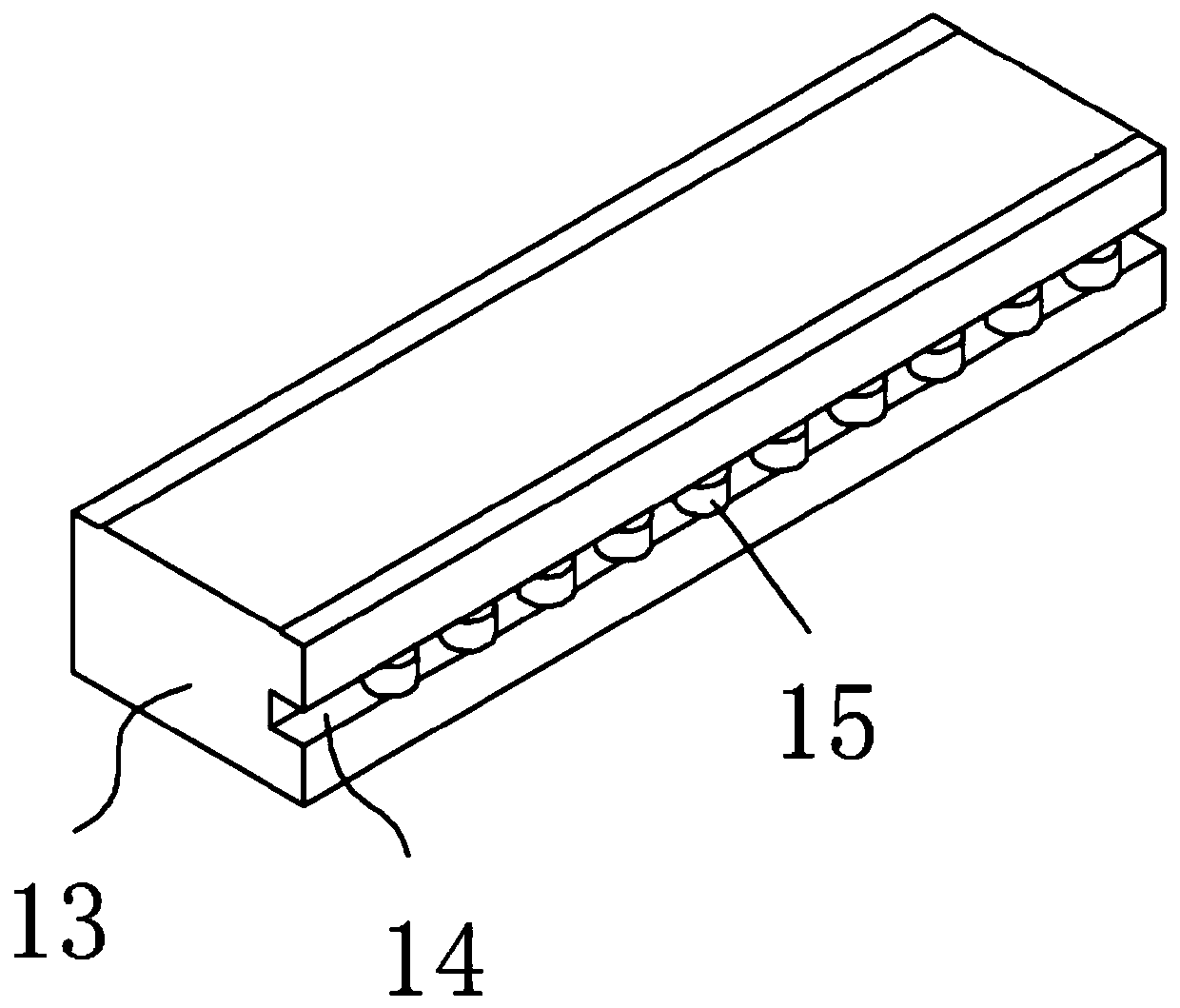

Method used

Image

Examples

preparation example Construction

[0047] Specifically, the present application provides a method for preparing a low thermal resistance high-strength cable support, the method comprising the steps of:

[0048] S1, preparing the base material;

[0049] S2, preparing the mixture: put 100 parts by weight of matrix material, 1-3 parts by weight of internal release agent and 30-60 parts by weight of inorganic powder into the stirring tank 3, stir evenly, and then add 1-2 parts of even Mixing agent, 30-60 parts by weight of inorganic powder, 3-5 parts of nano-montmorillonite, 1-3 parts of anti-ultraviolet agent and 5-10 parts by weight of chopped glass fiber, stir well to obtain the mixture;

[0050] S3, yarn application: pass the non-alkali continuous glass fiber through the dipping tank, so that the mixture is fully infiltrated with the non-alkali continuous glass fiber, and then extrude part of the mixture through the pressing roller, so that the total content of the glass fiber is between 70% and 75%. between; ...

Embodiment 1

[0126] A method for preparing a low calorific value and high strength cable support, the method comprising the steps of:

[0127] S1, prepare the base material: add 100 parts by weight of phenolic resin into the reaction kettle, stir and heat to 30° C., add 3 parts by weight of organosilicon prepolymer and 1 part by weight of sodium dihydrogen phosphate simultaneously, within 3min The temperature was raised to 60 °C, and after stirring at 60 °C for 10 min, the matrix material was obtained;

[0128] S2, prepare a mixture: put 100 parts by weight of matrix material, 1 part by weight of internal mold release agent and 30 parts by weight of inorganic powder into the stirred tank, stir evenly, then add 1 part by weight of coupling agent, 30 parts by weight of Inorganic powder, 3 parts of nano-montmorillonite, 1 part of anti-ultraviolet agent and 5 parts by weight of chopped glass fiber, stir well to obtain a mixture;

[0129] S3, yarn application: pass the non-alkali continuous glas...

Embodiment 2

[0136] A method for preparing a low calorific value high-strength cable support, said method comprising the steps of:

[0137] S1, preparation of matrix material: Add 100 parts by weight of phenolic resin into the reaction kettle, stir and heat to 50°C, then add 10 parts by weight of organosilicon prepolymer and 3 parts by weight of sodium dihydrogen phosphate at the same time, within 5min Raise the temperature to 60°C and stir at 60°C for 10 minutes to obtain the matrix material;

[0138] S2, preparing the mixture: put 100 parts by weight of matrix material, 3 parts by weight of internal release agent and 60 parts by weight of inorganic powder into the stirring tank, stir evenly, then add 2 parts of coupling agent, 60 parts by weight of Inorganic powder, 5 parts of nano-montmorillonite, 3 parts of anti-ultraviolet agent and 10 parts by weight of chopped glass fibers are stirred evenly to obtain the mixture;

[0139] S3, yarn application: pass the non-alkali continuous glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com