Method for manufacturing titanium-and-titanium alloy high-pressure gas cylinder

A high-pressure gas cylinder and a manufacturing method technology, which are applied in the manufacture of container structures, pressure vessels, ship construction details, etc., can solve problems such as low heating temperature, eliminate wrinkles, improve impact performance and tensile performance, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

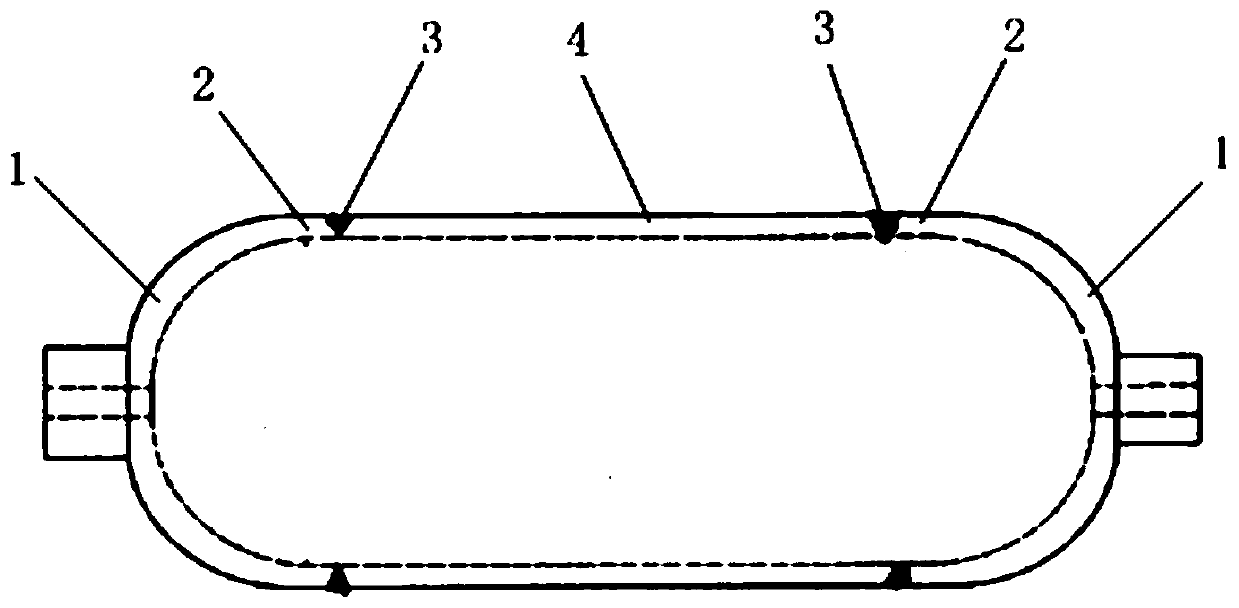

[0033] The embodiment of the present invention is based on TC4 alloy, provides a kind of manufacturing method of the TC4 titanium alloy high-pressure gas cylinder of three-stage welding, and this manufacturing method comprises the following steps:

[0034] Step 1: Process the TC4 alloy bar into the first semi-finished head section by die forging process, and ensure that the structure and performance of the first semi-finished head section meet the design requirements, and then adopt the method of mechanical processing to process the first semi-finished product The inner and outer surfaces of the head section are processed according to the process requirements to obtain the second semi-finished head section with higher dimensional accuracy and lower surface roughness; the second semi-finished head section is composed of a head and a straight pipe.

[0035] Step 2: Prepare a pipe section by forging process, and process the inner and outer surfaces of the pipe section by mechanica...

Embodiment 2

[0054] The embodiment of the present invention is based on TC4 alloy, provides a kind of manufacturing method of the finished product of TC4 titanium alloy high-pressure gas cylinder of a kind of two-stage welding, and this manufacturing method comprises the following steps:

[0055] Step 1: Process the TC4 alloy bar into the first semi-finished head section by die forging process, and ensure that the structure and performance of the first semi-finished head section meet the design requirements, and then adopt the method of mechanical processing to process the first semi-finished product The inner and outer surfaces of the head section are processed to obtain a second semi-finished head section with higher dimensional accuracy and lower surface roughness; the second semi-finished head section is composed of a head and a straight pipe.

[0056] Step 2: According to the method of step 1, prepare two second semi-finished head sections, open the straight pipe ends of the two semi-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com