Airship structure design method based on air bag diaphragm and inflatable ring framework

A technology of structural design and design method, which is applied in the direction of airbag layout, aircraft parts, ground equipment, etc., can solve the problems that the deformation of the main bag body cannot be effectively controlled, and the operation mechanism is not considered, so as to achieve obvious practical significance and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

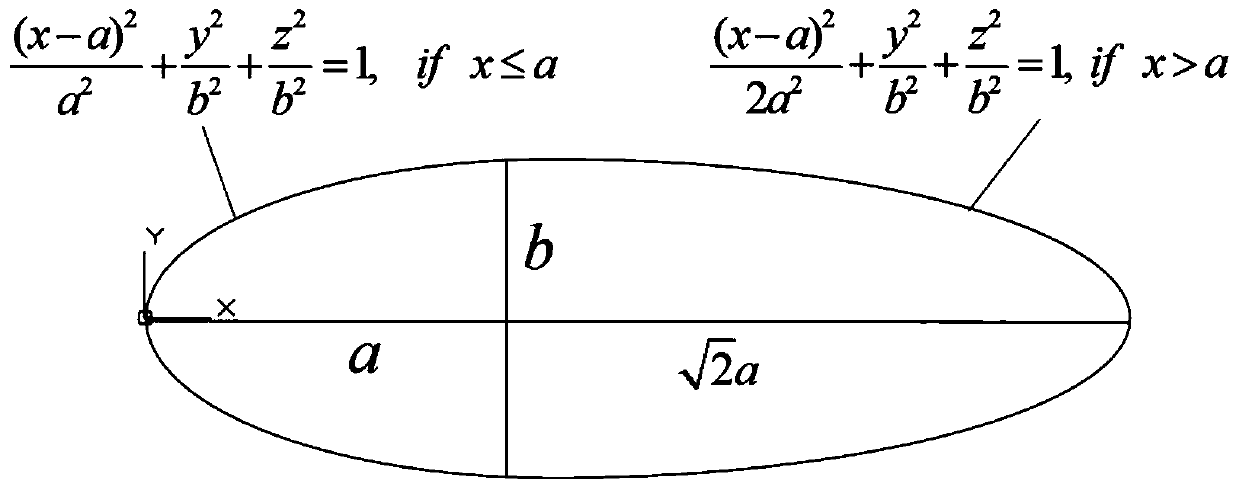

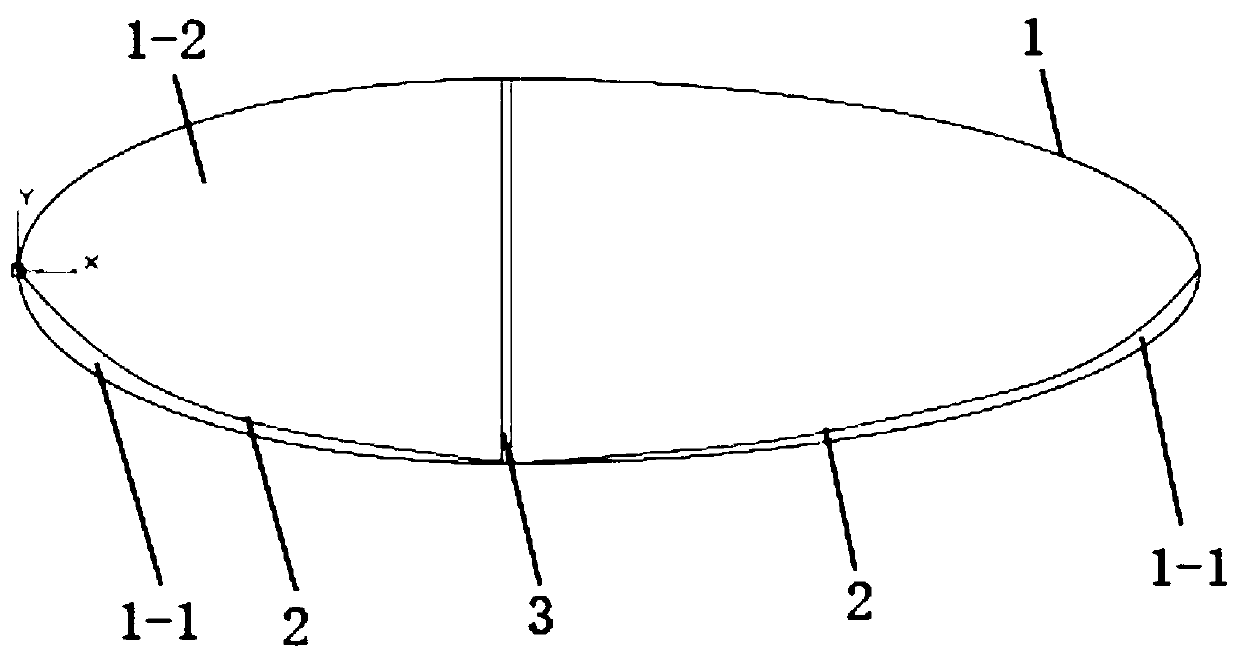

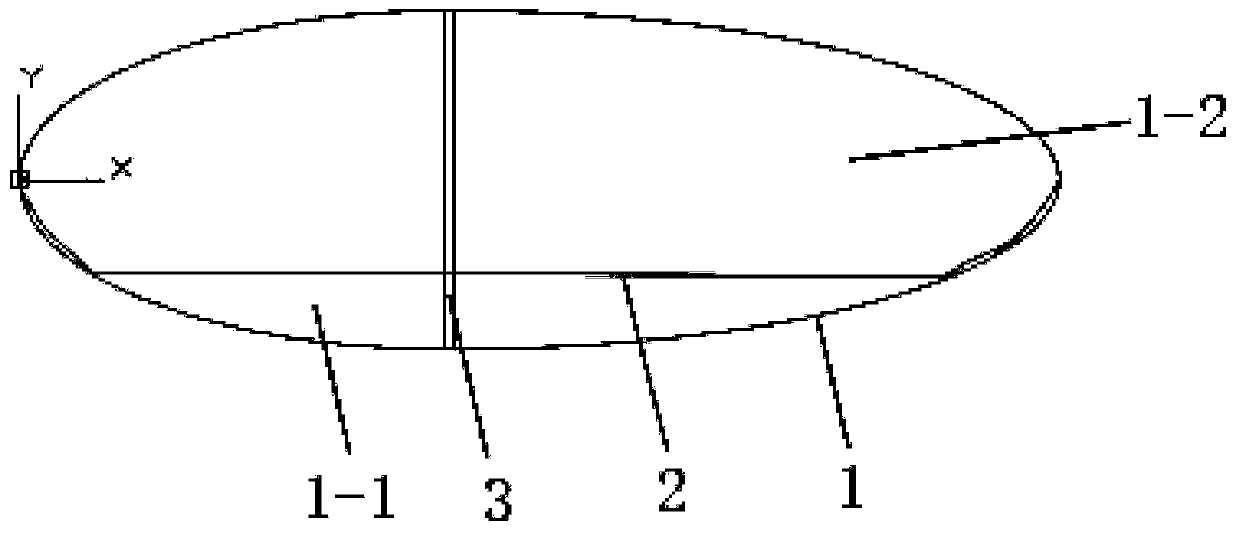

[0020] Specific implementation mode one: as Figure 1 to Figure 10 As shown, the present invention discloses a method for designing an airship structure based on an airbag diaphragm and an inflatable ring skeleton. The design method includes:

[0021] The configuration of the main capsule 1 of the airship adopts the design of double ellipse generatrix turning into a body. A diaphragm 2 is arranged inside the main capsule 1. The diaphragm 2 can be freely expanded and the edge of the diaphragm 2 is sealed and fixedly connected with the inner wall of the main capsule 1. The diaphragm 2 and the part surrounded by the lower diaphragm 2 of the main capsule body 1 forms an air bag 1-1, and the interior of the main bag body 1 is located above the diaphragm 2 as a helium gas existence area 1-2, and the air bag 1-1 and the helium gas existence area 1-2 Alternate inflation and deflation to change the pressure and volume, control the ascent and descent of the airship, and arrange a plural...

specific Embodiment approach 2

[0022] Specific implementation mode two: as Figure 8 As shown, this embodiment is a further description of Embodiment 1. The inflatable ring 3 is made of vectran fabric material, and the connecting cable 3-1 is made of Kevlar.

specific Embodiment approach 3

[0023] Specific implementation mode three: as Figure 5 As shown, this embodiment is a further description of Embodiment 1. The diaphragm 2 uses UHMWPE fiber 50D fabric as the load-bearing layer, and the polyenol functional film as the gas barrier film. The material surface of the load-bearing layer The density is 0.97g / cm 3 , The fiber specific strength is 3196kg m / kg, and the material surface density of the gas barrier film is 15g / cm 3 , helium permeability rate 0.18L / m 2 .24h. atm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com