Seaweed feed and processing technology thereof

A processing technology and feed technology, applied in the field of feed, to achieve high hydrophilicity, improve the grade, and increase the viscosity of the feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

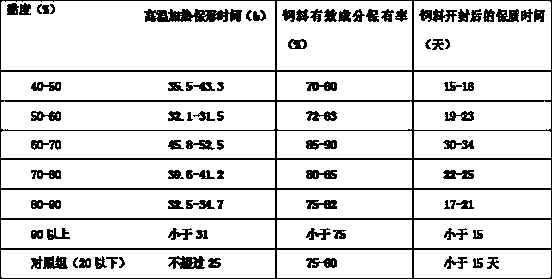

Examples

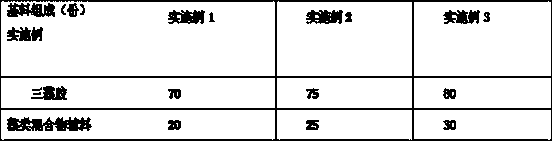

Embodiment 1

[0030] A seaweed feed, its raw materials are as follows in parts by weight: 70 parts of algae gel, 20 parts of algae mixture auxiliary materials, said algae gel is a mixture of sodium alginate, carrageenan and agar gum, and the mixing ratio is 2:1: 1. The sodium alginate is white or light yellow powder particles; the carrageenan is white or light brown powder particles; the agar is white or light brown gelatinous substance, and the algae mixture auxiliary material is fresh planktonic algae, the planktonic algae is a mixture of cyanobacteria, diatoms and green algae, the mixing ratio is 1:1:1.

[0031] The present invention also provides a processing technology of seaweed feed, comprising the steps of:

[0032] S1: Take the material, weigh the tri-alginate and the algae mixture auxiliary materials according to the parts by weight, and set aside;

[0033] S2: Refining, pouring the algae mixture auxiliary material into a grinder for grinding, grinding to form a slurry material, ...

Embodiment 2

[0045] A seaweed feed, its raw materials are as follows in parts by weight: 75 parts of tri-alginate, 25 parts of algae mixture auxiliary materials, said tri-alginate is a mixture of sodium alginate, carrageenan and agar gum, and the mixing ratio is 2:1: 1. The sodium alginate is white or light yellow powder particles; the carrageenan is white or light brown powder particles; the agar is white or light brown gelatinous substance, and the algae mixture auxiliary material is fresh planktonic algae, the planktonic algae is a mixture of cyanobacteria, diatoms and green algae, the mixing ratio is 1:1:1.

[0046] The present invention also provides a processing technology of seaweed feed, comprising the steps of:

[0047] S1: Take the material, weigh the tri-alginate and the algae mixture auxiliary materials according to the parts by weight, and set aside;

[0048] S2: Refining, pouring the algae mixture auxiliary material into a grinder for grinding, grinding to form a slurry mate...

Embodiment 3

[0060] A seaweed feed, its raw materials are as follows in parts by weight: 80 parts of tri-alginate, 30 parts of algae mixture auxiliary materials, the tri-alginate is a mixture of sodium alginate, carrageenan and agar gum, and the mixing ratio is 2:1: 1. The sodium alginate is white or light yellow powder particles; the carrageenan is white or light brown powder particles; the agar is white or light brown gelatinous substance, and the algae mixture auxiliary material is fresh planktonic algae, the planktonic algae is a mixture of cyanobacteria, diatoms and green algae, the mixing ratio is 1:1:1.

[0061] The present invention also provides a processing technology of seaweed feed, comprising the steps of:

[0062] S1: Take the material, weigh the tri-alginate and the algae mixture auxiliary materials according to the parts by weight, and set aside;

[0063] S2: Refining, pouring the algae mixture auxiliary material into a grinder for grinding, grinding to form a slurry mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com